Liquid calcium fertilizer as well as preparation method and application thereof

A liquid calcium and calcium element technology, applied in liquid fertilizer, application, calcium fertilizer and other directions, can solve the problems of low calcium content and instability in liquid calcium fertilizer, and achieve the effect of rich source, easy absorption and improved utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

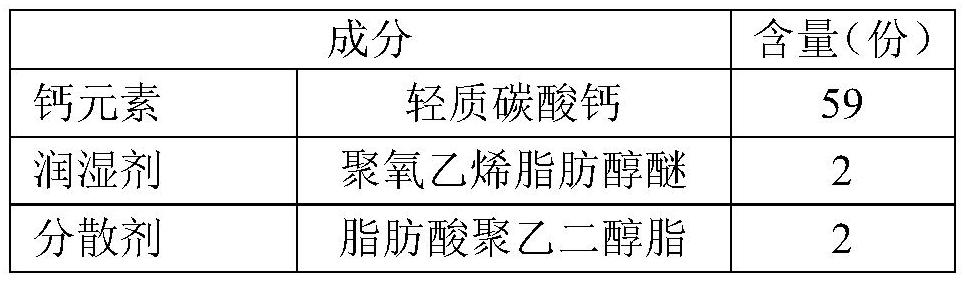

[0075] Embodiment 1 liquid calcium fertilizer

[0076] 1. A liquid calcium fertilizer

[0077] Prepare liquid fertilizer according to each component of following parts by weight:

[0078]

[0079]

[0080] 2. Preparation method

[0081] S1. Add 1 / 3 of water into the high-shear reactor a, adjust the speed to 300r / min, add weighed calcium element light calcium carbonate in turn, cut for 30min, and stir evenly to obtain liquid A;

[0082] S2. Add the remaining 2 / 3 of the water into the high-shear reactor b, adjust the speed to 200r / min, and then add the wetting agent sodium alkyl sulfate, the dispersant fatty alcohol polyoxyethylene ether, and the surfactant ten Sodium dialkylbenzenesulfonate, emulsifier gum arabic, antifreeze agent propylene glycol, thickener fenugreek gum, shear for 20min, stir to obtain B liquid;

[0083] S3. Adjust the speed of the high-shear reactor a to 1500r / min, and the reaction temperature is 55°C to 65°C. Slowly add liquid B into the high-shear...

Embodiment 2

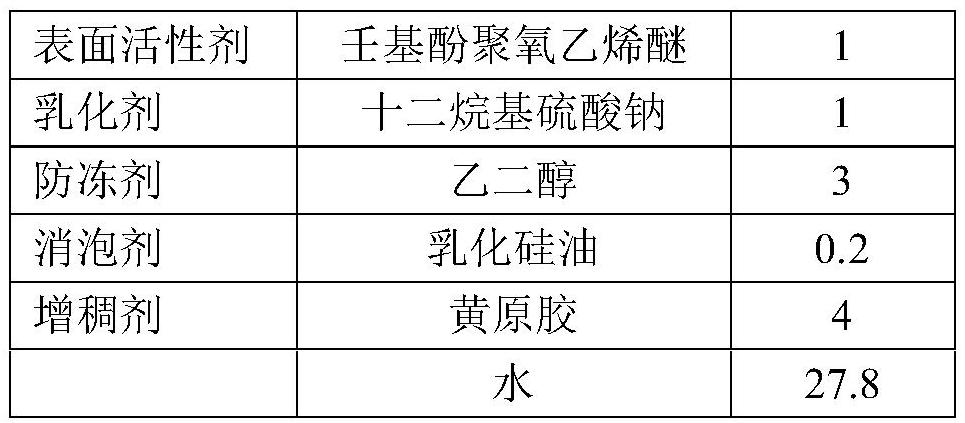

[0086] The liquid calcium fertilizer prepared by embodiment 2 different components

[0087] 1. Liquid calcium fertilizer

[0088] The components for preparing the fertilizer are shown in Table 1, and the parts by weight of each component are the same as in Example 1. 5 parts of calcium oxide and 54 parts of light calcium carbonate in No. 2 calcium element, 5 parts of calcium hydroxide and 54 parts of light calcium carbonate in No. 3 calcium element.

[0089] Table 1

[0090]

[0091]

[0092]

[0093] 2. The preparation method is the same as in Example 1.

Embodiment 3

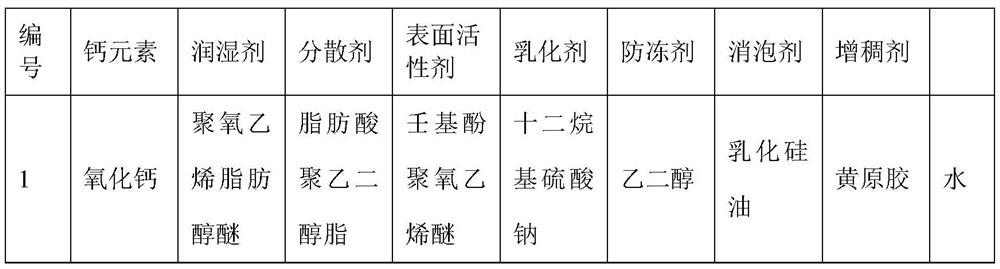

[0094] The liquid calcium fertilizer prepared by the components of embodiment 3 different contents

[0095] 1. Liquid calcium fertilizer

[0096] The content (parts by weight) information of each component of the prepared fertilizer is shown in Table 2, and each component is the same as in Example 1.

[0097] Table 2 Different contents of liquid calcium fertilizer (parts by weight)

[0098]

[0099] 2. The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com