Segmented injection self-clamping IGBT device and manufacturing method thereof

A segmented and device technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of reducing on-resistance, increasing Miller capacitance, and degradation of breakdown characteristics, so as to improve conduction Increased resistance, reduced saturation current, and improved bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

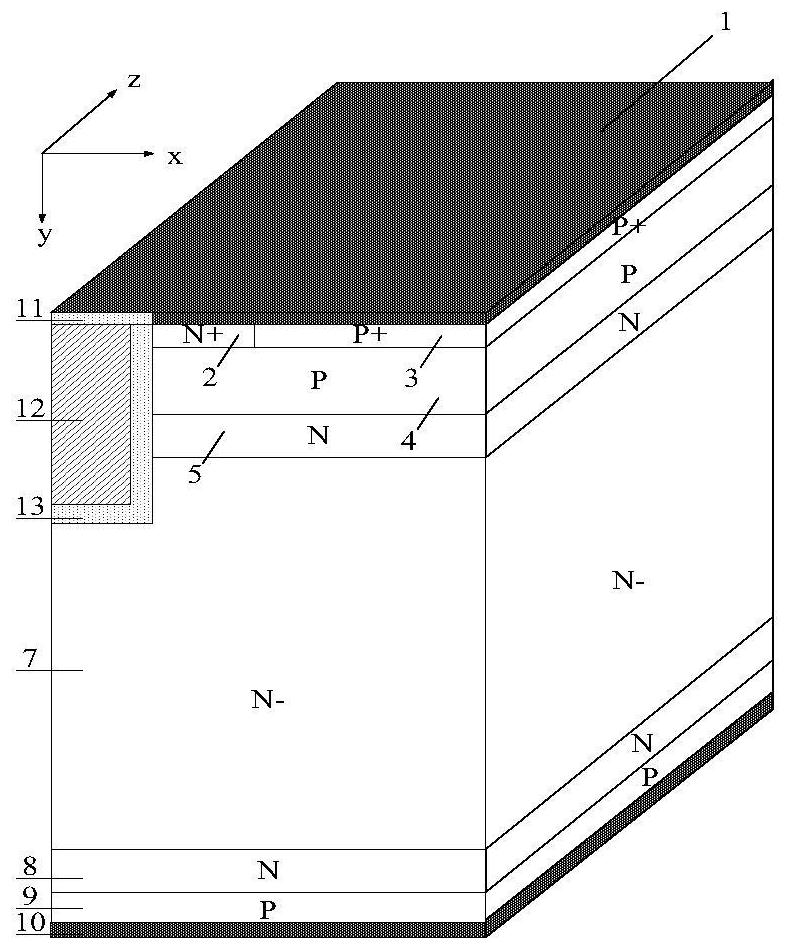

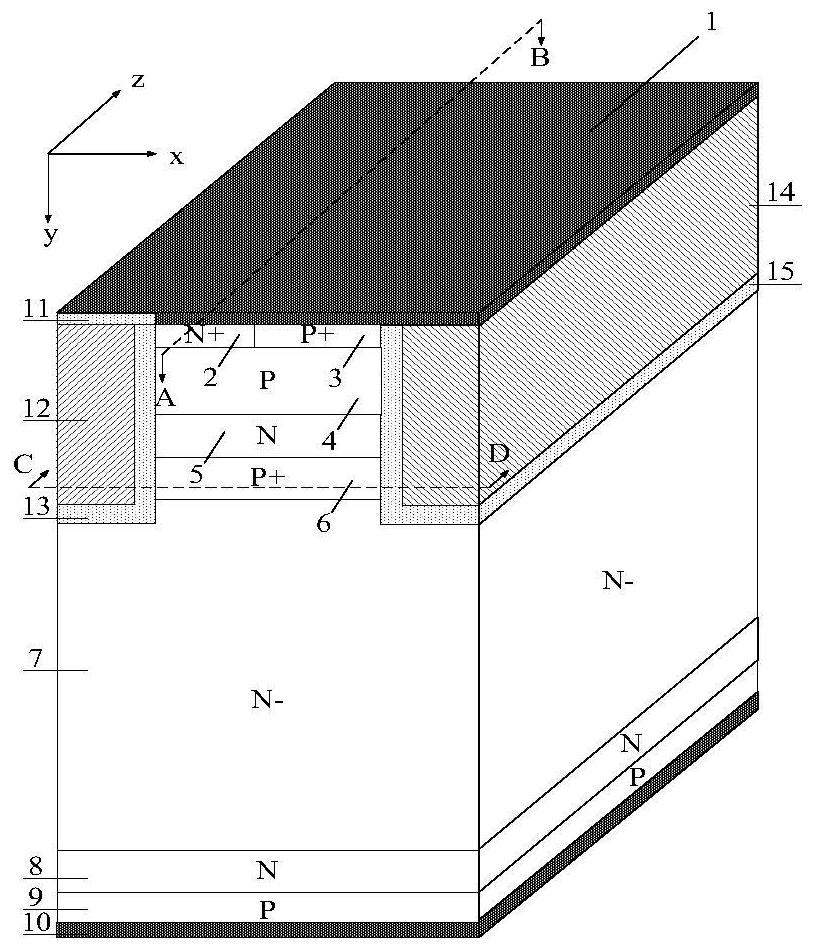

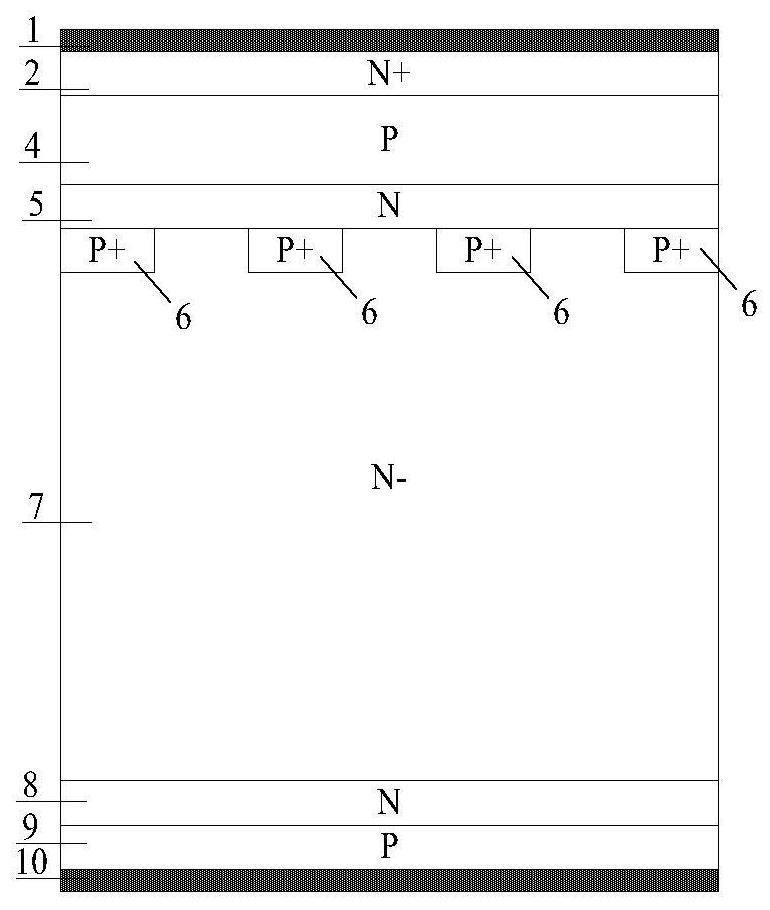

[0076] An embodiment of a segmented injection self-clamping IGBT device, its half-cell structure and the cross-section along the AB line and the CD line are as follows figure 2 , 3 , 4, including a collector metal 10, a P-type collector region 9, an N-type field stop layer 8, and an N-drift region 7 stacked sequentially from bottom to top, and a trench structure located above the N-drift region 7, The trench structure includes a gate dielectric layer 13, a polycrystalline gate electrode 12 in the gate dielectric layer 13, and a gate isolation dielectric layer 11 above the polycrystalline gate electrode 12;

[0077] It is characterized in that there is a P+ buried layer 6 and a separation gate structure above the N-drift region 7, and the separation gate structure includes a separation gate dielectric layer 15 and a polycrystalline separation gate electrode 14 in the separation gate dielectric layer 15;

[0078] Define the 3-dimensional direction of the device in a 3-dimension...

Embodiment 2

