N-(phosphonic acid methyl) glycine rare earth charring agent as well as preparation method and application thereof

A technology of phosphonic acid methyl and glycine, which is applied in the field of flame retardant materials, can solve problems such as residues, non-target biological toxicity, human health and fertility threats, and achieve the effects of easy control, good flame retardant effect, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

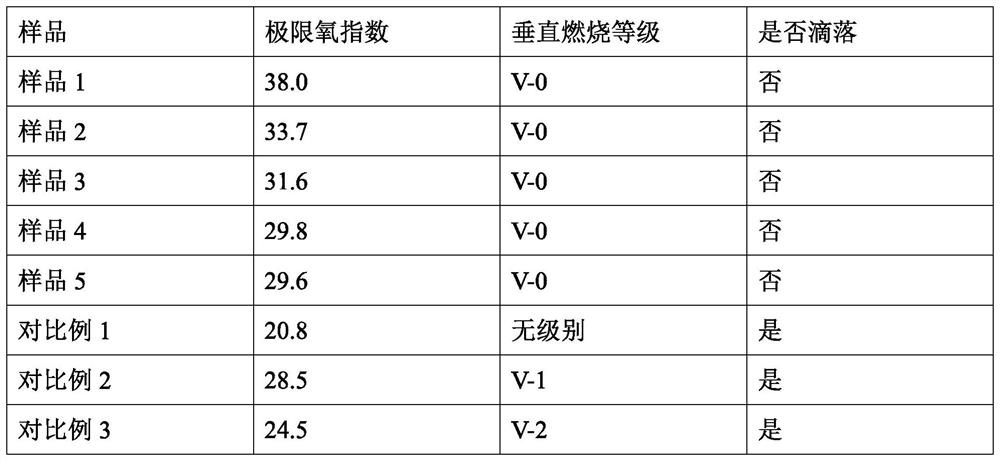

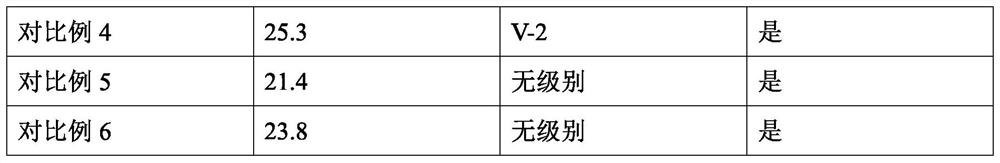

Embodiment 1

[0038] Take 74 parts of polylactic acid, 15 parts of piperazine pyrophosphate, 10 parts of N-(phosphonic acid methyl) glycine rare earth char-forming agent, 0.5 part of antioxidant, and 0.5 part of lubricant into a mixer and mix evenly. Then put it into a twin-screw extruder for melt blending, extrusion and granulation. The extrusion temperature is 165°C, 175°C, 180°C, 180°C, 180°C, 180°C, 175°C, which is designated as sample 1. Wherein, the antioxidant is zinc dialkyldithiophosphate, the lubricant is EBS, and the flame retardant test is carried out according to the test standards of ASTMD 3801 and ASTMD 2863-97.

Embodiment 2

[0040] Take 79 parts of polylactic acid, 10 parts of piperazine pyrophosphate, 10 parts of N-(phosphonic acid methyl)glycine rare earth char-forming agent, 0.5 part of antioxidant, and 0.5 part of lubricant into a mixer and mix evenly. Then put it into a twin-screw extruder for melt blending, extrusion and granulation. The extrusion temperature is 165°C, 175°C, 180°C, 180°C, 180°C, 180°C, 175°C, which is designated as sample 2. Wherein, the antioxidant is zinc dialkyldithiophosphate, the lubricant is EBS, and the flame retardant test is carried out according to the test standards of ASTMD 3801 and ASTMD 2863-97.

Embodiment 3

[0042] Take 84 parts of polylactic acid, 10 parts of piperazine pyrophosphate, 5 parts of N-(phosphonic acid methyl) glycine rare earth char-forming agent, 0.5 part of antioxidant, and 0.5 part of lubricant into a mixer and mix evenly. Then it was added into a twin-screw extruder for melt blending, extrusion and granulation. The extrusion temperature was 165°C, 175°C, 180°C, 180°C, 180°C, 180°C, 175°C, which was designated as sample 3. Wherein, the antioxidant is zinc dialkyldithiophosphate, the lubricant is EBS, and the flame retardant test is carried out according to the test standards of ASTMD 3801 and ASTMD 2863-97.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com