Flexible PPy/MXene-PDA photo-thermal fabric for solar evaporator and preparation method thereof

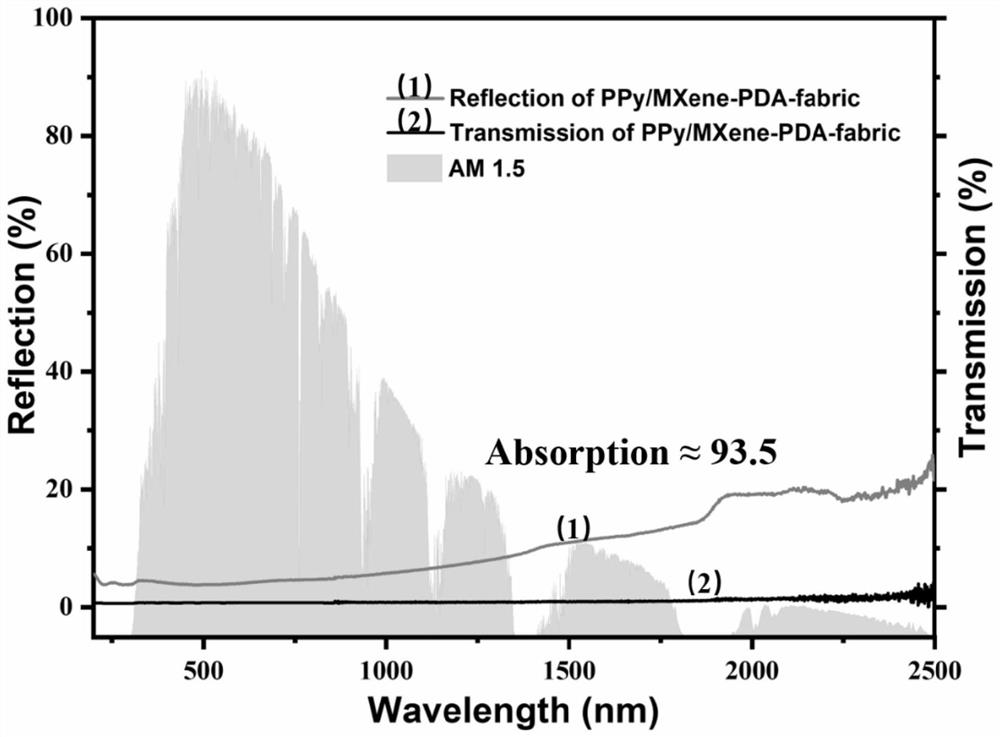

A technology of solar evaporators and fabrics, applied in the direction of steam generation methods, steam generation methods, chemical instruments and methods using solar energy, etc., can solve the problems of unstable photothermal performance, difficult transportation of photothermal materials, etc., and achieve good practicability and environmental applicability, excellent light-to-heat conversion performance, and easy transportation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

