Preparation method and system of nano silicon carbide particle reinforced aluminum-based gradient composite material

A nano-silicon carbide and particle-reinforced aluminum technology is applied in metal processing equipment, transportation and packaging. , the effect of high degree of mechanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

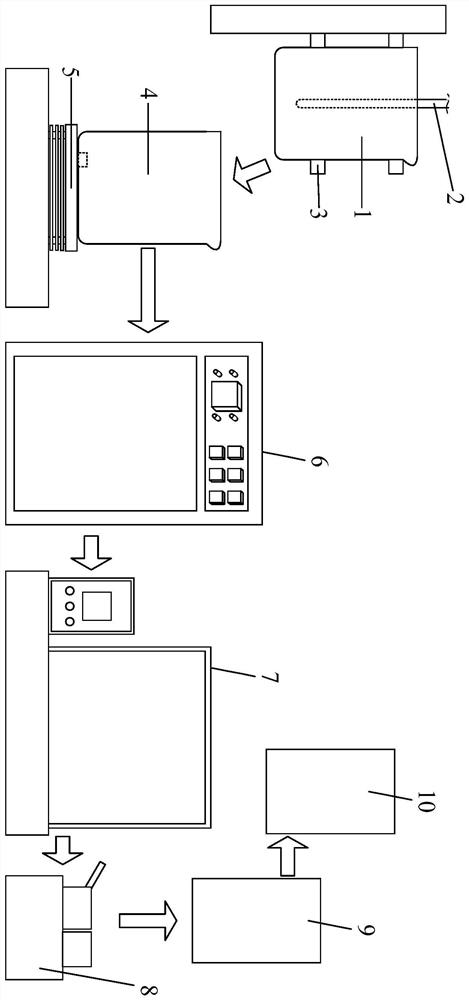

[0103] like Figure 22 , The present invention also relates to a preparation method of nano-silicon carbide particle reinforced aluminum-based gradient composite material, which adopts the above-mentioned preparation system of nano-silicon carbide particle-reinforced aluminum-based gradient composite material, and includes the following steps:

[0104] Step 1, solvent-assisted dispersion:

[0105] 1) Weigh the corresponding quality of nano-silicon carbide powder according to the predetermined volume fraction and pour it into the ultrasonic dispersion reaction cylinder 1 filled with absolute ethanol, and ultrasonically disperse it for 60min. In the mixing reaction cylinder 4, the 2014A1 alloy suspension is electromagnetically stirred by the magnetic stirrer 5; wherein,

[0106]

[0107] M 2 =M-M 1

[0108] Among them, M, M 1 and M 2 are the total weight of powder, the mass of nano-silicon carbide powder and the mass of 2014A1 alloy powder, ρ 1 and ρ 2 are the density...

Embodiment 1

[0120] Step 1, solvent-assisted dispersion:

[0121] 1) Weigh the corresponding quality of nano-silicon carbide powder according to the predetermined volume and pour it into a container filled with absolute ethanol for ultrasonic dispersion for 60min, while placing the corresponding quality 2014A1 alloy powder in a container filled with absolute ethanol. The alloy suspension is electromagnetically stirred;

[0122] 2) Add the suspension containing the silicon carbide reinforcement to the container containing the 2014A1 alloy suspension subsequently under magnetic stirring, continue magnetic stirring for 30min after adding, and let stand for settling;

[0123] 3) After the solution is clarified, pour out part of the clear liquid and dry it to obtain preliminary mixed powder;

[0124] Step 2, Mechanical Ball Milling:

[0125] The composite powder is mechanically ball-milled, and 1.0 wt% stearic acid is added in the process;

[0126] Step three, powder metallurgy:

[0127] Ac...

Embodiment 2

[0129] The steps are in Example 1 together;

[0130] Step 2 is the same as in Example 1;

[0131] Step three, powder metallurgy:

[0132] According to the method of step 1 and step 2, the nano-silicon carbide / 2014Al composite material powders with the volume of 3% and 5% of nano-silicon carbide were respectively prepared, and a layer of 3vol.% SiC / 2014A1 composite material powder was placed on the bottom layer of the mold. The head was cold-pressed for 2min under a pressure of 140MPa, the indenter was removed, a second layer of 5vol.% SiC / 2014A1 composite powder was placed, and the pressure was maintained under a pressure of 140MPa for 2min, until the two layers of composite powder with different SiC volume fractions were all put into And cold-pressed into billets.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com