Biological-photocatalytic combined treatment method for oil-containing waste residues

A technology of combined treatment and photocatalysis, applied in the removal of solid waste, etc., can solve the problems of poor degradation effect, long treatment period and complicated process, achieve excellent visible light catalysis effect, improve the reaction rate constant, and strengthen the photolysis reaction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

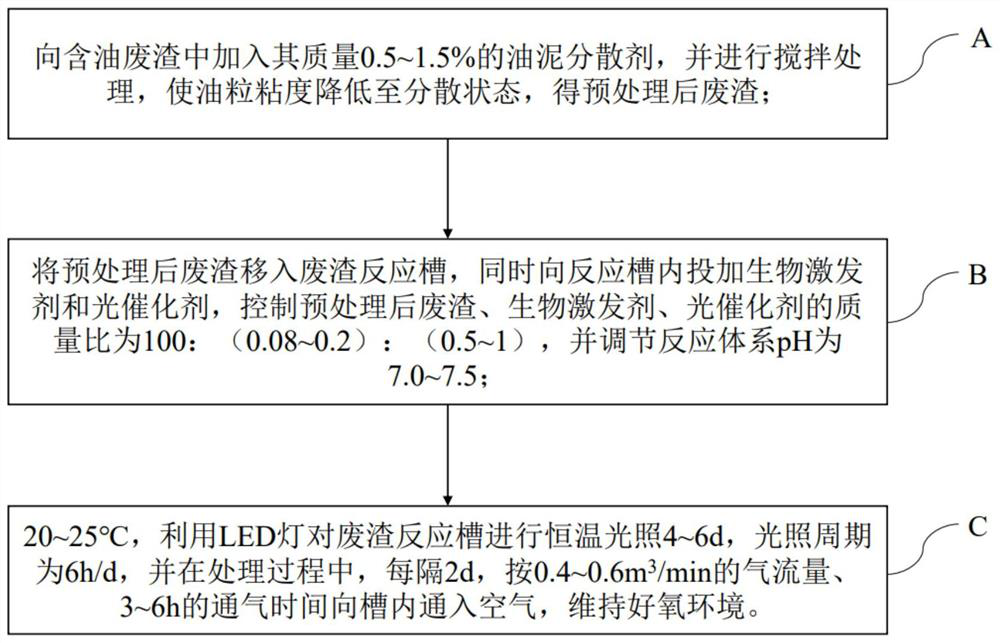

[0032] A biological-photocatalytic combined treatment method for oily waste residue, comprising the following steps:

[0033] A. Preparation:

[0034] A1: Preparation of oil sludge dispersant: mix nonionic surfactant, sodium silicate, and sodium sulfate uniformly in a mass ratio of 0.5:4.2:1.6;

[0035] A2: Preparation of petroleum hydrocarbon degrading bacterial agent: mix Pseudomonas, Achromobacter, and Acinetobacter in a mass ratio of 1:1.5:0.6;

[0036] A3: Preparation of phosphorus inorganic salt: mix monoammonium phosphate and diammonium phosphate in a mass ratio of 1:0.5;

[0037] A4: Preparation of nano CuS / α-Fe 2 o 3 Composite catalyst: Add nano-α-Fe to 0.1mol / L copper nitrate solution 2 o 3 , after ultrasonic dispersion, drop 0.1mol / L sodium sulfide solution to control the copper nitrate solution, sodium sulfide solution, nano-α-Fe 2 o 3 The dosage ratio is 50mL: 50mL: 1g, heat and reflux at 130°C for 3h, filter, wash, and dry to obtain nano-CuS / α-Fe 2 o 3 C...

Embodiment 2

[0042] A biological-photocatalytic combined treatment method for oily waste residue, comprising the following steps:

[0043] A. Preparation:

[0044] A1: Preparation of oil sludge dispersant: mix nonionic surfactant, sodium silicate, and sodium sulfate uniformly in a mass ratio of 1:4:1.3;

[0045] A2: Preparation of petroleum hydrocarbon degrading bacteria agent: mix Pseudomonas, Achromobacter, and Acinetobacter in a mass ratio of 1:1.8:0.9;

[0046] A3: Preparation of phosphorus inorganic salt: mix monoammonium phosphate and diammonium phosphate in a mass ratio of 1:0.75;

[0047] A4: Preparation of nano CuS / α-Fe 2 o 3 Composite catalyst: Add nano-α-Fe to 0.1mol / L copper nitrate solution 2 o 3 , after ultrasonic dispersion, drop 0.1mol / L sodium sulfide solution to control the copper nitrate solution, sodium sulfide solution, nano-α-Fe 2 o 3 The dosage ratio is 50mL: 50mL: 1g, heated and refluxed at 150°C for 5h, filtered, washed and dried to obtain nano-CuS / α-Fe 2 o...

Embodiment 3

[0052] A biological-photocatalytic combined treatment method for oily waste residue, comprising the following steps:

[0053] A. Preparation:

[0054] A1: Preparation of oil sludge dispersant: mix nonionic surfactant, sodium silicate, and sodium sulfate uniformly in a mass ratio of 1:4:1.3;

[0055] A2: Preparation of petroleum hydrocarbon degrading bacterial agent: mix Pseudomonas, Achromobacter, and Acinetobacter evenly in a mass ratio of 1:2:1.2;

[0056] A3: Preparation of phosphorus inorganic salt: mix monoammonium phosphate and diammonium phosphate in a mass ratio of 1:1;

[0057] A4: Preparation of nano CuS / α-Fe 2 o 3 Composite catalyst: Add nano-α-Fe to 0.1mol / L copper nitrate solution 2 o 3 , after ultrasonic dispersion, drop 0.1mol / L sodium sulfide solution to control the copper nitrate solution, sodium sulfide solution, nano-α-Fe 2 o 3 The dosage ratio is 50mL: 50mL: 1.2g, heat and reflux at 160°C for 6h, filter, wash, and dry to obtain nano-CuS / α-Fe 2 o 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com