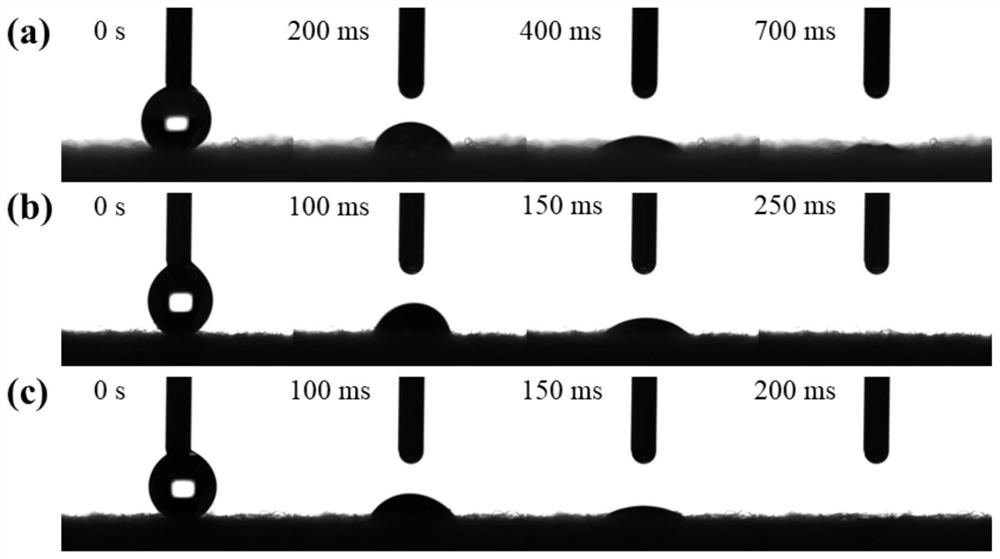

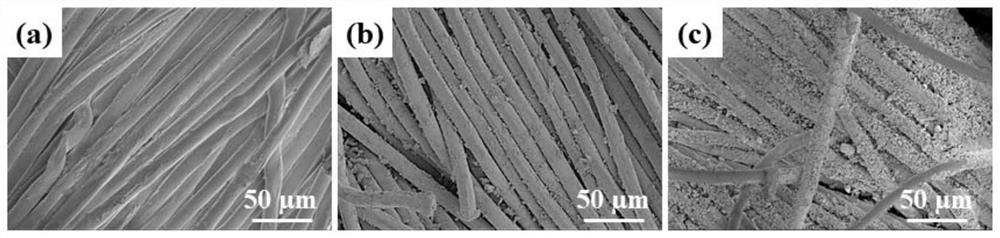

[0032] The invention provides a method for preparing a flexible polypyrrole / MXene-dopamine (PPy / MXene-PDA) photothermal fabric for a solar evaporator, comprising the following steps:

[0033] Step 1: Put Ti 3 AlC 2Add the powder into the hydrofluoric acid solution and keep stirring at a constant temperature. After the stirring is completed, perform ultrasonic stripping and high-speed centrifugal cleaning several times until the pH value of the supernatant is 5.5-6.5. After the sediment is vacuum-dried, it is ground and sieved to obtain Ti 3 C 2 MXene powder.

[0034] Wherein, the concentration of hydrofluoric acid is 36%-40%, the stirring temperature is 30-40°C, the stirring time is 24-48h, and the vacuum drying temperature is 50-70°C.

[0035] Step 2: Cut the commodity polyester fiber fabric into required size (such as a circle with a diameter of 4cm), carry out ultrasonic cleaning (20-40min each time) for 2-4 times in absolute ethanol or acetone solution, and then Take o...

Embodiment 1

[0042] Step 1: Put Ti 3 AlC 2 Add the powder into the hydrofluoric acid solution and keep stirring at a constant temperature. After the stirring is completed, perform ultrasonic stripping and high-speed centrifugal cleaning several times until the pH value of the supernatant is 6. After the sediment is vacuum-dried, it is ground and sieved to obtain Ti 3 C 2 MXene powder.

[0043] Wherein, the concentration of hydrofluoric acid is 36%, the stirring temperature is 30°C, the stirring time is 24h, and the vacuum drying temperature is 50°C.

[0044] Step 2: Cut the commercial polyester fabric into the required size (for example, a circle with a diameter of 4cm), perform ultrasonic cleaning twice in absolute ethanol or acetone solution (20min each time), and then take it out and dry it. A clean polyester fiber fabric is obtained.

[0045] Step 3: adding the washed polyester fiber fabric to the weakly alkaline dopamine hydrochloride solution, stirring continuously at room temper...

Embodiment 2

[0051] Step 1: Put Ti 3 AlC 2 Add the powder into the hydrofluoric acid solution and keep stirring at a constant temperature. After the stirring is completed, perform ultrasonic stripping and high-speed centrifugal cleaning several times until the pH value of the supernatant is 5.5. After the sediment is vacuum-dried, it is ground and sieved to obtain Ti 3 C 2 MXene powder.

[0052] Wherein, the concentration of hydrofluoric acid is 40%, the stirring temperature is 40°C, the stirring time is 48h, and the vacuum drying temperature is 70°C.

[0053] Step 2: Cut the commercial polyester fiber fabric into the required size (for example, a circle with a diameter of 4cm), perform 4 times of ultrasonic cleaning in absolute ethanol or acetone solution (each 40min), and then take it out and dry it. A clean polyester fiber fabric is obtained.

[0054] Step 3: adding the washed polyester fiber fabric to the weakly alkaline dopamine hydrochloride solution, stirring continuously at roo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com