Preparation method of cigarette tow containing composite phase change material

A technology of composite phase change materials and tows, applied in heat exchange materials, chemical instruments and methods, tobacco, etc., can solve the problems of lowering the quality of flue gas, complicated production process, and ineffective effects, etc., to reduce the temperature of flue gas , The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

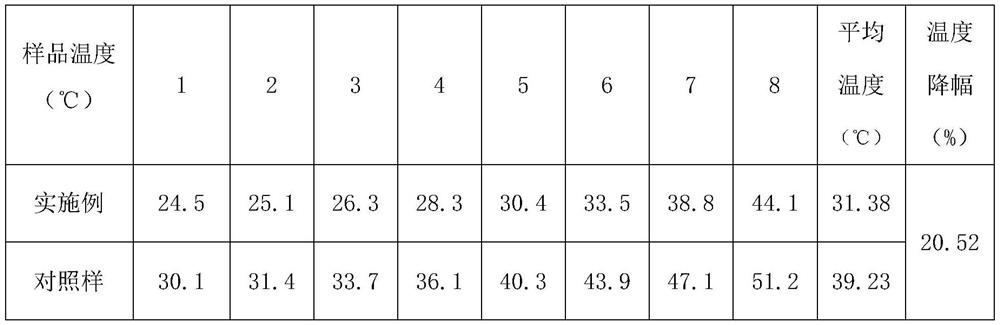

[0028] Mix polypropylene particles, whitening masterbatches, vinyl acetate and its copolymers, and composite phase-change materials uniformly in a mass ratio of 25:3:3:6, and put them into the spinning machine, wherein the composite phase-change materials are hydrated by crystallization The mass ratio of material and cooling particles is 5:100; the mass ratio of cooling particles is polylactic acid: glyceryl tristearate = 95:20. Heating at a temperature of 220°C, the melted mixed fluid is ejected through the spinneret at high speed by high-pressure airflow. After pre-stretching, it enters the alcohol washing and water washing pools, and then enters the crimping machine after washing. The number of crimps is set to 24 pieces / 25mm. Then enter the drying oven, the drying conditions are temperature 50±5°C, air pressure 0.45±0.05MPa, after drying, the fiber tow for cigarette filter containing the composite phase change material is obtained.

[0029] Obtain ordinary polypropylene f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com