Preparation method and application of carbon quantum dot/chitosan derivative hydrogel with light-stress dual response

A technology of chitosan derivatives and carbon quantum dots, applied in chemical instruments and methods, luminescent materials, nano optics, etc., can solve the problems of high mechanical mismatch, poor biocompatibility, and low conductivity, and achieve excellent Good mechanical properties, good electrical conductivity, and excellent optical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

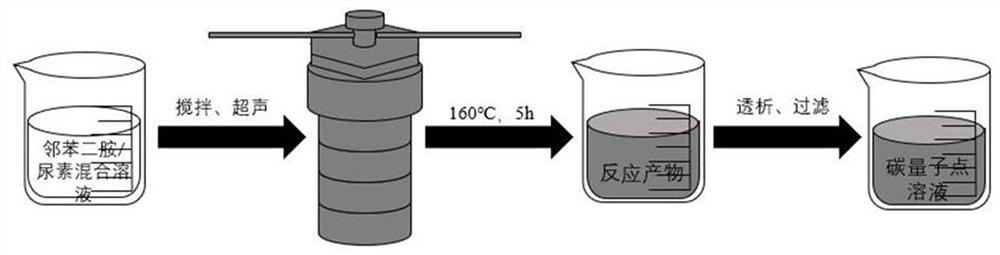

[0037] The invention provides a kind of preparation method of carbon quantum dot / chitosan derivative hydrogel, comprising the following steps:

[0038] (1) Preparation of carbon quantum dot solution

[0039] Mix o-phenylenediamine and urea in water evenly, heat at 160°C for 5 hours, and cool to room temperature to obtain a carbon quantum dot solution;

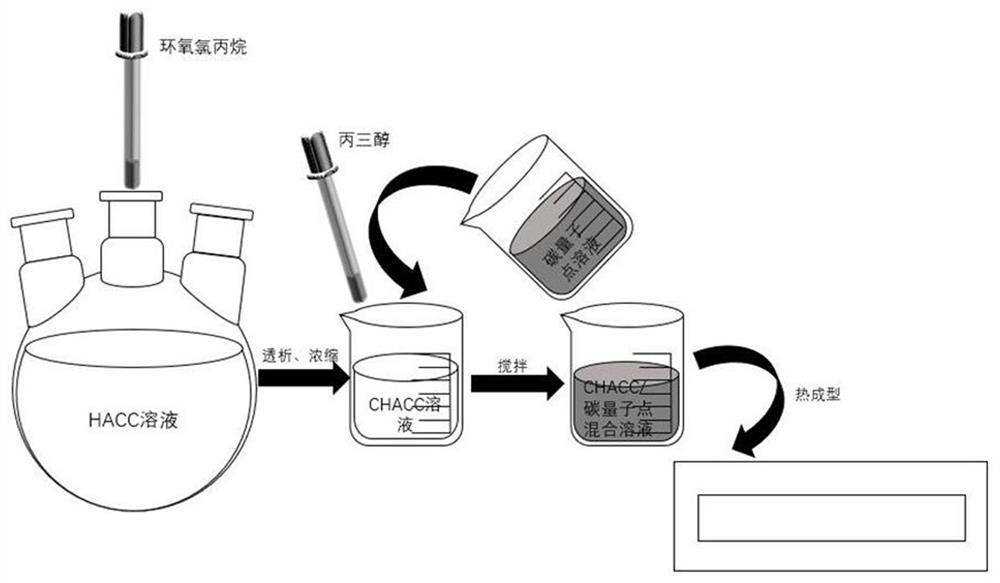

[0040] (2) Preparation of cross-linked chitosan quaternary ammonium salt solution

[0041] Drop the sodium hydroxide solution into the chitosan quaternary ammonium salt solution and keep stirring until the pH value reaches 10. When heated to 70°C, add the crosslinking agent epichlorohydrin to react, and continuously add the sodium hydroxide solution dropwise during the reaction Keeping the pH of the reaction system at 10, reacting at a constant temperature for 4 hours, cooling to room temperature naturally, adjusting the pH value to 7 with hydrochloric acid solution, adding glycerol to obtain a cross-linked chitosan quaternary...

Embodiment 1

[0058] The chemical substance materials used in this embodiment are: chitosan quaternary ammonium salt, epichlorohydrin, sodium hydroxide, hydrochloric acid, glycerol, o-phenylenediamine, urea, deionized water, and quality purity and precision control . The combined dosage is as follows: in grams, milliliters, millimeters, centimeters 3 is the unit of measurement. The chemical substances and materials used in other embodiments are the same as in this embodiment unless otherwise specified.

[0059] Chitosan quaternary ammonium salt: HACC solid solid 99.5% 2.0g±0.001g

[0060] Epichlorohydrin: C 3 h 5 ClO liquid liquid 99.5% 4mL±0.001mL

[0061] Sodium hydroxide: NaOH solid solid 99.5% 5g±0.001g

[0062] Hydrochloric acid: HCl liquid liquid 99.5% 23mL±0.001mL

[0063] Glycerol: C 3 h 8 o 3 Liquid liquid 99.5% 1mL±0.001mL

[0064] o-Phenylenediamine: C 6 h 8 N 2 Solid solid 98% 0.1g±0.001g

[0065] Urea: CH 4 N 2 O solid solid 99% 0.5g±0.001g

[0066] Deionize...

Embodiment 2

[0097] The preparation method of nitrogen-doped carbon quantum dot / chitosan derivative hydrogel comprises the following steps:

[0098] (1) Preparation of nitrogen-doped carbon quantum dots / cross-linked chitosan quaternary ammonium hydrogel precursor

[0099] Accurately weigh 0.1 g of o-phenylenediamine and 0.5 g of urea with an electronic balance, dissolve in 16 ml of deionized water, stir at 30°C for 20 min, and sonicate for 10 min. The system was transferred to a 100ml stainless steel autoclave lined with polytetrafluoroethylene, and heated at 160°C for 5h. After cooling to room temperature, take it out, put the obtained carbon quantum dot solution into a 500D dialysis bag, use deionized water as the medium for dialysis for 12 hours, and change the water every 2 hours. During the dialysis process, it can be clearly seen that the color of the dialysate prolongs with time Gradually changed from yellow to colorless, and the dialysate was colorless and transparent after 12 hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com