Flexible single-crystal superconducting thin film, preparation method thereof and superconducting device

A technology of superconducting thin films and single crystals, which is applied in the manufacture/processing of superconducting devices, superconducting components, and superconducting devices, and can solve the problem of inability to obtain flexible and single-crystal superconducting thin films and the inability to withstand the growth temperature and other problems, to achieve excellent thermal stability, process controllability, and expand the effect of application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

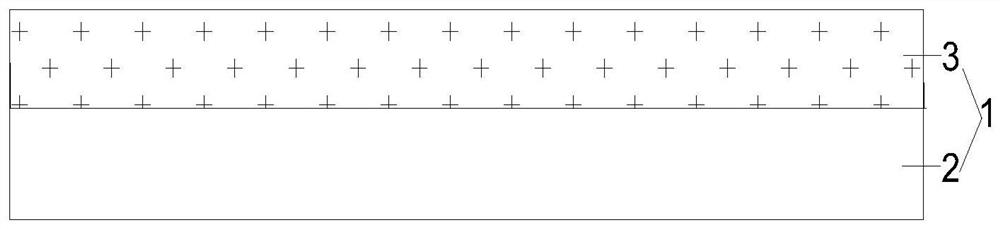

[0027] Based on this, the preparation method of the flexible single crystal superconducting thin film provided by the application comprises the following steps:

[0028] S1, providing single crystal fluorophlogite;

[0029] S2, using the single crystal fluorine phlogopite as the substrate, the transition metal as the target, and nitrogen as the reaction gas, under vacuum conditions, adopting a reactive sputtering method to epitaxially grow a transition metal nitride film on the substrate, wherein, In the reactive sputtering method, the temperature of the substrate is 700°C-900°C, the flow rate of the nitrogen gas is 2sccm-10sccm, and the transition metal nitride thin film is a single crystal thin film;

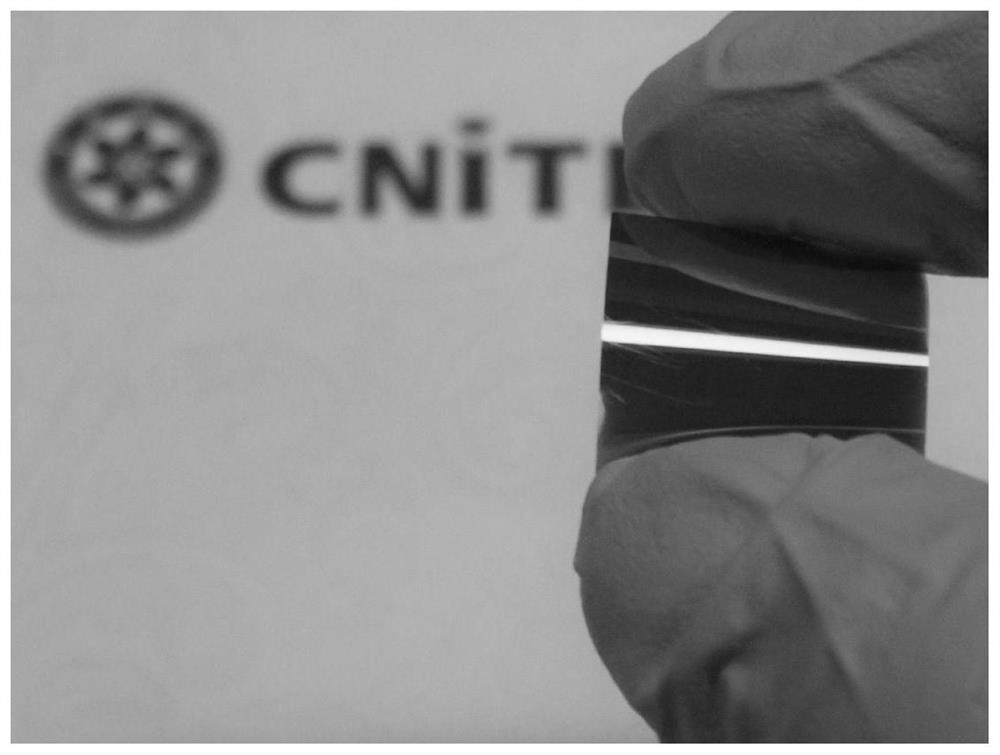

[0030] S3, thinning the substrate with the transition metal nitride thin film, so that the thickness of the substrate is less than or equal to 50 μm, to obtain a flexible superconducting thin film.

