Large-mode-field single-mode radiation-resistant erbium-ytterbium co-doped optical fiber and preparation method thereof

A radiation-resistant, large-mode-field technology, applied in cladding optical fiber, glass manufacturing equipment, glass fiber products, etc., can solve the problems of performance degradation and failure of erbium-ytterbium co-doped optical fiber, and improve the stability of radiation-resistant reinforcement , large mode field area, and the effect of reducing the refractive index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

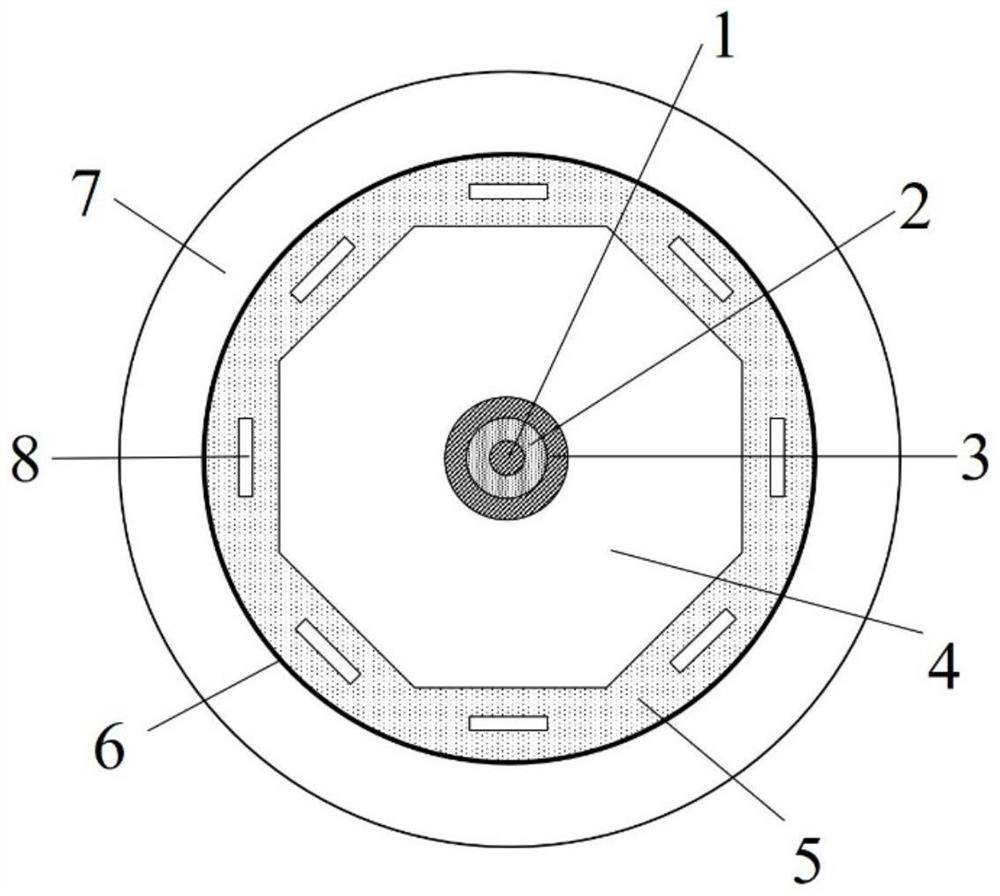

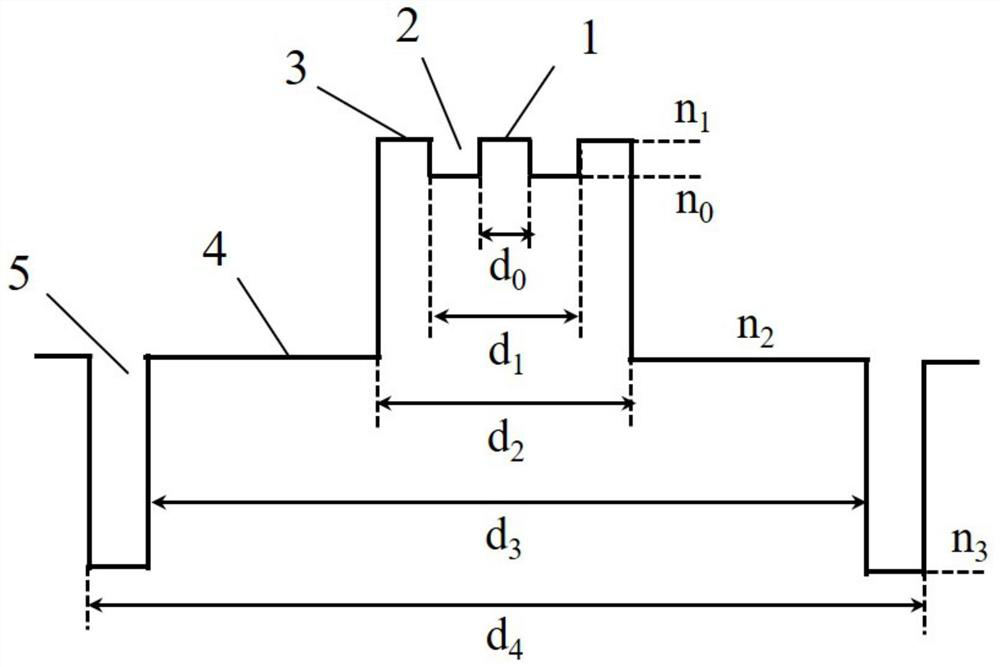

[0046] The preparation method of the large-mode-field single-mode radiation-resistant erbium-ytterbium co-doped optical fiber comprises the following steps:

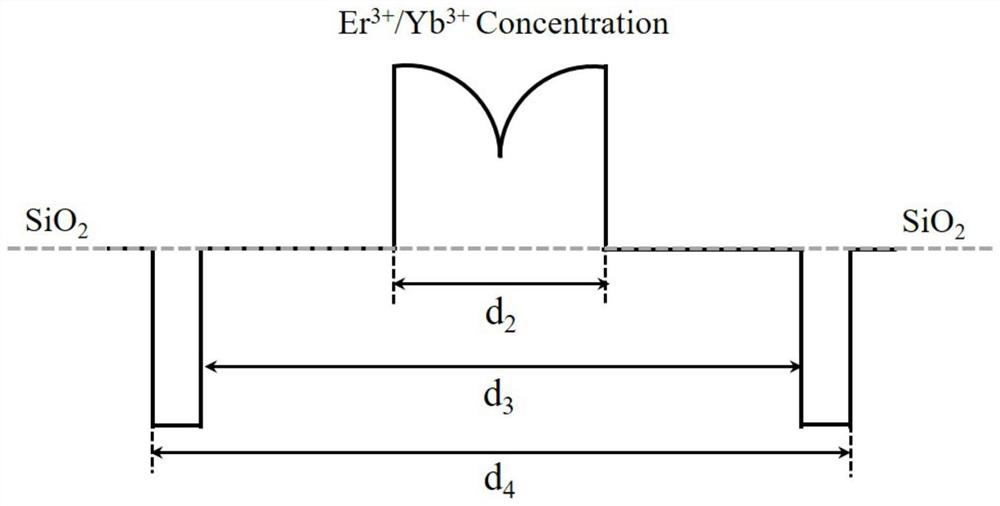

[0047] Step 1), using a quartz tube as a deposition liner, wherein the thickness of the quartz deposition tube is 0.5-1.0mm, using MCVD combined with chelate vapor deposition method to prepare the fiber core, after preheating and impurity removal treatment, according to the flow rate of the core components Design and set the flow rate of reaction materials and oxygen. The deposition temperature is 1600-1900°C. The ring outer core layer 3, the annular sunken core layer 2, and the center core layer 1 are deposited in sequence, and a solid core rod is shrunk by a single shrinkage process. Among them, the hydrogen flow rate is 90-120 sccm;

[0048] Step 2), according to the requirements of the fiber core cladding ratio, use the casing process to coat the quartz tube on the core rod, form the inner cladding 4 on the outer lay...

Embodiment

[0060] The preparation method of the erbium-ytterbium co-doped optical fiber preform is the same as the comparative example, the deposition liner adopts a 28 / 26mm quartz tube (28mm is the outer diameter of the quartz deposition tube, and 26mm is the inner diameter of the quartz deposition tube), and the reaction materials are respectively SiCl 4 、Er(TMHD) 3 、Yb(TMHD) 3 、Ce(TMHD) 3 , POCl 3 、SiF 4 etc., the specific flow rate is shown in Table 2, and the ring outer core layer 3, the ring sunken core layer 2, and the center core layer 1 were deposited in sequence, and the deposition temperature was 1850°C. After the deposition, the quartz tube is shrunk into a solid rod by using a single shrinkage process with a hydrogen flow rate of 90-120 sccm. The difference is that an outer cladding layer 5 is added to the outer layer of the preform in the comparative example, and the outer cladding layer 5 is a sunken fluorine-doped layer, which is prepared by plasma chemical vapor depo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com