Aluminum alloy, and casting and preparation method thereof

An aluminum alloy casting and aluminum alloy technology, applied in the field of aluminum alloy materials, can solve the problems of corrosion resistance, mold non-adhesion, etc., and achieve the effects of excellent fluidity, grain refinement, and excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0066] An embodiment of the present invention also provides a preparation method of the above-mentioned aluminum alloy. The preparation method comprises the following steps S10-S20:

[0067] Step S10: providing raw materials according to the aluminum alloy to be prepared.

[0068] In some of these embodiments, the raw material can be composed of aluminum ingot, aluminum silicon, aluminum magnesium, aluminum iron, aluminum manganese, aluminum rare earth, aluminum titanium master alloy; but not limited thereto, as long as the raw material can meet the element composition requirements.

[0069] Step S20: After the raw materials are smelted, casting is performed.

[0070] In some embodiments, casting methods include but are not limited to die casting, squeeze casting, low pressure casting, gravity casting, differential pressure casting, vacuum die casting, and semi-solid casting.

[0071] In some of these embodiments, the step of casting is formed in a casting mold.

[0072] Th...

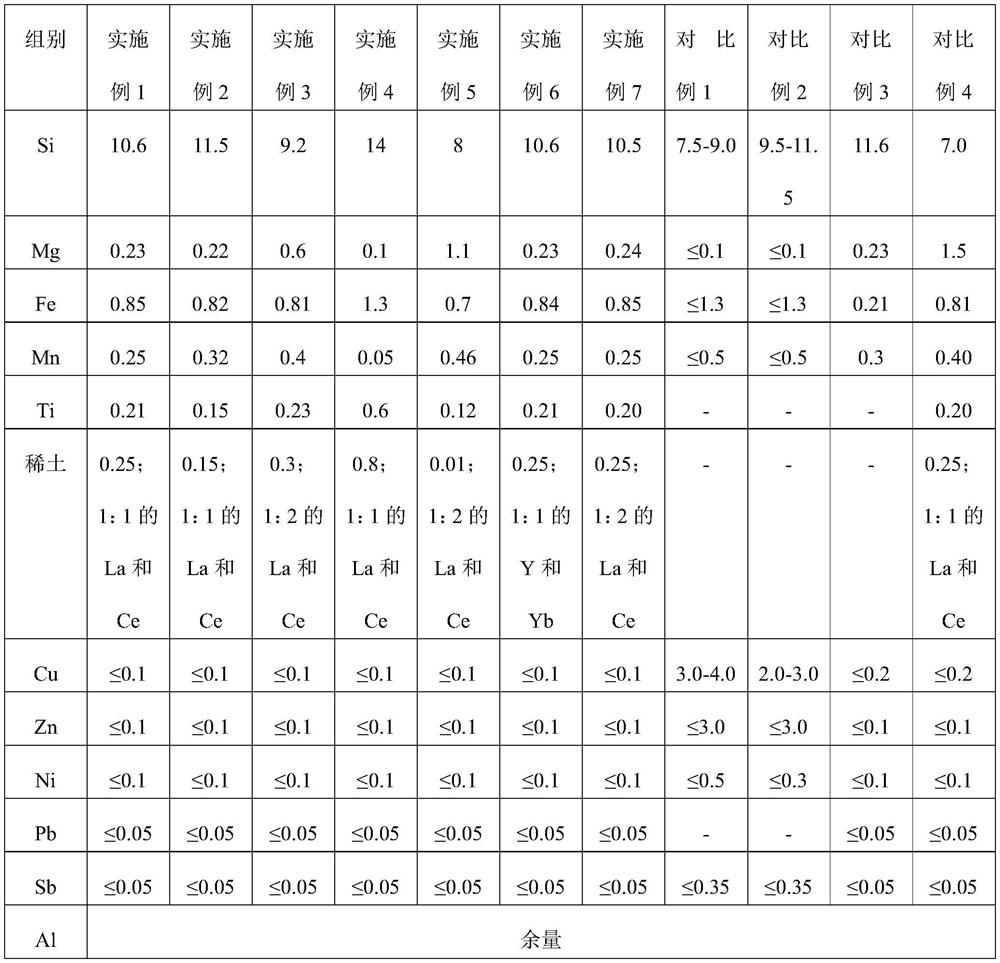

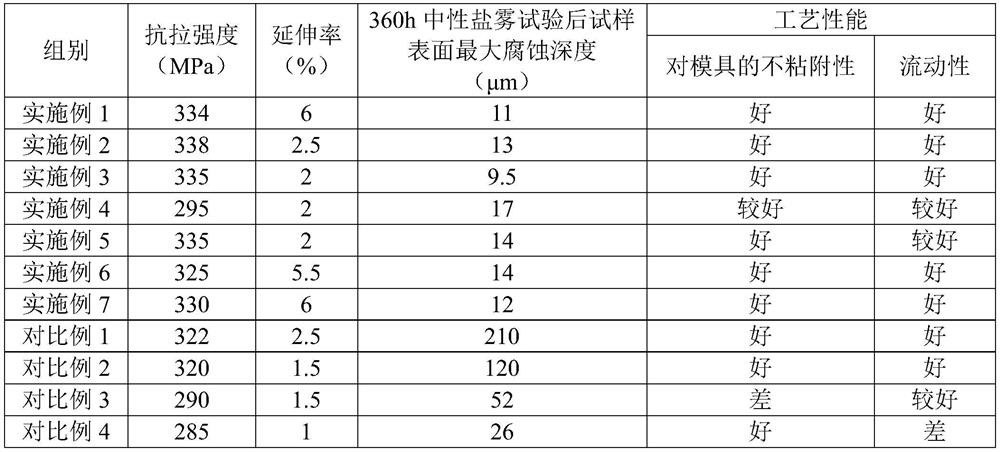

Embodiment 1

[0076] An aluminum alloy comprises the following components by weight percentage: 10.6% silicon; 0.23% magnesium; 0.85% iron; 0.25% manganese; 0.21% titanium; Accounting for 50%; copper ≤ 0.1%; zinc ≤ 0.1%; nickel ≤ 0.1%; lead ≤ 0.05%; tin ≤ 0.05%;

[0077] According to the above-mentioned composition ratio, add aluminum ingots into the smelting furnace, after the aluminum ingots are melted, add aluminum-silicon, aluminum-magnesium, aluminum-iron, aluminum-manganese, aluminum-titanium, and aluminum-rare-earth master alloys for melting, then refining and degassing treatment, and then After the composition is tested and qualified, the liquid aluminum is extruded into the product mold by a squeeze casting machine to prepare aluminum-silicon alloy castings.

Embodiment 2

[0079] An aluminum alloy comprises the following components by weight percentage: 11.5% silicon; 0.22% magnesium; 0.82% iron; 0.32% manganese; 0.15% titanium; Accounting for 50%; copper ≤ 0.1%; zinc ≤ 0.1%; nickel ≤ 0.1%; lead ≤ 0.05%; tin ≤ 0.05%;

[0080] According to the above-mentioned composition ratio, add aluminum ingots into the smelting furnace, after the aluminum ingots are melted, add aluminum-silicon, aluminum-magnesium, aluminum-iron, aluminum-manganese, aluminum-titanium, and aluminum-rare-earth master alloys for melting, then refining and degassing treatment, and then After the composition is tested and qualified, the liquid aluminum is extruded into the product mold by a high-pressure casting machine to prepare aluminum-silicon alloy castings.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com