Carbon-series flexible heat conduction band with high in-plane and vertical heat conduction performance and manufacturing method of carbon-series flexible heat conduction band

A carbon-based flexible, conductive tape technology, applied in the field of thermal management, can solve problems such as insufficient heat flux, different heat transfer capabilities, and reduced heat transfer efficiency, so as to increase reliability and service life, and reduce heating effect , The effect of reducing the contact thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention is illustrated below with specific examples, but not limitation of the present invention.

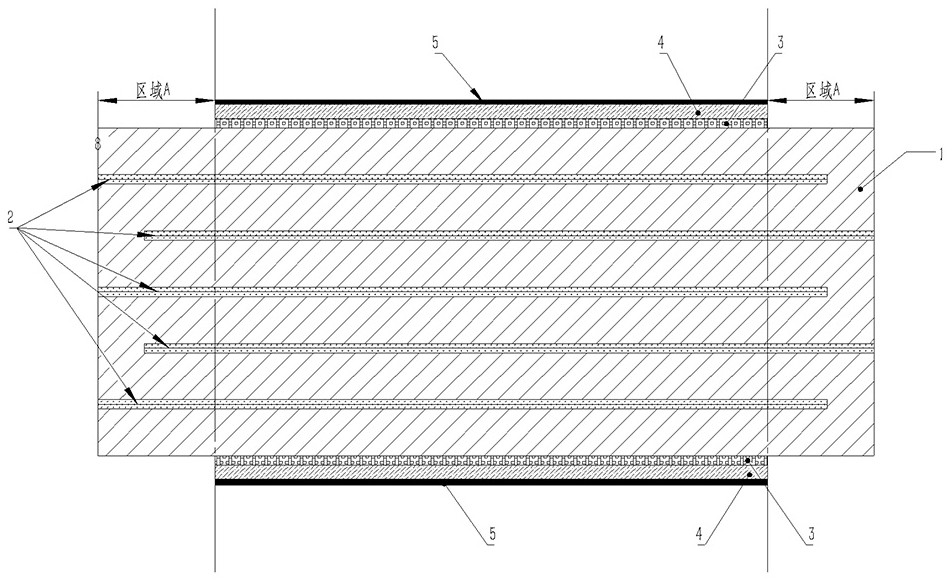

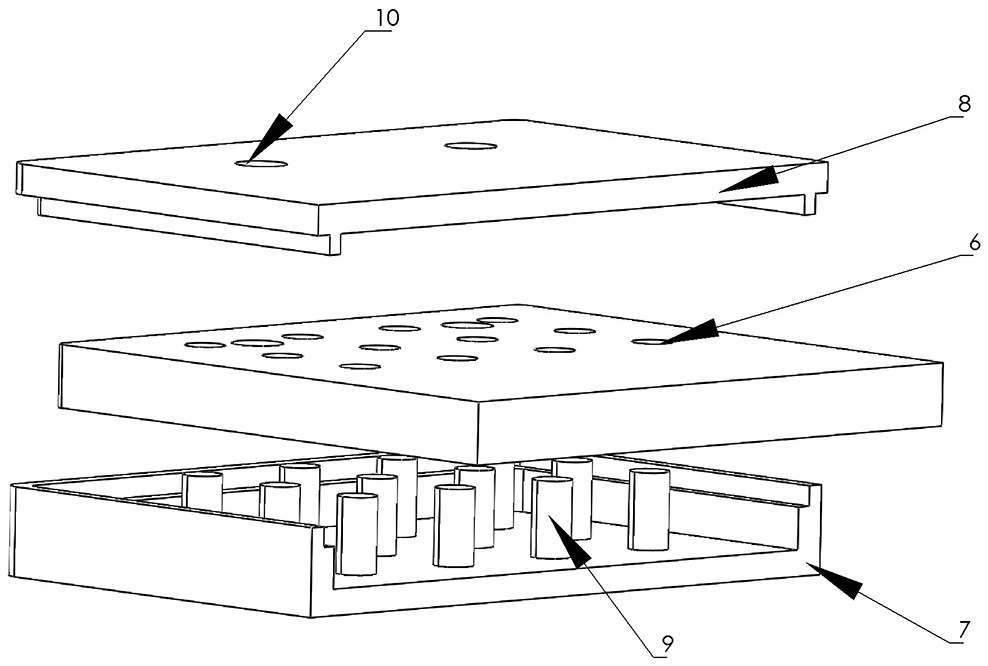

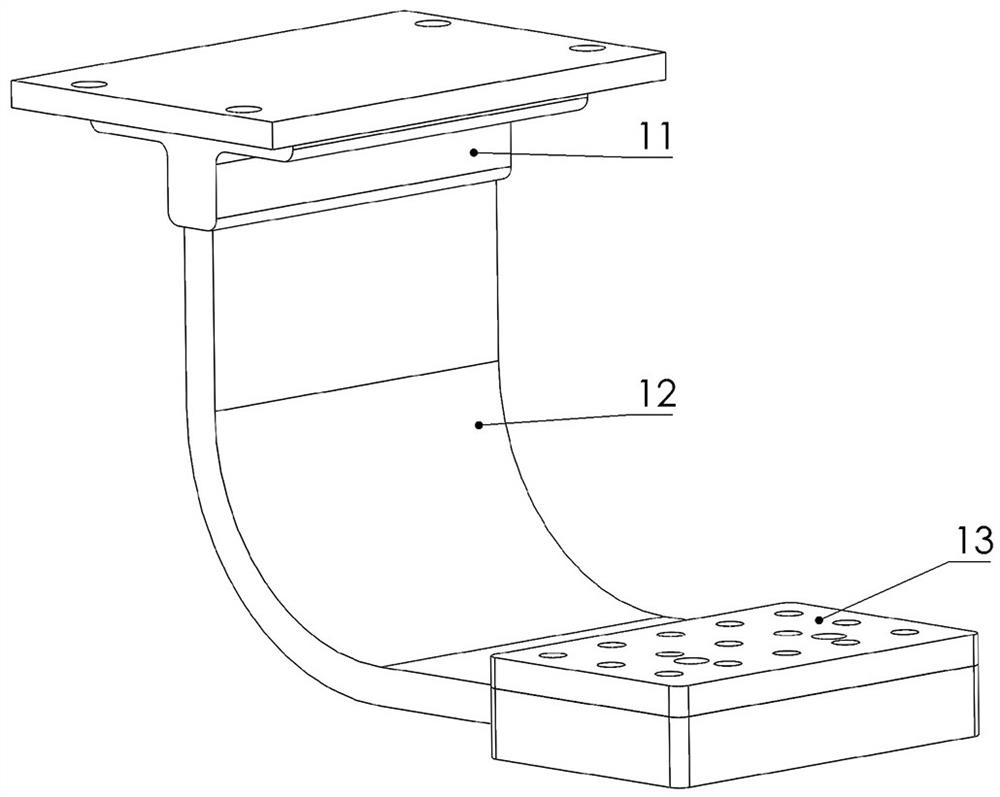

[0048]One side of flexible pyrolytic graphite of 1650mm×200mm×0.04mm is evenly coated with phenolic resin with a thickness of 0.01mm. The length direction (1650mm) is stacked in a serpentine shape with a width of 30mm, and bonded under the action of heat-sensitive adhesive to form a strip-shaped thick film (about 2.3mm thick) with a length of 200mm and a width of 30mm. Under the action of a hot press, the strip-shaped thick film is hot-pressed, and the excess adhesive layer is squeezed out to compact the strip-shaped thick film. Tightly wrap a layer of polyimide tape with a thickness of 0.1mm in the 160mm×30mm area of the middle section of the strip-shaped thick film, and then wrap two layers of aluminized polyurethane / polyester mesh film with a thickness of 0.08mm, and finally encapsulate the strong resistance on the outer layer Electric PE heat shrinkab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com