Alkali-free liquid accelerator for effectively preventing sprayed concrete from crystallizing to block drainage system and preparation method of alkali-free liquid accelerator

A shotcrete and drainage system technology, applied in the field of construction engineering, can solve the problems of tunnel collapse, high cost, maintenance of the drainage system of the tunnel, etc., and achieve the effects of reducing the probability of calcium precipitation, improving blind pipe blockage, and high early strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

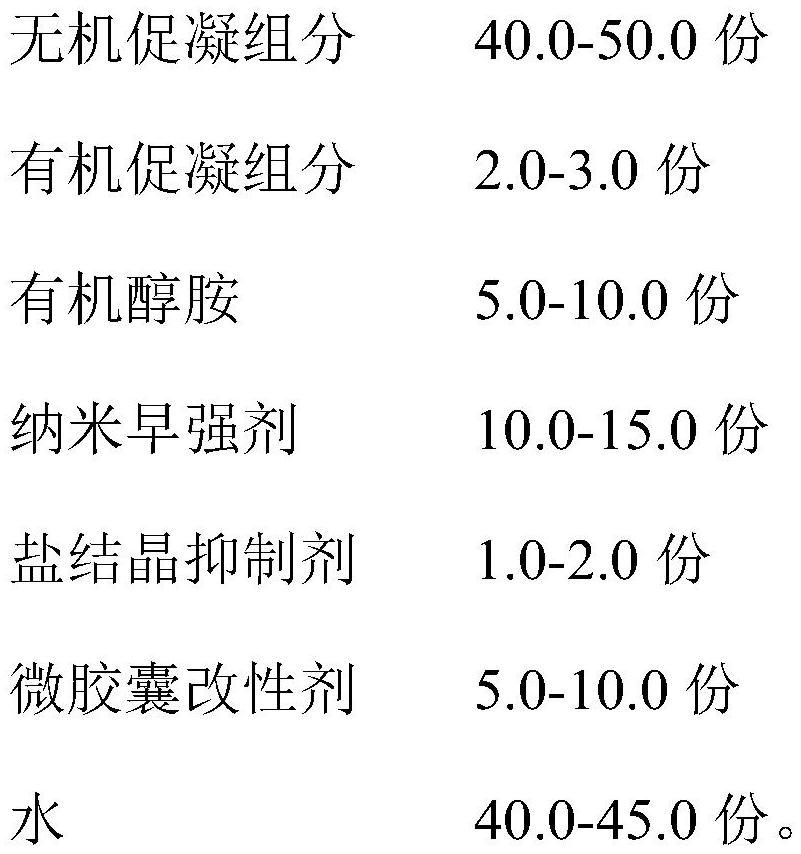

[0035] An alkali-free liquid quick-setting agent that effectively prevents shotcrete devitrification from clogging a drainage system, comprising the following raw materials in parts by mass:

[0036]

[0037] The preparation method of the microcapsule modifier is as follows:

[0038] 1) Dissolving 50g of polylactic acid in 100g of methylene chloride to obtain a capsule material solution;

[0039] 2) Slowly put 20g of activated carbon, 20g of EDTA, and 20g of citric acid into the capsule material solution sequentially under stirring at 100 rpm, finish adding in 2 hours, and after stirring for 2 hours, use ultrasonic waves with a frequency of 20kHz for 24 hours;

[0040] 3) Spray-dry the ultrasonicated mixture at 150° C. to obtain a microcapsule modifier.

[0041] The preparation method of the novel alkali-free liquid quick-setting agent that effectively prevents shotcrete crystallization from clogging the drainage system comprises the following steps:

[0042] Add 420g wat...

Embodiment 2

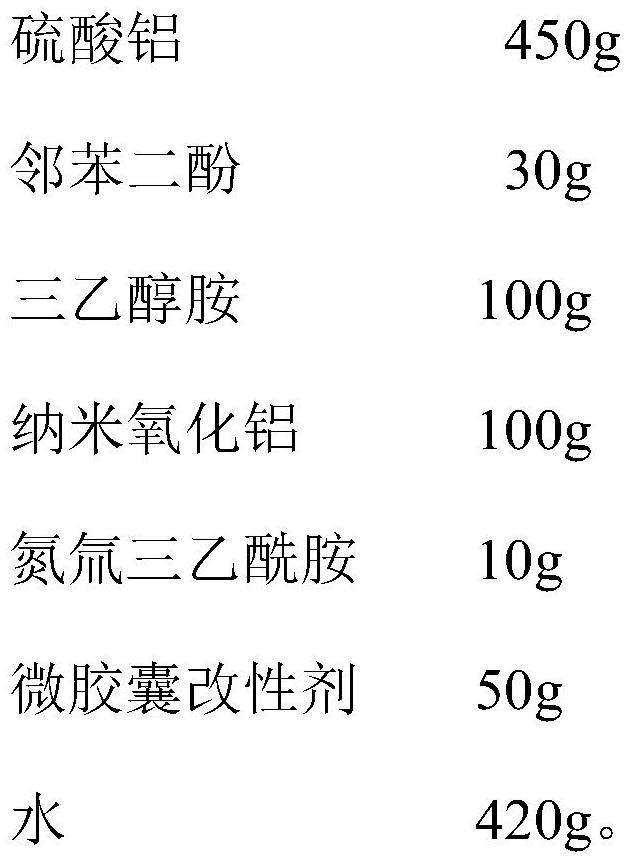

[0044] An alkali-free liquid quick-setting agent that effectively prevents shotcrete devitrification from clogging a drainage system, comprising the following raw materials in parts by mass:

[0045]

[0046] The preparation method of the microcapsule modifier is as follows:

[0047] 1) Dissolving 50g of polylactic acid in 100g of methylene chloride to obtain a capsule material solution;

[0048] 2) Slowly put 20g of ultrafine aluminum sulfate, 20g of zeolite, and 20g of citric acid into the capsule material solution under stirring at 80 rpm, and finish adding in 2 hours. After stirring for 2 hours, use ultrasonic waves with a frequency of 20kHz for 24 hours;

[0049] 3) Spray-dry the ultrasonicated mixture at 150° C. to obtain a microcapsule modifier.

[0050] The preparation method of the novel alkali-free liquid quick-setting agent that effectively prevents shotcrete crystallization from clogging the drainage system comprises the following steps:

[0051] Add 400g of w...

Embodiment 3

[0053] An alkali-free liquid quick-setting agent that effectively prevents shotcrete devitrification from clogging a drainage system, comprising the following raw materials in parts by mass:

[0054]

[0055] The preparation method of the microcapsule modifier is as follows:

[0056] 1) Dissolving 50g of polylactic acid in 100g of chloroform to obtain a capsule material solution;

[0057] 2) Slowly put 20g of activated carbon, 20g of zeolite, and 20g of succinic acid into the capsule material solution under stirring at 100 rpm, finish adding in 2 hours, and after stirring for 2 hours, use ultrasonic waves with a frequency of 20kHz for 24 hours;

[0058] 3) Spray-dry the ultrasonicated mixture at 150° C. to obtain a microcapsule modifier.

[0059] The preparation method of the novel alkali-free liquid quick-setting agent that effectively prevents shotcrete crystallization from clogging the drainage system comprises the following steps:

[0060] Add 430g of water, 50g of fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com