Polyether modified organosilicon polymer and preparation method and application thereof

A polyether modification, silicone technology, applied in the direction of polyether adhesives, adhesive types, adhesives, etc., can solve the problems of high chloride ion content, poor temperature resistance, and many by-products, and achieve high yields , Improve heat resistance and tensile properties, the effect of mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

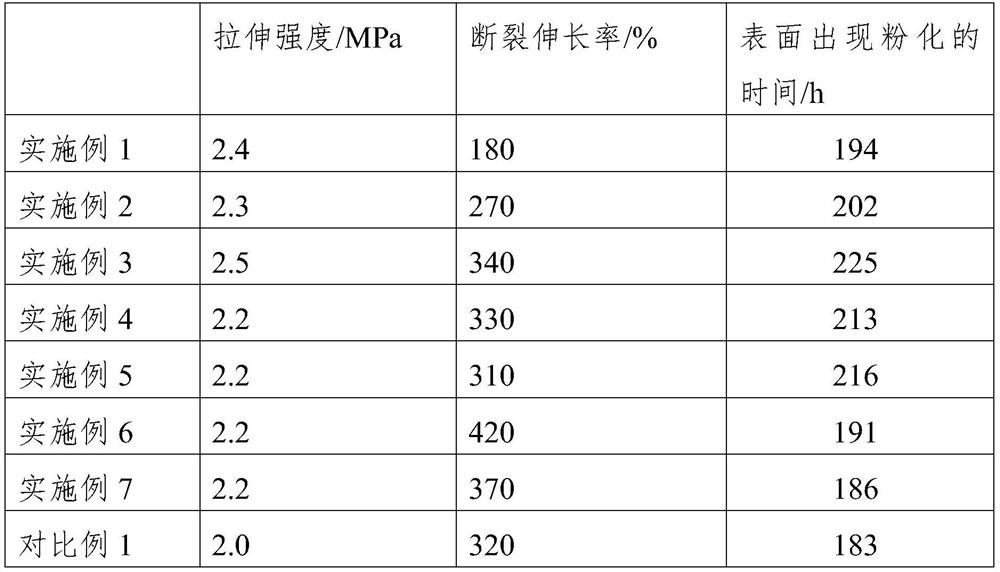

Examples

Embodiment 1

[0026] The embodiment of the present invention provides the preparation and application of a polyether modified silicone polymer, comprising the following steps:

[0027] 1) A-PPG-[Si(CH 3 ) 2 Synthesis of O]-PPG-A

[0028] Under the protection of nitrogen, 10g hydrogen-containing double-capped head and the first Pt catalyst (the consumption of the first Pt catalyst makes the Pt consumption in the reaction system be step 1) 20ppm of the total amount of reaction raw materials) and auxiliary agent A boron trifluoride diethyl ether (The molar ratio of boron trifluoride diethyl ether to the molar ratio of Pt in the first Pt catalyst is 1.5:1) Activated at 20°C for 1.5h, added dropwise 73.5g of double-end allyl-terminated polypropylene glycol, and added it to Heat the reaction at about 70°C for 3 hours, cool down, remove excess hydrogen-containing double-heads and other impurities, and obtain A-PPG-[Si(CH 3 ) 2 O]-PPG-A, the test iodine value is 47.3.

[0029] Wherein, the fir...

Embodiment 2

[0033] The method provided in this example is the same as that in Example 1, the only difference is that the double-terminal hydrogen-containing silane compound in the present invention is terminal hydrogen-containing silicone oil with a hydrogen content of 0.17-0.19%.

Embodiment 3

[0035] The method provided in this example is the same as that in Example 1, the only difference being that the double-terminal hydrogen-containing silane compound in the present invention is a terminal hydrogen-containing silicone oil with a hydrogen content of 0.11-0.13%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com