[0031] In order to prevent the impurities on the fluorophlogopite placed in ...

Embodiment 1

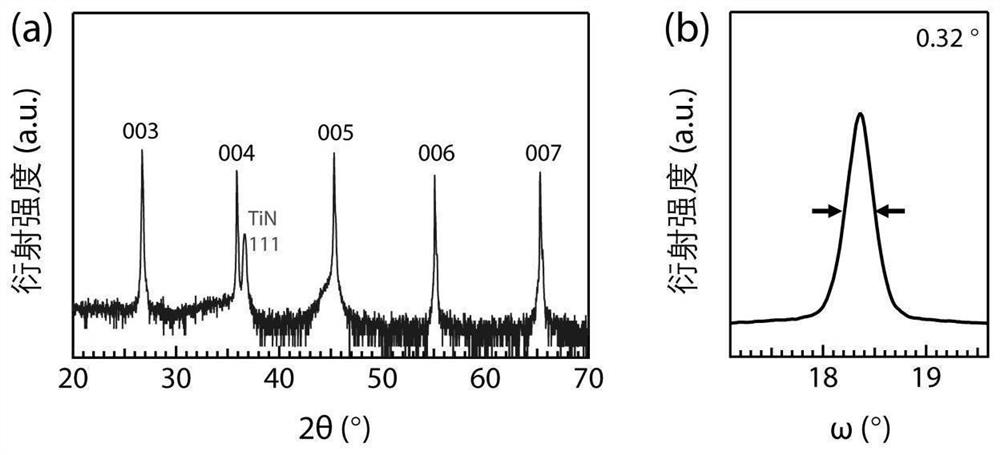

[0063] A titanium nitride thin film with a thickness of 80nm was prepared using fluorophlogopite as a substrate.

[0064] Provide 2cm*2cm fluorophlogopite as a substrate, use analytical grade acetone and alcohol solution to ultrasonically clean for 5 minutes, and blow dry with a nitrogen gun.

[0065] Load the cleaned substrate on the heating table in the sputtering chamber, and draw a vacuum until the vacuum degree reaches 1*10 - 6 Below Torr, turn on the power of the heating platform, set the temperature at 800°C, and bake the substrate for 30 minutes.

[0066] Introduce ultra-pure nitrogen gas into the sputtering chamber, and then start the mechanical pump and turbomolecular pump to evacuate to 1*10 -6 Torr, perform gas washing operation on the sputtering chamber and gas pipeline to remove impurity gas, and cycle 2 times. After the gas scrubbing, continue to draw vacuum until the background vacuum of the sputtering chamber reaches 1*10 -7 Torr ends pumping below.

[00...

Embodiment 2

[0073] A niobium nitride thin film with a thickness of 500nm was prepared using fluorophlogopite as a substrate.

[0074] Provide 3cm*3cm fluorophlogopite as the substrate, use analytical grade acetone and alcohol solution to ultrasonically clean for 10min, and blow dry with nitrogen gun.

[0075] Load the cleaned substrate on the heating table in the sputtering chamber, and draw a vacuum until the vacuum degree reaches 1*10 - 6 Below Torr, turn on the power of the heating platform, set the temperature at 800°C, and bake the substrate for 30 minutes.

[0076] Introduce ultra-pure nitrogen gas into the sputtering chamber, and then start the mechanical pump and turbomolecular pump to evacuate to 1*10 -6 Torr, wash the sputtering chamber and gas pipeline to remove impurity gas, and cycle 3 times. After the gas scrubbing, continue to draw vacuum until the background vacuum of the sputtering chamber reaches 1*10 -7 Torr ends pumping below.

[0077] Control the flow of ultra-pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com