Method for purifying byproduct sodium chloride in organic silicon high-salinity wastewater

A high-salt wastewater and organosilicon technology, applied in chemical instruments and methods, alkali metal chloride, alkali metal halide purification, etc., can solve the problems of complex pollutant composition, waste of salt resources, and high impurity content of sodium chloride, To achieve the effect of optimizing the purification and concentration process, speeding up the time and speed, and speeding up the amount of precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

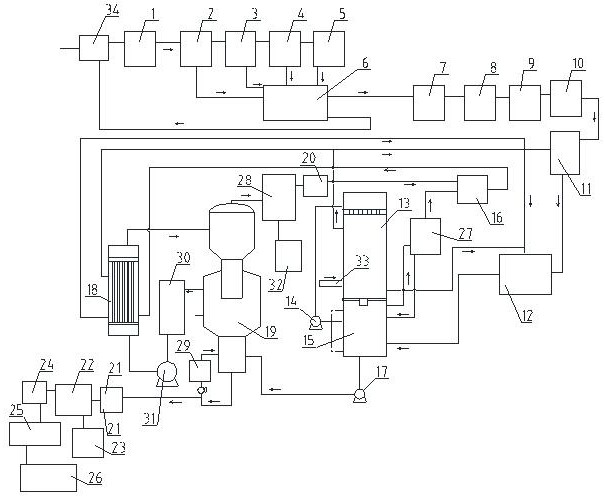

Image

Examples

Embodiment 1

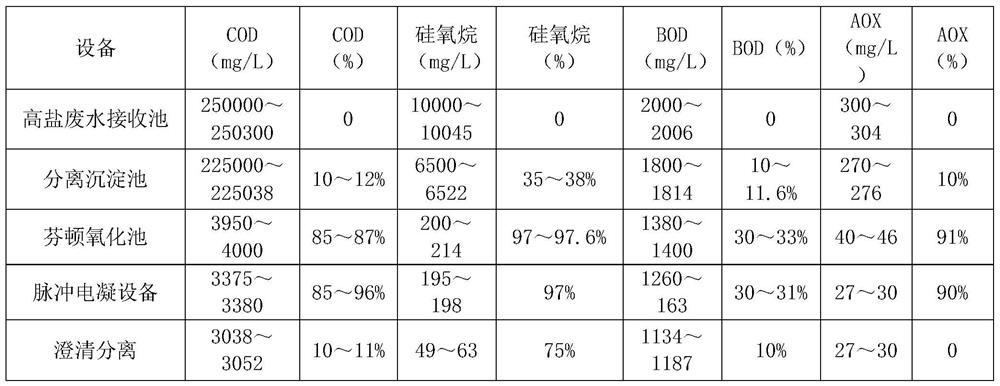

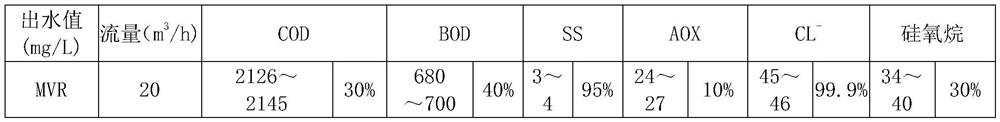

[0016] The method for purifying by-product sodium chloride in the organosilicon high-salt wastewater described in the present embodiment 1 includes a high-salt wastewater pretreatment stage and an MVR evaporation stage, as follows:

[0017] 1. The pretreatment stage of high-salt wastewater: first, the organosilicon high-salt wastewater stored in the wastewater receiving tank 34 is introduced into the separation and sedimentation tank 1, and after oil, water, and sediment are separated, the discharged high-salt wastewater enters successively to Fenton pool A2, Fenton pool B3, Fenton pool C4 and Fenton pool D5, and then according to the COD content of high-salt wastewater in each Fenton pool, add different amounts of Fenton adjustments to the corresponding Fenton pools The reaction process of organic silicon high-salt wastewater in Fenton pool A2, Fenton pool B3, Fenton pool C4 and Fenton pool D5 is: after organic silicon high-salt wastewater enters each Fenton pool, it needs to ...

Embodiment 2

[0027] The method for purifying by-product sodium chloride in the organosilicon high-salt wastewater described in the present embodiment 2 includes a high-salt wastewater pretreatment stage and an MVR evaporation stage, as follows:

[0028] 1. The pretreatment stage of high-salt wastewater: first, the organosilicon high-salt wastewater stored in the wastewater receiving tank 34 is introduced into the separation and sedimentation tank 1, and after oil, water, and sediment are separated, the discharged high-salt wastewater enters successively to Fenton pool A2, Fenton pool B3, Fenton pool C4 and Fenton pool D5, and then according to the COD content of high-salt wastewater in each Fenton pool, add different amounts of Fenton adjustments to the corresponding Fenton pools The reaction process of organic silicon high-salt wastewater in Fenton pool A2, Fenton pool B3, Fenton pool C4 and Fenton pool D5 is: after organic silicon high-salt wastewater enters each Fenton pool, it needs to ...

Embodiment 3

[0038] The method for purifying by-product sodium chloride in the organosilicon high-salt wastewater described in the present embodiment 3 includes a high-salt wastewater pretreatment stage and an MVR evaporation stage, as follows:

[0039] 1. The pretreatment stage of high-salt wastewater: first, the organosilicon high-salt wastewater stored in the wastewater receiving tank 34 is introduced into the separation and sedimentation tank 1, and after oil, water, and sediment are separated, the discharged high-salt wastewater enters successively to Fenton pool A2, Fenton pool B3, Fenton pool C4 and Fenton pool D5, and then according to the COD content of high-salt wastewater in each Fenton pool, add different amounts of Fenton adjustments to the corresponding Fenton pools The reaction process of organic silicon high-salt wastewater in Fenton pool A2, Fenton pool B3, Fenton pool C4 and Fenton pool D5 is: after organic silicon high-salt wastewater enters each Fenton pool, it needs to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com