Purification method of madecassoside

A technology of madecassoside and a purification method, which is applied in the field of purification of madecassoside, can solve the problems of inapplicability to industrialized production, large amount of solvent used, and high production cost, and achieve low production cost, high product yield and high production cost. The effect of high purity and low requirements for equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

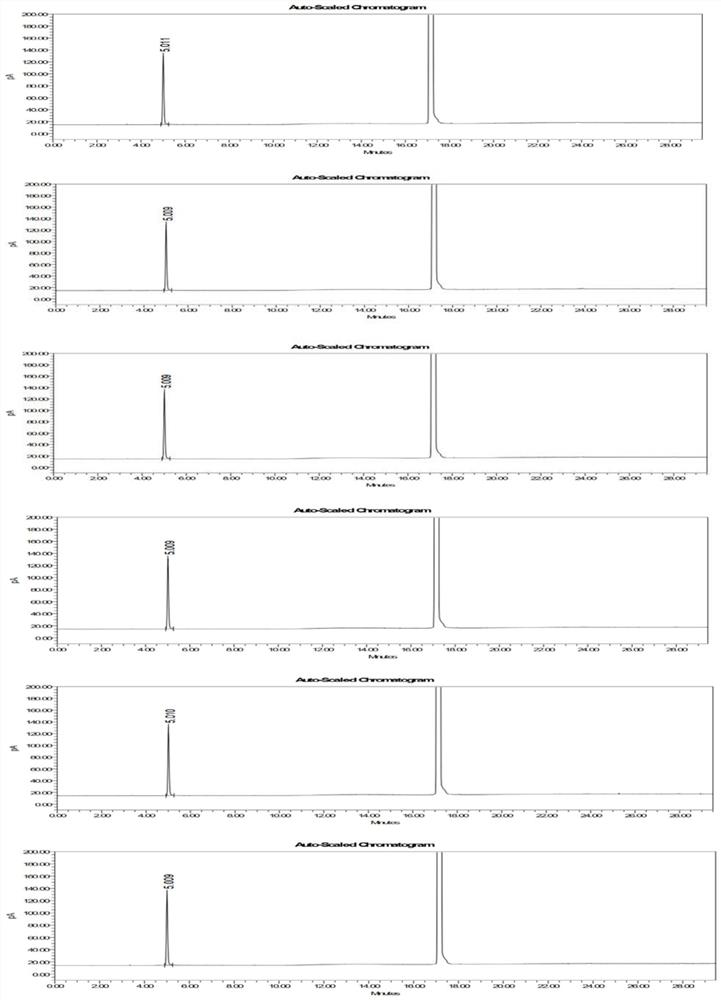

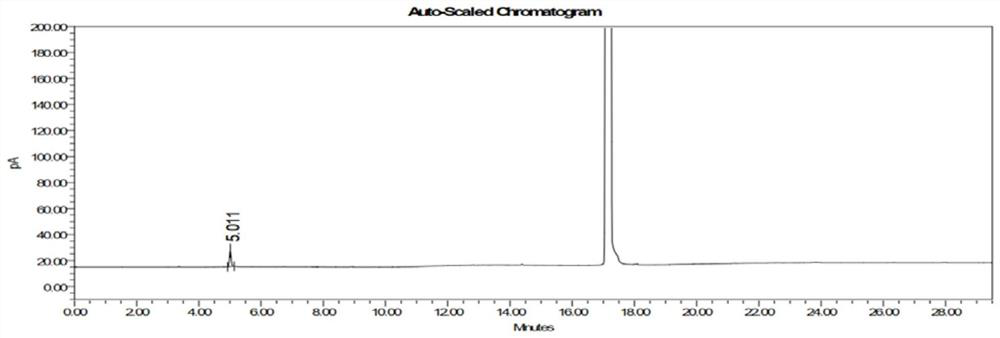

Embodiment 1

[0087] Add 300mL of anhydrous methanol and 20.00g of madecassoside to a 500ml reaction bottle in sequence, stir and mix for 10-15 minutes, stir and heat up to 60°C, after the complete dissolution of madecassoside, put the crystal system at 50°C, P Concentrate until the system reaches 8V under the condition of ≤-0.08MPa, then stop the concentration. Add 0.20g madecassoside to the crystallization system, naturally cool down to 25°C, heat and crystallize for 0.5-1.0 hours, filter the reaction system, take a sample of the filter cake for HPLC detection, after the relevant content is greater than 90%, put the filter cake at 55 Vacuum drying at -60°C and P≤-0.08MPa for 8-10 hours to obtain 16.2 g of refined madecassoside with a purity of 91.58%.

Embodiment 2

[0089] Add 360mL of anhydrous methanol and 20.00g of madecassoside to a 500ml reaction bottle in sequence, stir and mix for 10-15 minutes, stir and heat up to 65°C, after the complete dissolution of madecassoside, put the crystal system at 50°C, P Concentrate until the system reaches 7V under the condition of ≤-0.08MPa, then stop the concentration. Add 0.20g madecassoside to the crystallization system, naturally cool down to 25°C, heat and crystallize for 0.5-1.0 hours, filter the reaction system, and dry the filter cake in vacuum at 55-60°C, P≤-0.08MPa for 8- After 10 hours, 17.0 g of refined madecassoside was obtained with a purity of 91.00%.

Embodiment 3

[0091] Add 200mL of anhydrous methanol and 20.00g of madecassoside to a 500ml reaction bottle in turn, stir and mix for 10-15 minutes, stir and heat up to 60°C, after the complete dissolution of madecassoside, put the crystal system at 45°C, P Concentrate until the system reaches 8V under the condition of ≤-0.08MPa, then stop the concentration. Add 0.20g madecassoside to the crystallization system, naturally cool down to 20°C, heat and crystallize for 0.5-1.0 hours, filter the reaction system, and dry the filter cake in vacuum at 55-60°C, P≤-0.08MPa for 8- After 10 hours, 16.1 g of refined madecassoside was obtained with a purity of 90.42%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com