Preparation method of 2-(2-(2-aminoethoxy) ethoxy) acetic acid

A technology of aminoethoxy and ethoxy, which is applied in the field of preparation of 2-ethoxy)acetic acid, can solve the problems of many reaction by-products, combustion and explosion, and is not suitable for industrial scale-up production, and achieves product yield and High purity, mild reaction conditions, safe and controllable reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

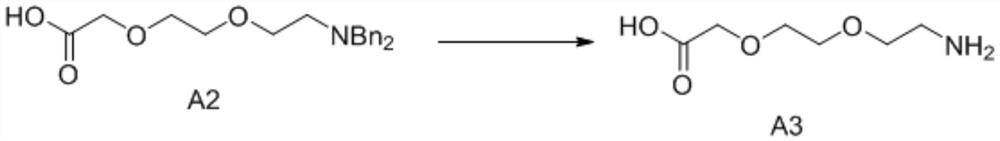

[0033] Embodiment 1: the preparation method of 2-(2-(2-aminoethoxy) ethoxy) acetic acid

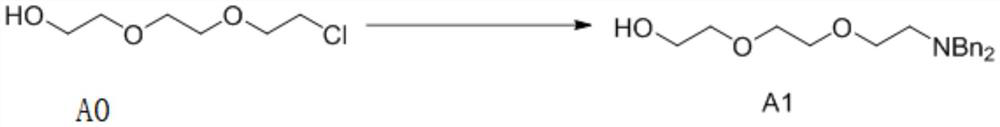

[0034] Prepare 2-(2-(2-aminoethoxy)ethoxy)acetic acid (ie Fmoc-AEEA) according to the following synthetic route:

[0035]

[0036] Step 1: Synthesis of Compound A1

[0037] Add 2-[2-(2-chloroethoxy)ethoxy]ethanol (i.e. compound A0, 843mg, 5.0mmol) in a round bottom flask, K 2 CO 3 (760mg, 5.5mmol) and NaBr (51.4mg, 0.5mmol); then add acetonitrile (13ml) and dibenzylamine (ie Bn 2 NH, 986mg, 5.0mmol), stirred at 80°C for 24 hours. After cooling to room temperature and filtering, the filtrate was evaporated to dryness to obtain 1.45 g of compound A1 with a yield of 88% and a purity of 90%.

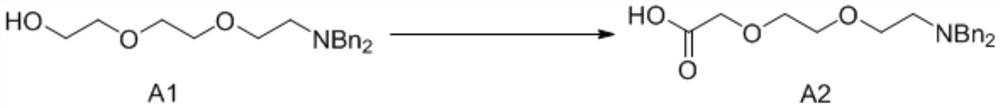

[0038] Step 2: Synthesis of Compound A2

[0039] Add compound A1 (1.32 g, 4 mmol) in 40 mL of acetone solution in 15 mL of saturated sodium bicarbonate solution, cool down to 0-5 °C with an ice bath, add NaBr (0.1 g, 1 mmol), TEMPO (ie 2, 2, 6 , 6-tetramethylpiperidine oxide, 0.015g, 0.1mmol), ...

Embodiment 2

[0045]Embodiment 2: the preparation method of 2-(2-(2-aminoethoxy) ethoxy) acetic acid

[0046] Synthesize Fmoc-AEEA according to the route of Example 1, the only difference is that the operation of the first step to synthesize compound A1 is:

[0047] Add 2-[2-(2-chloroethoxy)ethoxy]ethanol (i.e. compound A0, 337mg, 2.0mmol) in a round bottom flask, K 2 CO 3 (414.6mg, 3mmol) and NaBr (30.8mg, 0.3mmol); add acetonitrile (6ml) and dibenzylamine (473.5mg, 2.4mmol) and stir at 50°C for 24 hours. After cooling to room temperature and filtering, the filtrate was evaporated to dryness to obtain 0.5 g of compound A1 with a yield of 75% and a purity of 95%.

[0048] The purity of Fmoc-AEEA synthesized in this example is 99.8%, and the total yield is 75%×91%×93%×91%=57.76%.

Embodiment 3

[0049] Embodiment 3: the preparation method of 2-(2-(2-aminoethoxy) ethoxy) acetic acid

[0050] Synthesize Fmoc-AEEA according to the route of Example 1, the only difference is that the operation of the second step to synthesize compound A2 is:

[0051] Add compound A1 (0.66g, 2mmol) in 20mL acetone solution in 15mL saturated sodium bicarbonate solution, cool down to 0~5℃ with ice bath, add NaBr (0.1g, 1mmol), TEMPO (ie 2,2,6 , 6-tetramethylpiperidine oxide, 0.015g, 0.1mmol), then TCCA (i.e. trichloroisocyanuric acid, 1.87g, 8.0mmol) was added in batches, keeping the temperature of the system at 0-5°C, and the addition was completed Then the system was stirred at room temperature for 3 hours. After the reaction was completed, isopropanol was added and stirred for 30 minutes to quench the reaction. The reaction solution was filtered through diatomaceous earth and concentrated, then added 15 mL of saturated sodium carbonate solution, and extracted twice with 30 mL of ethyl ace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com