Photo-thermal conversion eutectic material containing pyrene and preparation method of material

A technology for photothermal conversion and eutectic materials, applied in organic chemistry, crystallization purification/separation, carboxylic acid nitrile purification/separation, etc., can solve the problem of low photothermal conversion efficiency, and achieve excellent photothermal conversion performance, repeatability The effect of high utilization rate and high photothermal conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

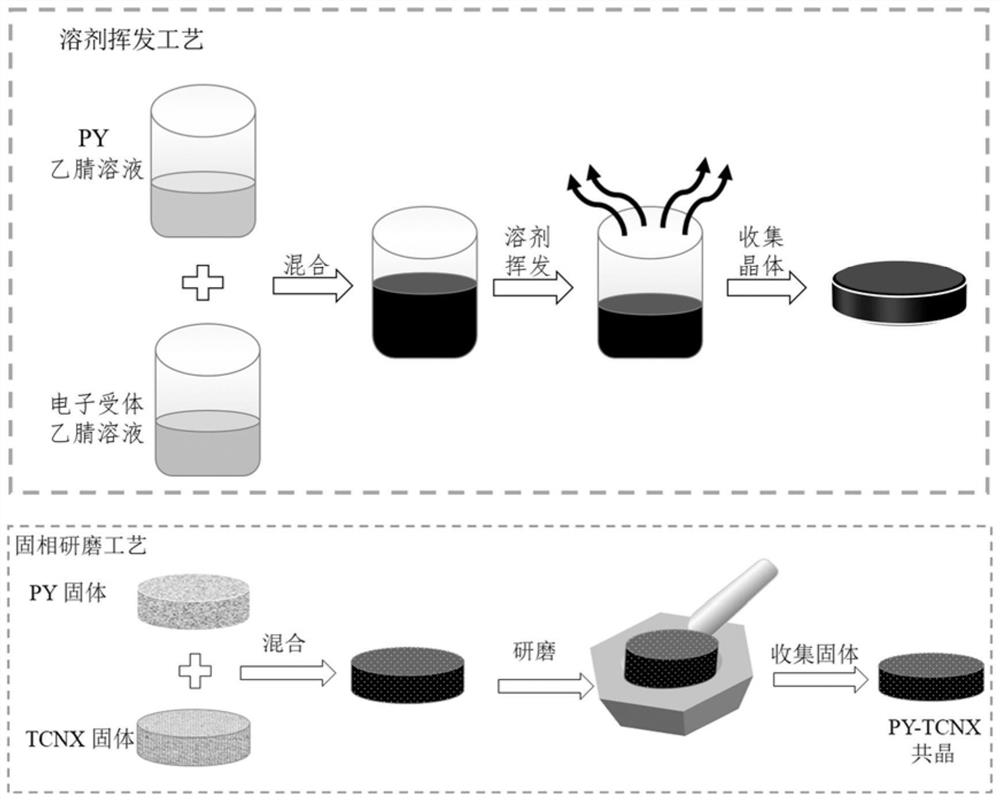

[0069] Such as figure 1 As shown, this embodiment adopts the solvent volatilization process route, and the detailed steps for preparing the photothermal conversion eutectic material containing PY by the solvent volatilization process route are as follows:

[0070] (1) Weigh 6.06 mg of PY solid and place it in a beaker, add 3 mL of ethyl acetate, and sonicate at room temperature for about 5 minutes to fully dissolve PY.

