Preparation and application method of self-repairing flame-retardant molten-drop-resistant wear-resistant polyurethane coating

A polyurethane coating, self-healing technology, used in polyurea/polyurethane coatings, fire retardant coatings, epoxy resin coatings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

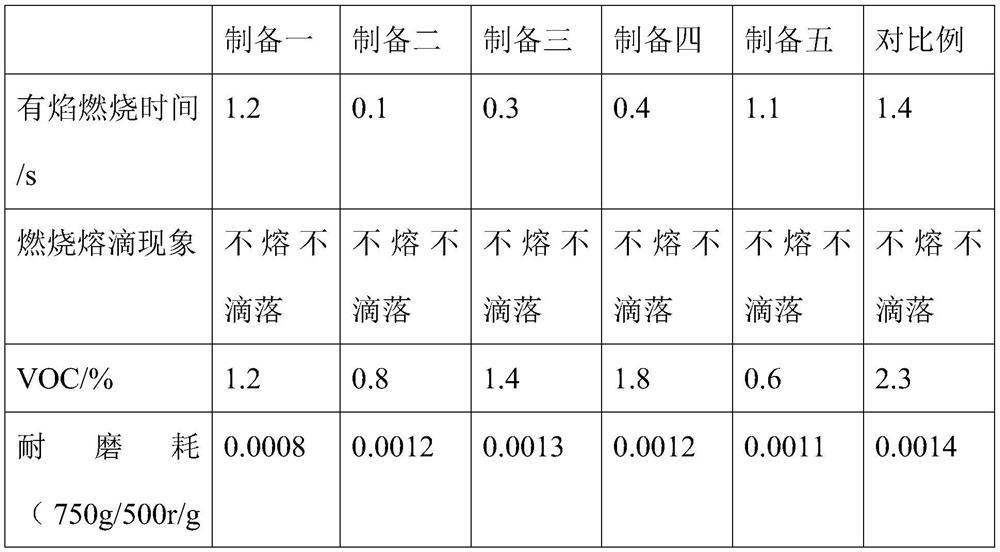

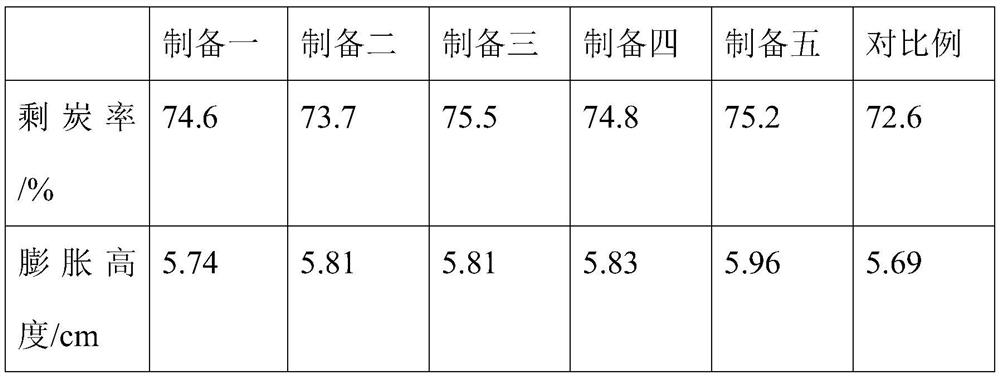

Examples

preparation example 1

[0037] The preparation method of self-repairing flame-retardant, droplet-resistant, wear-resistant polyurethane coating is characterized in that the following steps:

[0038] (1) Add 10 g of 15-micron hollow glass beads (abbreviated as HGB) and 90 mL of sodium hydroxide solution with a mass fraction of 10% in a three-neck flask protected by nitrogen, raise the temperature of the system to 70° C. and stir for 2 h to obtain the product. Wash with filtered water until neutral, then add 90g of ethanol and 10g of deionized water to the obtained suction-filtered product, and ultrasonically disperse for 30min to obtain a HGB-OH dispersion; add aminopropyltriethoxysilane to the HGB-OH dispersion for coupling Add 0.1 g of 4-bromoaniline and 0.1 g of 4-bromoaniline, heat up to 70 ° C and stir for 2 h, then filter with suction, wash with 15 mL of ethanol in the Buchner funnel three times during the suction filtration (that is, wash with 15 mL of ethanol for each suction filtration, the sa...

preparation example 2

[0048] The preparation method of self-repairing flame-retardant, droplet-resistant, wear-resistant polyurethane coating is characterized in that the following steps:

[0049](1) Add 10 g of 65-micron hollow glass beads (abbreviated as HGB) and 90 mL of potassium hydroxide solution with a mass fraction of 10% in a three-necked flask protected by nitrogen, raise the temperature of the system to 85 ° C and stir for 3 h, and the obtained product is suction-filtered Wash with water until neutral, then add 90g of ethanol and 10g of deionized water to the obtained suction filtration product, and ultrasonically disperse for 40min to obtain a HGB-OH dispersion; add aminopropyltriethoxysilane coupling agent to the HGB-OH dispersion 0.2g and 0.1g of 4-bromoaniline, heated up to 85°C and stirred for 3h, then filtered with suction, washed three times with 15mL of ethanol in the Buchner funnel during the suction filtration, and dried the product in vacuum at 70°C for 14h to obtain HGB-NH 2 ...

preparation example 3

[0059] The preparation method of self-repairing flame-retardant, droplet-resistant, wear-resistant polyurethane coating is characterized in that the following steps:

[0060] (1) Add 10 g of 40-micron hollow glass beads (abbreviated as HGB) and 90 mL of sodium hydroxide solution with a mass fraction of 10% in a nitrogen-protected reaction vessel, raise the temperature of the system to 75° C. and stir for 2.5 h, and the obtained product is pumped Wash with filtered water until neutral, then add 90 g of ethanol and 10 g of deionized water to the obtained suction filtration product, and disperse it ultrasonically for 35 minutes to obtain a HGB-OH dispersion; add aminopropyltriethoxysilane to the HGB-OH dispersion for coupling Add 0.15 g of 4-bromoaniline and 0.1 g of 4-bromoaniline, raise the temperature to 75 ° C and stir for 2.5 h, then filter with suction, wash three times with 15 mL of ethanol in the Buchner funnel during the suction filtration, and dry the product in vacuum a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com