Thermal repair coating and preparation method and application thereof

A technology for thermal repair and paint, applied in the field of paint, can solve the problems of inability, insufficient thermal repair performance, no self-repair function, etc., and achieve the effect of simple synthesis operation and easy to obtain.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

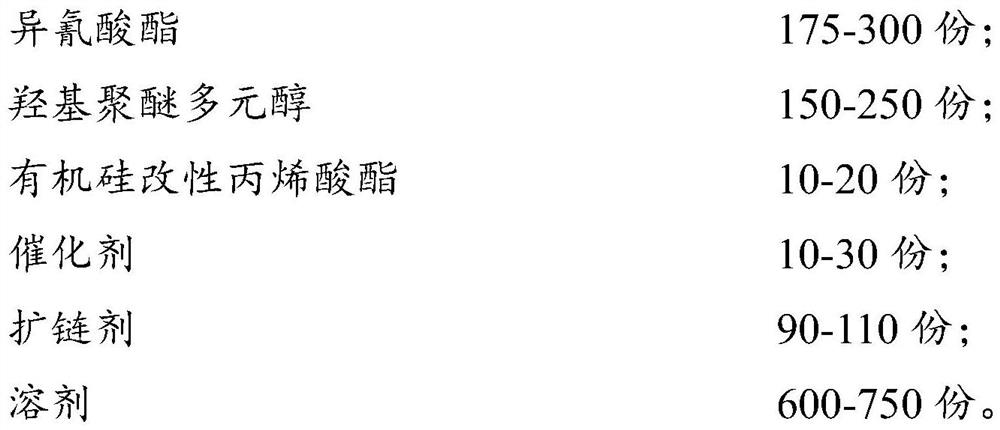

Embodiment 1

[0035] This embodiment provides a heat repair coating, which is prepared from the following raw materials in parts by weight: 200 parts of isocyanate, 192 parts of hydroxyl polyether polyol, 20 parts of silicone modified acrylate, 10 parts of catalyst, and chain extender 102 parts, 5 parts of antioxidant, 8 parts of anti-ultraviolet auxiliary agent, 750 parts of solvent, 10 parts of dispersant, 10 parts of defoaming agent, wherein, isocyanate is TDI; Hydroxyl polyether polyol is trihydroxy polyether polyol, molecular weight 1000, polyether for CASE purchased from Dow Chemical Company; silicone modified acrylate purchased from Dongguan Shanmu Technology New Material Company, model is 6730; catalyst is dibutyltin dilaurate; chain extender is trimethylol base propane; antioxidant is 2,6-di-tert-butyl-4-methylphenol; anti-ultraviolet additive is benzotriazole; solvent is a mixture of butanone, ethyl acetate and tetrahydrofuran (weight ratio of butanone: acetic acid Ethyl ester: te...

Embodiment 2

[0043]This embodiment provides a heat repair coating, which is prepared from the following raw materials in parts by weight: 287 parts of isocyanate, 192 parts of hydroxyl polyether polyol, 20 parts of silicone modified acrylate, 10 parts of catalyst, and chain extender 102 parts, 5 parts of antioxidant, 8 parts of anti-ultraviolet auxiliary agent, 750 parts of solvent, 10 parts of dispersant, 10 parts of defoamer, wherein, isocyanate is MDI; hydroxyl polyether polyol is trihydroxy polyether polyol, molecular weight 1000, purchased from the CASE polyether of Dow Chemical Company; Silicone modified acrylate was purchased from Dongguan Shanmu Science and Technology New Material Company, model is 6730; Catalyst is bismuth neodecanoate; Chain extender is trimethylol Propane; Antioxidant is 2,6-di-tert-butyl-4-methylphenol; Anti-ultraviolet auxiliary agent is benzophenone; Solvent is the mixture of butanone, ethyl acetate and tetrahydrofuran (weight ratio of butanone: ethyl acetate ...

Embodiment 3

[0051] This embodiment provides a heat repair coating, which is prepared from the following raw materials in parts by weight: 175 parts of isocyanate, 250 parts of hydroxyl polyether polyol, 20 parts of silicone modified acrylate, 20 parts of catalyst, and chain extender 90 parts, 8 parts of antioxidant, 5 parts of anti-ultraviolet auxiliary agent, 720 parts of solvent, 8 parts of dispersant, 10 parts of defoamer, wherein, isocyanate is HDI; hydroxyl polyether polyol is trihydroxy polyether polyol, molecular weight For 300, polyether was purchased from Dow Chemical Company's CASE; Silicone-modified acrylate was purchased from Dongguan Shanmu Science and Technology New Material Company, and the model was 6730; the catalyst was bismuth naphthenate; the chain extender was glycerol; The antioxidant is 3,5-di-tert-butyl-4-hydroxyphenyl tetraol ester; the anti-ultraviolet additive is 2-hydroxy-4-n-octyloxybenzophenone; the solvent is butanone, ethyl acetate and A mixture of tetrahyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com