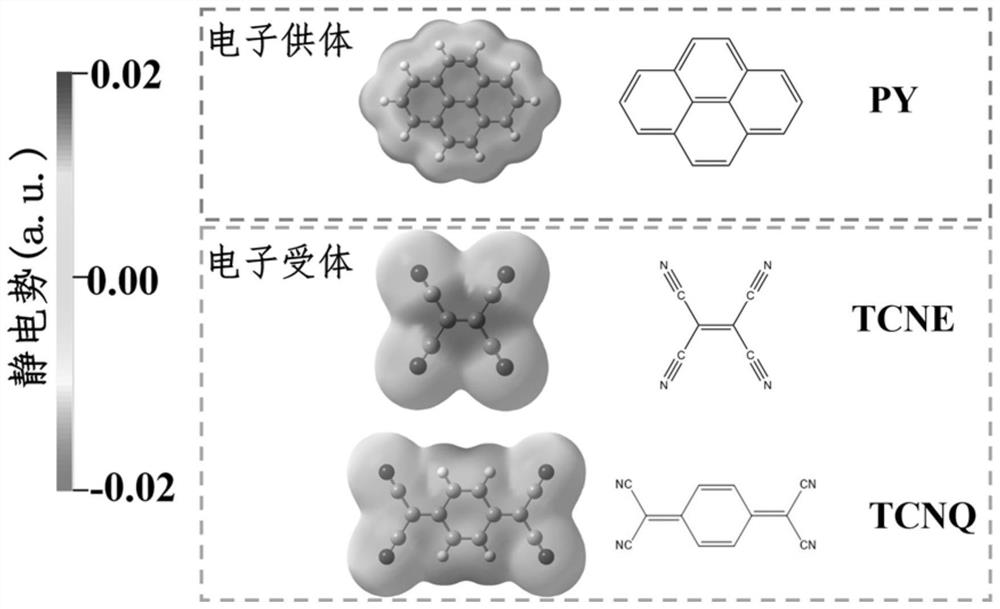

[0071] (2) Weigh 3.84mg solid electron acceptor component TCNE into a beaker, add 3mL ethyl acetate, and ultrasonicate at room temperature for 5 minutes to fully dissolve TCNE.

[0072] (3) The ethyl acetate solution of PY and the electron acceptor component is fully mixed to form a black intermolecular charge transfer complex.

[0073] (4) Seal the mouth of the beaker with a parafilm, and then punch a series of uniform small holes on the parafilm with the needle of a 1ml syringe. Finally, stand and volatilize under normal temperature and pressure, and the f...

Embodiment 2

[0075] Such as figure 1 As shown, this embodiment adopts the solvent volatilization process route, and the detailed steps for preparing the photothermal conversion eutectic material containing PY by the solvent volatilization process route are as follows:

[0076] (1) Weigh 6.06 mg of PY solid and place it in a beaker, add 3 mL of acetonitrile, and sonicate at room temperature for about 5 minutes to fully dissolve PY.

[0077] (2) Weigh 6.12 mg solid electron acceptor component TCNQ into a beaker, add 3 mL of acetonitrile, and ultrasonicate at room temperature for 5 minutes to fully dissolve TCNQ.

[0078] (3) The acetonitrile solution of PY and the electron acceptor component was fully mixed to form a black intermolecular charge transfer complex.

[0079] (4) Seal the mouth of the beaker with a parafilm, and then punch a series of uniform small holes on the parafilm with the needle of a 1ml syringe. Finally, stand and volatilize under normal temperature and pressure, and th...

Embodiment 3

[0081] Such as figure 1 As shown, this embodiment adopts the solid phase grinding method route and the solvent volatilization process route to prepare the photothermal conversion eutectic material containing PY. The detailed steps are as follows:

[0082] (1) Weigh 6.06 mg of electron donor component PY solid.

[0083] (2) Weigh the electron acceptor component, 3.84 mg of TCNE.

[0084] (3) The PY and the electron acceptor component solids are fully mixed, and the PY and the electron acceptor component in contact with each other begin to form a dark intermolecular CT complex.

[0085] (4) Transfer the solid mixture described in (3) to a mortar or ball mill, and pressurize and grind for 10 minutes. During this period, the contact between the two components is more sufficient, and the CT complex is promoted to form with the lowest energy. orderly self-assembly to form a cocrystal.

[0086] (5) After grinding, the eutectic material in the form of eutectic pyrene-tetracyanoethy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com