Preparation method of Ethyl silicate hydrolysis catalyst and ethyl silicate hydrolysate

A technology of hydrolysis catalyst and ethyl silicate, which is applied in the direction of chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., which can solve the problems of cracking of prepared materials and achieve stable reaction , easy to control, fast drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

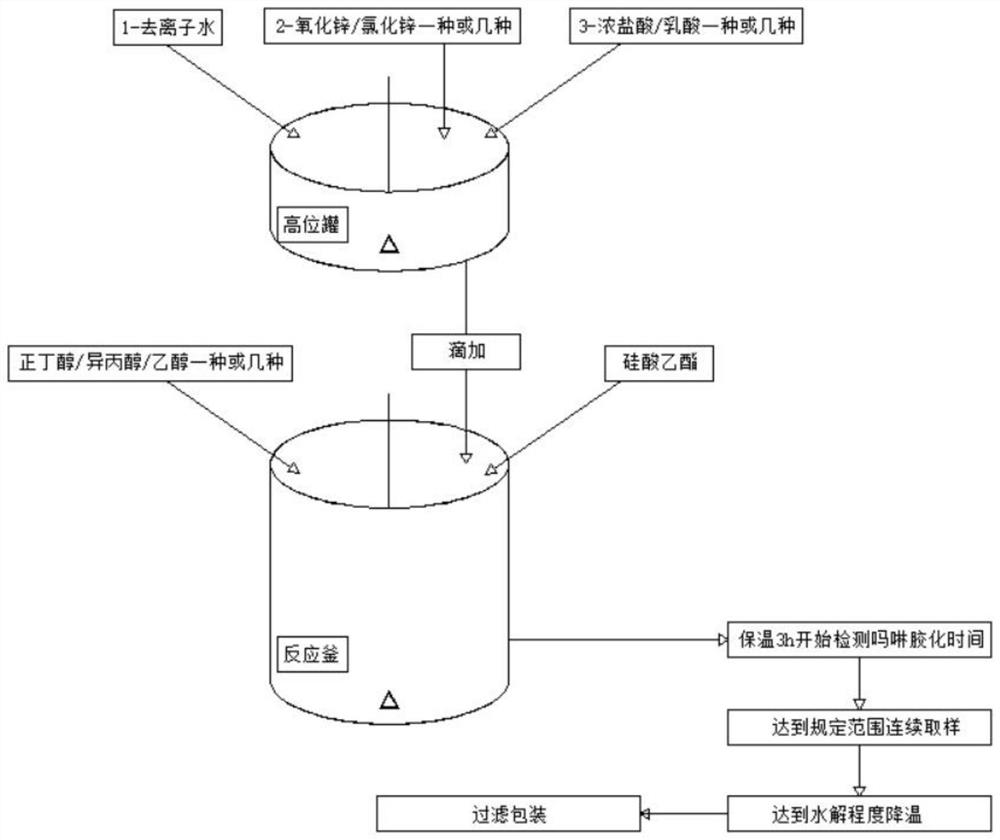

[0034] A method of preparing a hydrochloric acid hydrolyzate comprising catalyst configuration, catalyst drop, system holding, hydrolysis control, the preparation process is as follows:

[0035] In the clean high tank, deionized water is first put, then slowly put the zinc inorganic material and mixed acid components in the stirring state, stir evenly to cool to normal temperature, stop stirring spare, and complete the catalyst configuration;

[0036] The polyol (one or several of industrial n-butanol / isopropanol / ethanol) and orthodoxate is sequentially inserted in the clean lower reaction kettle, and the mixing is stirred to stir well, and the reaction is blended

[0037] The low-speed mixed state of the reactant retains the low speed agitation, slightly opens the high canopy of the valve so that the catalyst is slowly added to the lower reaction kettle and the reaction mixture, thereby achieving the catalyst drop, usually dropped within 2-3 hours. After completion, the dripp...

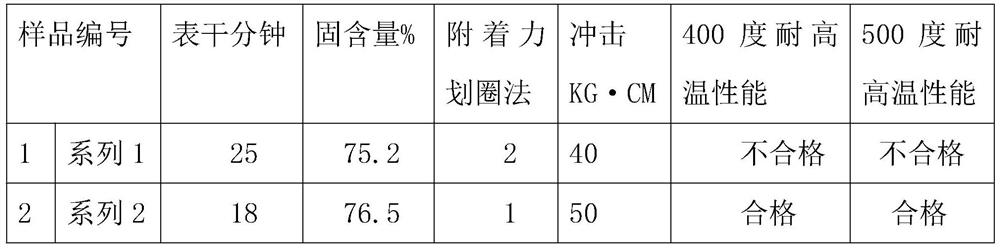

Embodiment 1

[0047] Ethyl silicate hydrolysis catalyst, whose composition ingredient is: 0.3% deionized water, 0.3% lactic acid, 1.3% concentrated hydrochloride; zinc oxide; zinc chloride; 1.52%;

[0048] Ethyl silicate hydrolyzate, its composition ingredient is by weight of 55%, ethanol 10%, n-butanol 15%, isopropanol 12%, and 8%.

Embodiment 2

[0050]Ethyl silicate hydrolysis catalyst, composition ingredients of 97% by weight of deionized water, 0.2% lactic acid 0.5%, concentrated hydrochloride; zinc oxide 1%; zinc chloride 1.3%;

[0051] Ethyl silicate hydrolyzate, its composition ingredient is by weight of 45%, ethanol 7%, n-butanol 18%, isopropanol 18%, and a catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com