Guanidine gum fracturing fluid gel capable of reducing pH dependence, guanidine gum fracturing fluid system and preparation method and application thereof

A fracturing fluid and gel technology, applied in chemical instruments and methods, drilling compositions, titanium organic compounds, etc., can solve the problems of extensive use of fracturing construction, cumbersome synthesis methods, human injury, etc. The size of the joint agent, the effect of simple method and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] A preparation method of guar gum fracturing fluid gel system, the steps are as follows:

[0062] (1) Dissolve isopropanol and triethanolamine in ethylene glycol according to the mass ratio of 1:2 and mix evenly. The mass ratio of ethylene glycol to boric acid is 20:1. According to 1:2 (isopropanol: boric acid ) to a mass ratio of boric acid, adjust the temperature to 65°C and continue to stir until the boric acid is completely dissolved to form a mixed solution. According to the mass ratio of 1:20 (tetraisopropyl titanate: mixed solution), tetraisopropyl titanate was added to the above mixed solution, the temperature was raised to 75°C, and a stable organic Boron-titanium crosslinker solution.

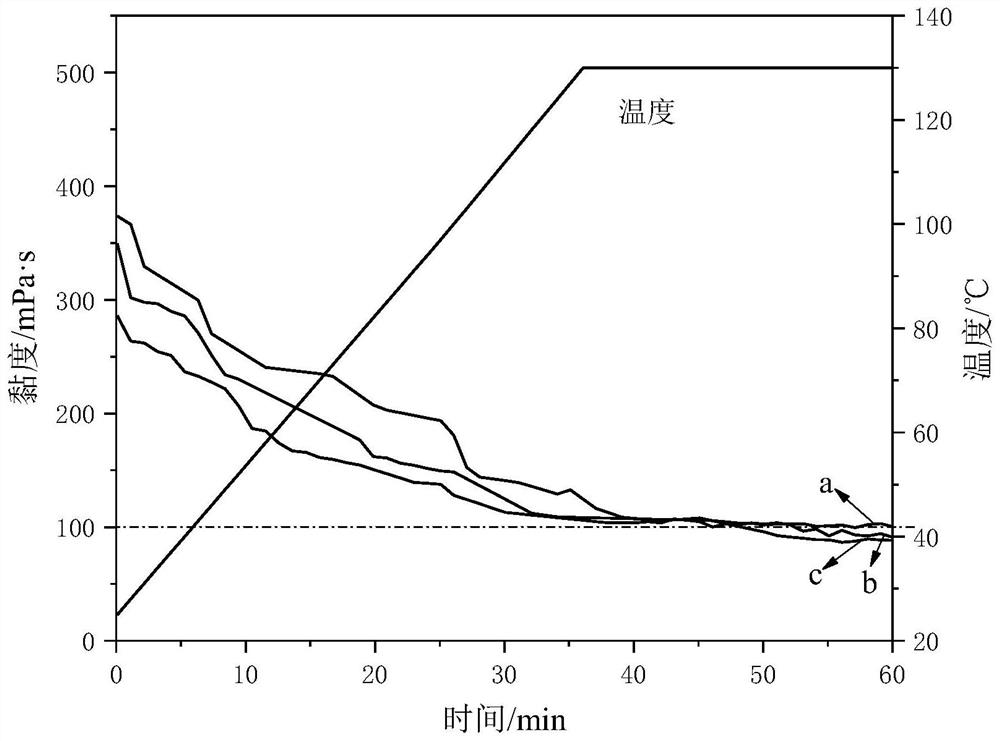

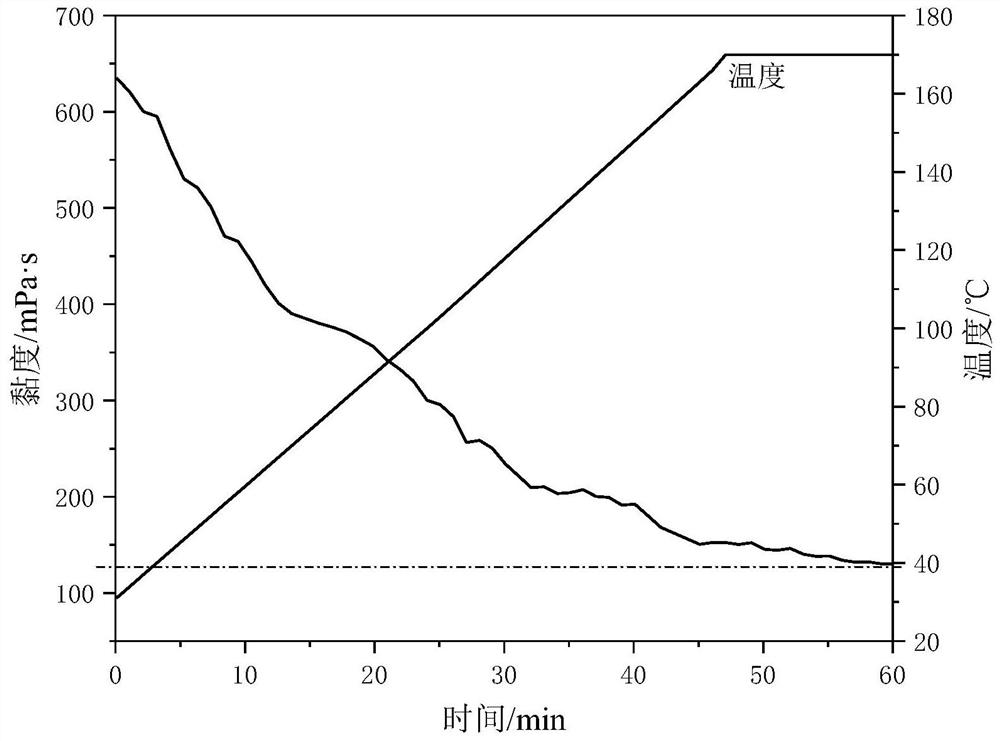

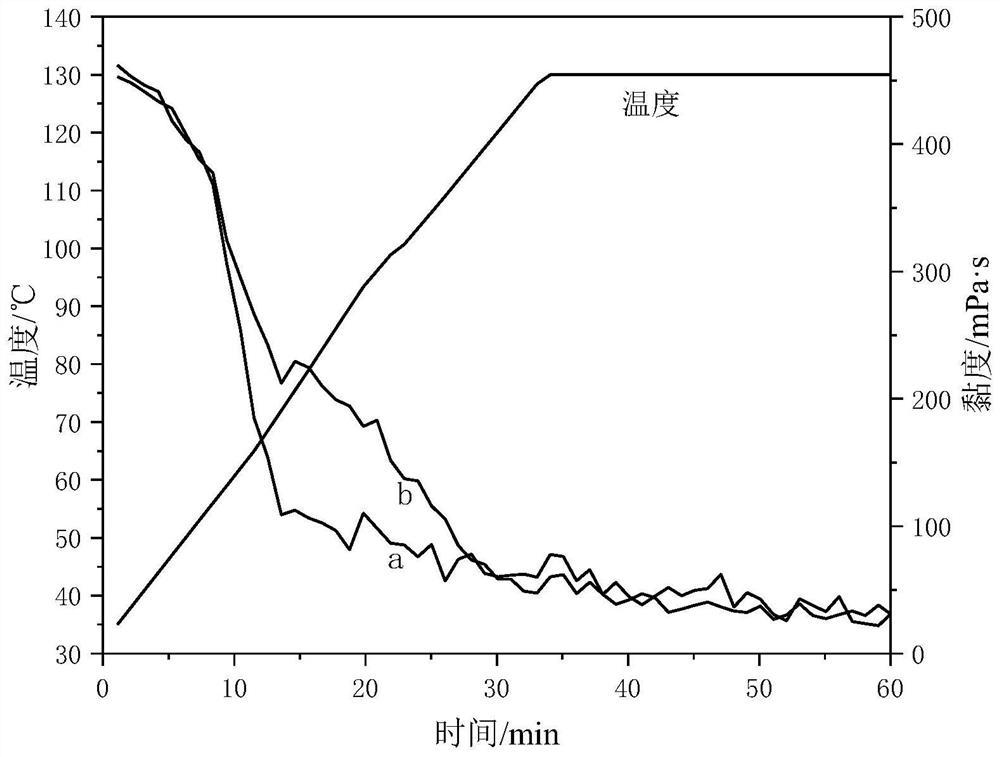

[0063] (2) prepare concentration 0.3% hydroxypropyl guar gum solution and make it fully swell, add 0.1% average particle diameter and be the nano-silica (Shanghai Naiou Nano Technology Co., Ltd., 99.9%) containing active hydroxyl of 20nm and mix Evenly, the nanoparticles are c...

Embodiment 2

[0065] A preparation method of guar gum fracturing fluid gel system, the steps are as follows:

