Preparation method of high-bonding-strength EVA film for glass fiber reinforced plastic interlayer

A high-adhesion, FRP technology, applied in the direction of adhesives, adhesive types, heat-activated films/sheets, etc., can solve problems such as not meeting the requirements of use, and achieve good reactivity and compatibilization effects, high cohesion, and good thermal adhesion Relay effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

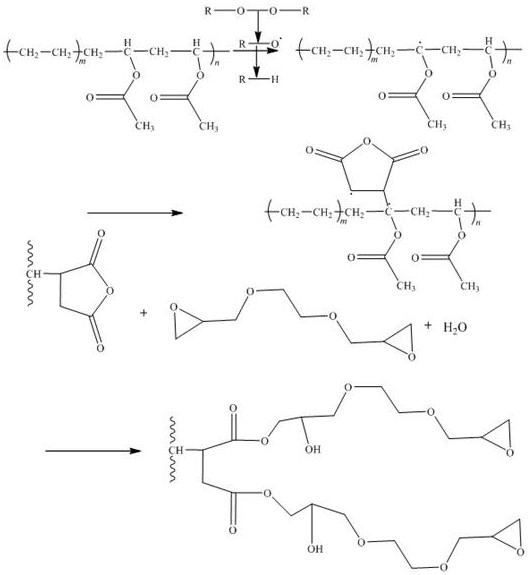

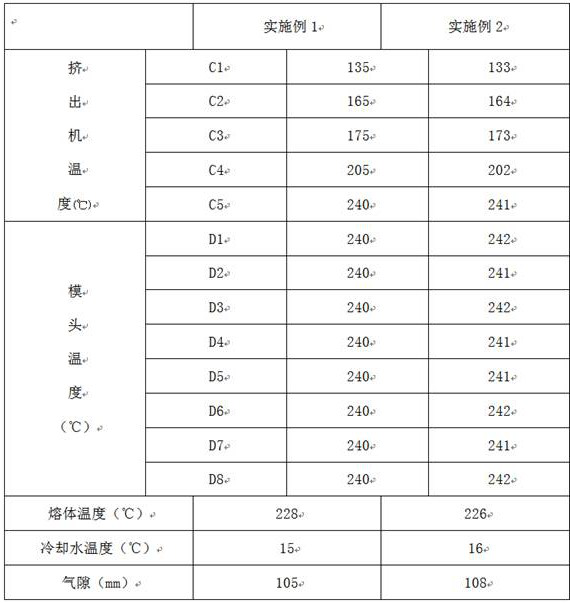

[0017] At first, the preparation macromolecular coupling agent is to be by in the reactor with agitator, dropping funnel, add 40 parts of EVA of parts by weight, the maleic anhydride of 18 parts and the solvent toluene of 350 parts, in Under the protection of nitrogen, heat and stir to dissolve. Under reflux, add 1.2 parts of dicumyl peroxide toluene solution with a mass fraction of 0.25% dropwise, stir for 90 minutes, cool to 30°C, and then add 35 parts of deionized water to the reaction kettle In the process, heat up to 120°C, heat and keep the temperature at 600rpm and stir for 2 hours, add 8 parts of ethylene glycol glycidyl ether and 0.4 parts of 2-methylimidazole, continue stirring for 2 hours, after the reaction is over, the product is precipitated by methanol and suction filtered The obtained white powder; secondly, the EVA premix is ethylene-vinyl acetate copolymer 115phr, Guangdong Baolin chemical industry grade BL-1180 hydrogenated rosin glyceride 0.8phr, grade PEH...

Embodiment 2

[0020]At first, the preparation macromolecular coupling agent is to be by in the reactor that has stirrer, dropping funnel, adds 35 parts of EVAs of parts by weight, the maleic anhydride of 14 parts and the solvent toluene of 300 parts, in Under the protection of nitrogen, heat and stir to dissolve. Under reflux, add 1.0 parts of dicumyl peroxide toluene solution with a mass fraction of 0.25% dropwise, stir for 80 minutes, cool to 25°C, and then add 30 parts of deionized water to the reaction kettle In the process, heat up to 110°C, heat and maintain a constant temperature of 600rpm and stir for 2 hours, add 8 parts of ethylene glycol glycidyl ether and 0.3 parts of 2-methylimidazole, continue stirring for 1 hour, after the reaction is over, the product is precipitated by methanol and suction filtered The white powder that obtains; Secondly, the EVA premix is ethylene-vinyl acetate copolymer 108phr, Guangdong Baolin Chemical brand BL-1180 hydrogenated rosin glyceride 0.6phr, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com