Environment-friendly modified benzoxazine resin and preparation method thereof

A benzoxazine and environment-friendly technology, which is applied in the field of environment-friendly modified benzoxazine resin and its preparation, can solve the problem of low carbon residue rate of benzoxazine resin, low molecular regularity of resin, and uneven molecular weight distribution. Concentration and other issues to achieve the effect of improving heat resistance, improving resin thermal stability and mechanical properties, and good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

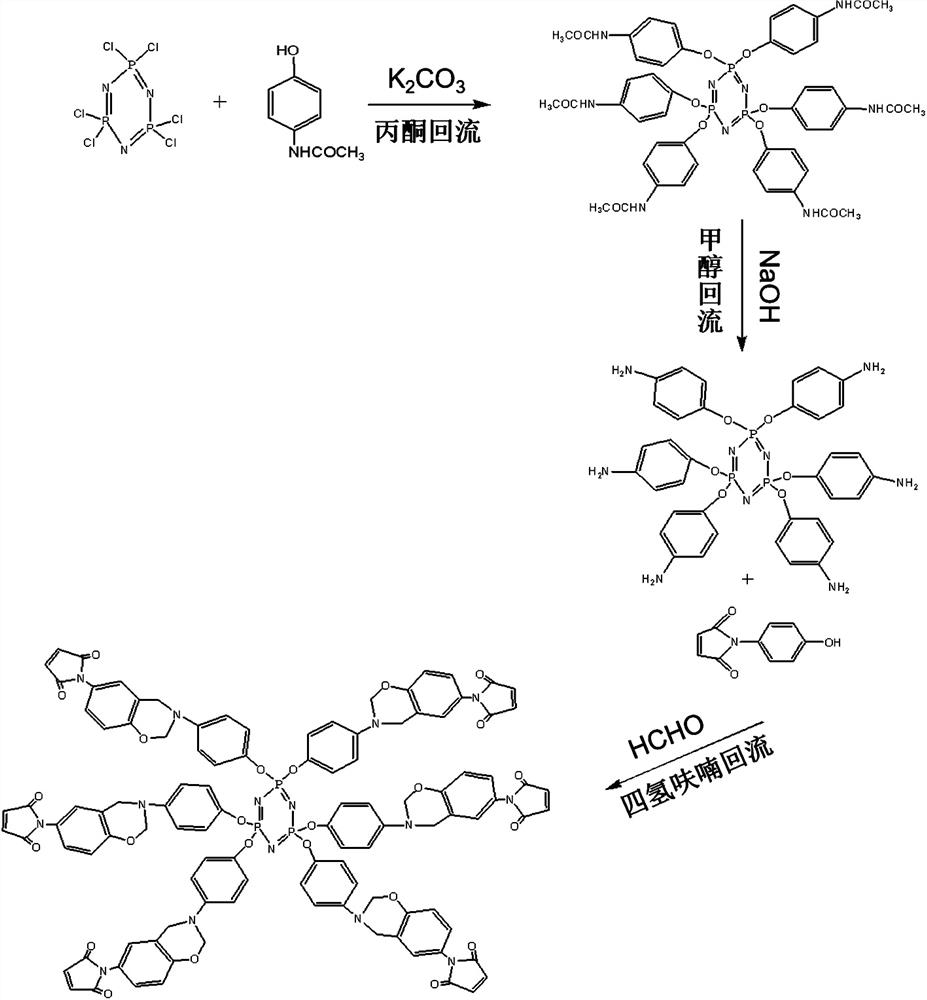

[0032] In this embodiment, the present invention provides an environmentally friendly modified benzoxazine resin and a preparation method thereof. The present invention provides an environmentally friendly modified benzoxazine resin, which comprises: six 35 parts of chlorocyclotriphosphazene, 70 parts of paracetamol, 70 parts of 4-maleimidophenol and 90 parts of formaldehyde; calculated in parts by mass, the catalyst includes: 4 parts of potassium carbonate, 0.2 parts of sodium hydroxide ; The solvent is acetone, methanol, tetrahydrofuran.

[0033] Specifically include the following steps:

[0034] S1. Add solvent acetone, 35 parts of hexachlorocyclotriphosphazene and 70 parts of p-acetaminophen to the reaction kettle and stir to fully dissolve, then add 4 parts of catalyst potassium carbonate, heat for the first time, and the solution boils when the temperature rises to 60°C , carry out the first reflux reaction, the reflux reaction time is 24h, the reflux reaction is comple...

Embodiment 2

[0056] In this embodiment, the present invention provides an environmentally friendly modified benzoxazine resin and a preparation method thereof. The present invention provides an environmentally friendly modified benzoxazine resin, which comprises: six 25 parts of chlorocyclotriphosphazene, 60 parts of paracetamol, 75 parts of 4-maleimidophenol and 80 parts of formaldehyde; calculated by mass parts, the catalyst includes: 4 parts of potassium carbonate, 0.2 parts of sodium hydroxide ; The solvent is acetone, methanol, tetrahydrofuran.

[0057] Specifically include the following steps:

[0058] S1. Add solvent acetone, 25 parts of hexachlorocyclotriphosphazene and 60 parts of p-acetaminophen to the reaction kettle, stir and dissolve fully, then add 4 parts of catalyst potassium carbonate, heat for the first time, and the solution boils when the temperature rises to 57°C , carry out the first reflux reaction, the reflux reaction time is 28h, the reflux reaction is completed, ...

Embodiment 3

[0062] In this embodiment, the present invention provides an environmentally friendly modified benzoxazine resin and a preparation method thereof. The present invention provides an environmentally friendly modified benzoxazine resin, which comprises: six 40 parts of chlorocyclotriphosphazene, 75 parts of paracetamol, 80 parts of 4-maleimidophenol and 100 parts of formaldehyde; calculated in parts by mass, the catalyst includes: 4 parts of potassium carbonate, 0.2 part of sodium hydroxide ; The solvent is acetone, methanol, tetrahydrofuran.

[0063] Specifically include the following steps:

[0064] S1. Add solvent acetone, 40 parts of hexachlorocyclotriphosphazene and 75 parts of p-acetaminophen to the reaction kettle, stir and dissolve fully, then add 4 parts of catalyst potassium carbonate, heat for the first time, and the solution boils at 65°C , carry out the first reflux reaction, the reflux reaction time is 36h, the reflux reaction is completed, the first time the tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com