Preparation method of polypeptide hydrogel capable of programmatically releasing NO and promoting angiogenesis

An angiogenesis-promoting and procedural technology, applied in prosthesis, medical science, etc., can solve the problems of increasing cost and reducing application effect, and achieve the effect of high water solubility, good biocompatibility, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

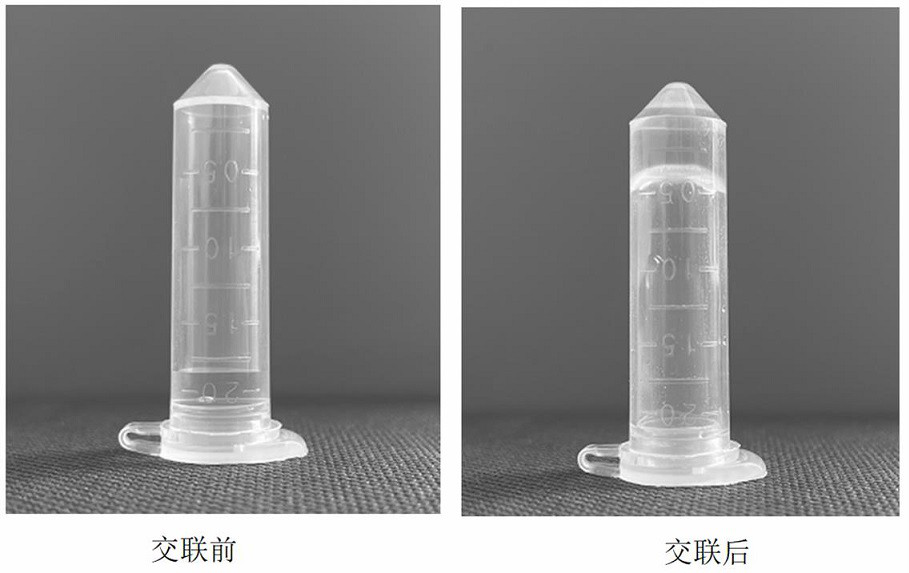

[0032] A preparation method for programmed release of NO-promoting angiogenesis polypeptide hydrogel, comprising the steps of:

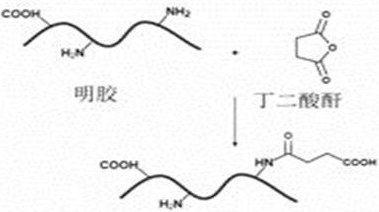

[0033] (1) Dissolve sodium carbonate in deionized water, adjust PH=7-10, add gelatin at a ratio of 50g / L, stir and dissolve at 60°C to obtain a gelatin solution.

[0034] (2) Dissolve succinic anhydride in a mixed solution of dimethyl sulfoxide and triethylamine at a ratio of 30g / L; the volume ratio of dimethyl sulfoxide to triethylamine is 25:1.

[0035] (3) Mix the solution obtained in step (1) and step (2) to obtain a mixed solution. The mass ratio of gelatin to succinic anhydride in the mixed solution is 1: 1. After stirring at room temperature for 12 hours, dilute 3 times, and use deionized water in the Dialyze at room temperature for 3 days, change the water every 15 hours, the molecular weight cut-off of the dialysis bag is 8KDa-14KDa, after the dialysis, freeze-dry to obtain the processed gelatin.

[0036] (4) Dissolve the gelatin obtained i...

Embodiment 2

[0040] A preparation method for programmed release of NO to promote angiogenesis polypeptide hydrogel, comprising the following steps:

[0041] (1) Dissolve sodium carbonate in deionized water, adjust PH=7-10, add gelatin at a ratio of 200g / L, stir and dissolve at 45°C to obtain a gelatin solution.

[0042] (2) Dissolve succinic anhydride in a mixed solution of dimethyl sulfoxide and triethylamine at a ratio of 80g / L; the volume ratio of dimethyl sulfoxide to triethylamine is 25:1.

[0043] (3) Mix the solution obtained in step (1) and step (2) to obtain a mixed solution. The mass ratio of gelatin to succinic anhydride in the mixed solution is 1:0.5. After stirring at room temperature for 48 hours, dilute to 2 times, and use deionized water in the Dialyze at room temperature for 5 days, change the water every 18 hours, the molecular weight cut-off of the dialysis bag is 8KDa-14KDa, after the dialysis, freeze-dry to obtain the processed gelatin.

[0044] (4) Dissolve the gelatin...

Embodiment 3

[0048] A preparation method for programmed release of NO-promoting angiogenesis polypeptide hydrogel, comprising the steps of:

[0049] (1) Dissolve sodium carbonate in deionized water, adjust the pH to 7-10, add gelatin at a ratio of 100g / L, stir and dissolve at a temperature of 35°C to obtain a gelatin solution.

[0050] (2) Dissolve succinic anhydride in a mixed solution of dimethyl sulfoxide and triethylamine at a ratio of 60g / L; the volume ratio of dimethyl sulfoxide to triethylamine is 25:1.

[0051] (3) Mix the solution obtained in step (1) and step (2) to obtain a mixed solution. The mass ratio of gelatin to succinic anhydride in the mixed solution is 1:0.1. After stirring at room temperature for 30 hours, dilute to 1 time, and use deionized water in the Dialyze at room temperature for 7 days, change the water every 6 hours, the molecular weight cut-off of the dialysis bag is 8KDa-14KDa, after the dialysis, freeze-dry to obtain the processed gelatin.

[0052] (4) Diss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com