[0090] On the basis of Embodiment 1, a segmented implanted self-clamping IGBT device embodiment is proposed. The difference between this embodiment and Embodiment 1 lies in: the gap between any two adjacent P+ buried layers 6 along the Z direction The N-drift region 7 is replaced by a P-buried layer 16; the width of the P-buried layer 16 along the Z direction is less than or equal to the width of the P+ buried layer 6 along the Z direction; the concentration of the P-buried layer 16 is less than or equal to The concentration of the P-type base region 4 and the width of the P- buried layer 16 along the y direction are the same as the width of the P+ buried layer 6 along the y direction.

[0091] Its semi-cellular structure and the section along AB line and CD line are as follows Figure 5 , 6 As shown in , 7, a step is added between step 4 and step 5 in its manufacturing process: P-type buried layer 16 is formed by ion implantation of P-type impurities, and the rest of the pro...

Embodiment 3

[0104] On the basis of Embodiment 1, a segmented implanted self-clamping IGBT device embodiment is proposed. The difference between this embodiment and Embodiment 1 is that a super junction N column 17 and a super The super junction structure formed by junction P pillars 18. Its semi-cellular structure and the section along AB line and CD line are as follows Figure 8 , 9 , as shown in 10,

[0105] The introduction of the superjunction structure further reduces the conduction voltage drop of the device and increases the breakdown voltage of the device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com