Composite structure AlN seed crystal for PVT and preparation and application thereof

A composite structure and seed crystal technology, which is applied in crystal growth, single crystal growth, single crystal growth, etc., can solve the problem that the processing accuracy such as warpage cannot be less than microns, affects the purity and quality of crystals, and reduces the diameter of crystals. speed and other issues to achieve the effect of improving the quality of crystal growth, reducing cracks and dislocations, and reducing the generation of pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

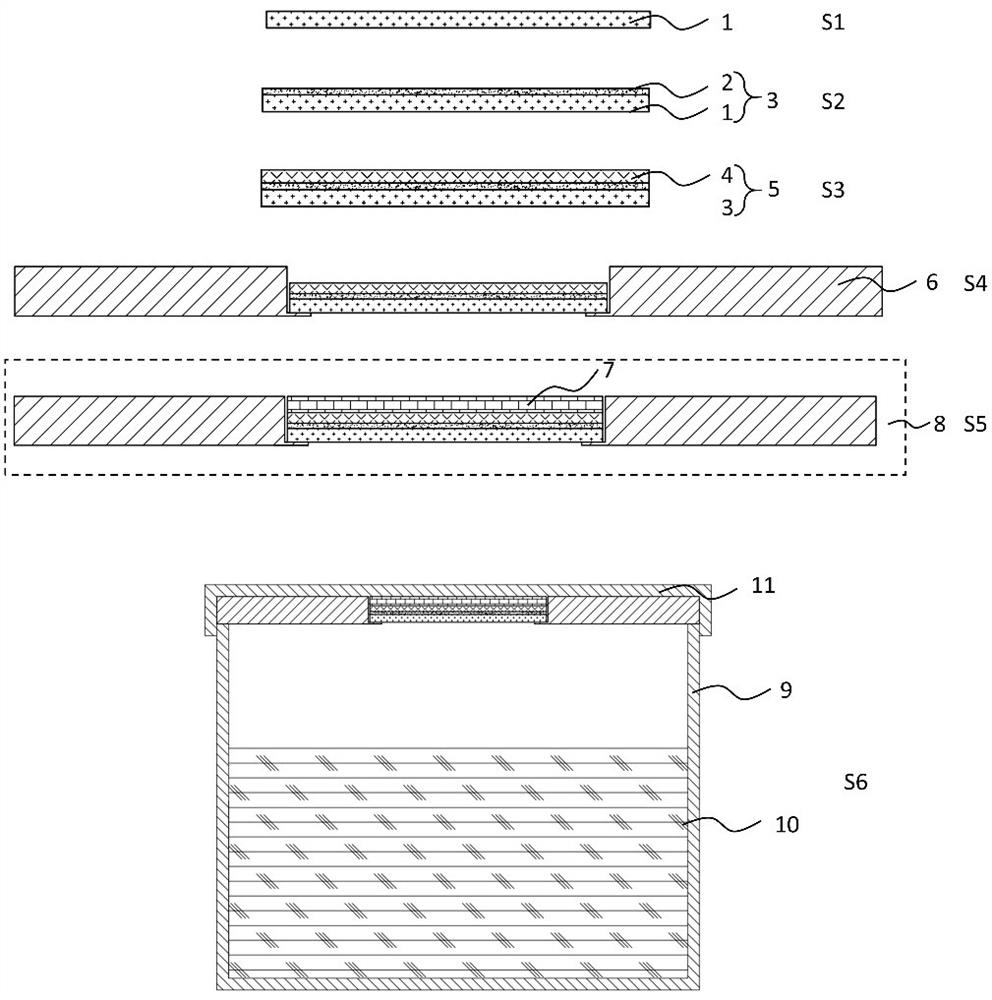

[0023] First, AlN seed crystals with a composite structure are prepared, as shown in the attached figure 1 As described above, it mainly includes the steps of: selecting an AlN single wafer 1 as an aluminum nitride seed wafer (S1), coating the surface of the aluminum nitride seed wafer with a back-sealing film 2 (S2), and coating an AlN thick film 4 on the back-sealing film to form a composite structure AlN seed crystal (S3). The AlN seed crystal of the composite structure is placed in the accessory tank (S4), the back cover metal sheet is added (S5), and the accessory tank is assembled on the top of the crucible for crystal epitaxial growth (S6). Attached below figure 1 , the specific steps of this embodiment are described in detail as follows:

[0024] 1) Step S1: A double-sided polished AlN single wafer is prepared as an aluminum nitride seed wafer 1 with a diameter of 51 mm. The thickness H0 of the seed wafer 1 is 0.5mm, and both sides are treated by chemical mechanical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com