Method for preparing spherical tetracalcium aluminoferrite solid solution by jointly adopting airflow crushing-radio frequency plasma technology

A technology of radio frequency plasma and tetracalcium aluminoferrite, which is applied in the field of building material preparation, can solve the problems of long cycle, low hydration activity and lack of iron phase activity, etc., and achieves favorable rheological performance regulation, hydration activity improvement, production shortening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

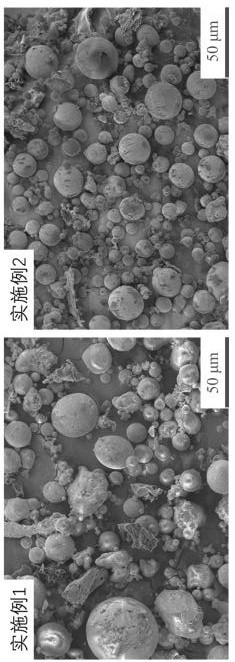

Embodiment 1

[0030] A kind of adopting plasma technology to prepare spherical C 4 AF solid solution method, combined with jet mill-RF plasma system for C 4 The preparation of AF solid solution specifically comprises the following steps:

[0031] (1) Preparation of raw meal: calcium carbonate powder (CaCO 3 ), alumina powder (Al 2 o 3 ), ferric oxide powder (Fe 2 o 3 ) and sodium sulfate (K 2 SO 4 ) according to the mass ratio of 59.74 : 15.19 : 23.92 : 1.05 is accurately weighed for use and pre-mixed.

[0032] (2) Jet milling treatment: Put the above-mentioned pre-mixed mixture powder into the jet milling equipment. The main operating parameters of the jet mill are: compressed air flow rate 6L / min, installed power 30Kw, production capacity 100Kg / h, output particle Diameter 2~60μm.

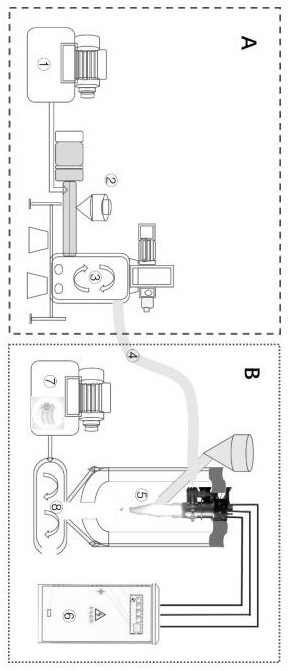

[0033] (3) RF plasma high temperature treatment, the RF plasma system consists of the following parts: RF plasma torch, RF plasma power supply, gas supply and powder feeding system, reaction chamber an...

Embodiment 2

[0036] A kind of adopting plasma technology to prepare spherical C 4 AF solid solution method, combined with jet mill-RF plasma system for C 4 The preparation of AF solid solution specifically comprises the following steps:

[0037] (1) Preparation of raw material: Carbide slag powder (Ca(OH) 2 ), aluminum hydroxide (Al(OH) 3 ), ferric oxide powder (Fe 2 o 3 ) and potassium sulfate (K 2 SO 4 ) according to the mass ratio of 48.10:25.23:25.98:0.59 and accurately weighed for use and pre-mixed.

[0038] (2) Jet milling treatment: Put the above-mentioned pre-mixed mixture powder into the jet milling equipment. The main operating parameters of the jet mill are: compressed air flow rate 10L / min, installed power 60Kw, production capacity 130kg / h, feed particle The diameter is not more than 5mm, the output particle size is 2-25μm, and the carrier gas flow is nitrogen.

[0039] (3) RF plasma high temperature treatment, the RF plasma system consists of the following parts: RF pl...

Embodiment 3

[0042] A kind of adopting plasma technology to prepare spherical C 4 AF solid solution method, combined with jet mill-RF plasma system for C 4 The preparation of AF solid solution specifically comprises the following steps:

[0043] (1) Preparation of raw meal: calcium carbonate (CaCO 3 ), aluminum ash (mainly containing Al 2 O) 3 ), high iron red mud (Fe 2 o 3 and alkali metal content) according to the mass ratio of 45.62: 17.8: 36.52, accurately weighed for use and pre-mixed.

[0044] (2) Jet milling treatment: Put the above pre-mixed mixture powder into the jet milling equipment. The main operating parameters of the jet mill are: compressed air flow rate 15L / min, installed power 60kW, production capacity 150kg / h, feed particle The diameter is not more than 8mm, the discharge particle size is 10~50μm, and the carrier airflow is air.

[0045] (3) RF plasma high temperature treatment, the RF plasma system consists of the following parts: RF plasma torch, RF plasma power...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com