[0066] Propanol and triethanolamine are dissolved in ethylene glycol according to the ratio of 1:2 and mixed evenly. The mass ratio of ethylene glycol and borax is 15:1. Add borax according to the ratio of 1:2 (propanol: borax), adjust The temperature is 65°C and the stirring is continued until the borax is completely dissolved to form a mixed solution. Add butyl titanate to the above mixed solution at a mass ratio of 1:30 (butyl titanate: mixed solution), raise the temperature to 75°C, and continue the reaction for 3 hours to obtain a stable organic boron titanium crosslinking agent solution .

[0067] Prepare concentration 0.25% hydroxypropyl guar gum solution and make it fully swell, add 0.12% average particle diameter and be the nano-titanium dioxide (Aladdin reagent (Shanghai) Co., Ltd., anatase, hydrophilic lipophilic type, 99.8%) and mix uniformly, so that the nanoparticle...

Embodiment 3

[0069] A preparation method of guar gum fracturing fluid gel system, the steps are as follows:

[0070] Dissolve glycerol and triethanolamine in ethylene glycol at a ratio of 1:3 and mix evenly. The mass ratio of ethylene glycol to boric acid is 18:1. Add boric acid at a ratio of 1:2 (glycerol: boric acid) , adjust the temperature to 65°C and keep stirring until the boric acid is completely dissolved to form a mixed solution. Add tetraisopropyl titanate to the above mixed solution at a ratio of 1:30 (tetraisopropyl titanate: mixed solution), raise the temperature to 75°C, and continue the reaction for 3 hours to obtain a stable organic boron titanium Crosslinker solution.

[0071] Prepare concentration 0.15% hydroxypropyl guar gum solution and make it fully swell, add 0.08% diameter and be 50nm, the nano-cellulose (Jiangsu North Century Cellulose Material Co., Ltd.) that length is 400nm and mix homogeneously, make nanoparticle be dispersed in completely In the guar gum solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com