Poly-modified 2, 2-dimethyl-1, 3-propylene glycol ester as well as preparation method and application thereof

A technology of propylene glycol ester and dimethyl, which is applied in the field of polymodified 2,2-dimethyl-1,3-propylene glycol ester and its preparation, can solve the problem that the strength, modulus and gas barrier properties are difficult to meet the application requirements, Reduced thermoplastic processing performance, low molecular weight of copolyester, etc., to achieve lower temperature, excellent thermoplastic processing performance, and increase molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

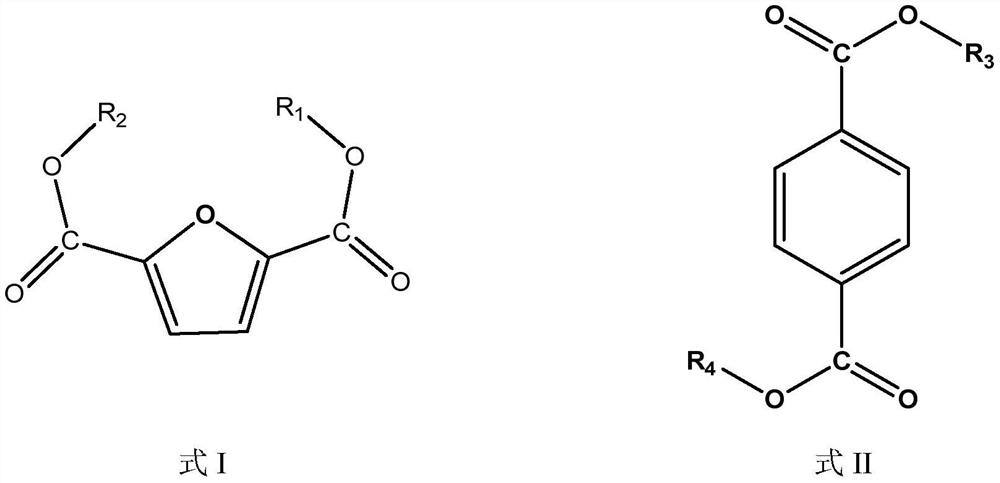

Method used

Image

Examples

Embodiment 1

[0032] Add 0.05mol dimethyl furandicarboxylate, 0.45mol dimethyl terephthalate, 0.8mol 2,2-dimethyl-1,3-propanediol, 0.00065mol anhydrous zinc acetate into a 1L reaction kettle, Vacuumize and replace with nitrogen three times, then raise the temperature to 195°C, and react for 4.5h. Then add 0.0005 mol antimony trioxide, 0.002 mol triphenyl phosphate, 0.001 mol antioxidant-1010, raise the temperature to 280°C, slowly evacuate to below 40Pa, react for 4.0 h, blow in nitrogen, add 0.00035 mol toluene diisocyanate (TDI), 280°C, continue to react for 0.6h to obtain poly-modified 2,2-dimethyl-1,3-propanediol ester.

[0033] The polymodified 2,2-dimethyl-1,3-propanediol ester obtained in this example has an intrinsic viscosity of 1.09 dL / g and a molecular weight of 6.5×10 4 g / mol, the tensile strength is 67.2MPa, the tensile modulus is 2.6GPa, and the carbon dioxide gas barrier performance is 1.3×10 -11 cm 3 cm / cm 2 ·s·cmHg, oxygen gas barrier performance is 1.0×10 -11 cm 3 cm...

Embodiment 2

[0035] Add 0.08mol dimethyl furandicarboxylate, 0.42mol dimethyl terephthalate, 0.8mol 2,2-dimethyl-1,3-propanediol, 0.00075mol anhydrous zinc acetate into a 1L reaction kettle, Vacuumize and replace with nitrogen three times, then raise the temperature to 190°C, and react for 5.0h. Then add 0.00075 mol of antimony trioxide, 0.001 mol of triphenyl phosphate, 0.0005 mol of antioxidant-1010, raise the temperature to 280°C, slowly evacuate to below 50Pa, react for 3.0 hours, blow in nitrogen, add 0.00025 mol of toluene diisocyanate (TDI), continue to react at 280°C for 1.0h to obtain poly-modified 2,2-dimethyl-1,3-propanediol ester.

[0036] The polymodified 2,2-dimethyl-1,3-propanediol ester obtained in this example has an intrinsic viscosity of 0.93 dL / g and a molecular weight of 5.4×10 4 g / mol, the tensile strength is 63.0MPa, the tensile modulus is 2.0GPa, and the carbon dioxide gas barrier performance is 1.2×10 -11 cm 3 cm / cm 2 ·s·cmHg, oxygen gas barrier performance is ...

Embodiment 3

[0038] Add 0.1mol dimethyl furandicarboxylate, 0.4mol dimethyl terephthalate, 0.8mol 2,2-dimethyl-1,3-propanediol, 0.0005mol anhydrous zinc acetate into a 1L reaction kettle, Vacuumize and replace with nitrogen three times, then raise the temperature to 190°C, and react for 4.0h. Then add 0.001mol antimony trioxide, 0.001mol triphenyl phosphate, and 0.001mol antioxidant-1076, raise the temperature to 260°C, slowly evacuate to below 20Pa, react for 4.0h, pass nitrogen gas, and add 0.001mol diphenyl Methane diisocyanate (MDI) was reacted at 260°C for 1.2 hours to obtain poly-modified 2,2-dimethyl-1,3-propanediol ester.

[0039] The intrinsic viscosity of the polymodified 2,2-dimethyl-1,3-propanediol ester obtained in this example is 1.07dL / g, and the molecular weight is 6.2×10 4 g / mol, the tensile strength is 65.7MPa, the tensile modulus is 2.1GPa, and the carbon dioxide gas barrier performance is 1.1×10 -11 cm 3 cm / cm 2 ·s·cmHg, oxygen gas barrier performance is 1.0×10 -11...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| barrier rate | aaaaa | aaaaa |

| barrier rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com