Long-life high-temperature-resistant polyolefin insulating material as well as preparation method and application thereof

A long-life, insulating material technology, used in insulators, organic insulators, plastic/resin/wax insulators, etc., can solve the problem of flame retardant properties of materials that cannot meet the technical requirements, and achieve high flexibility, heat resistance, etc. Good cracking performance and good workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

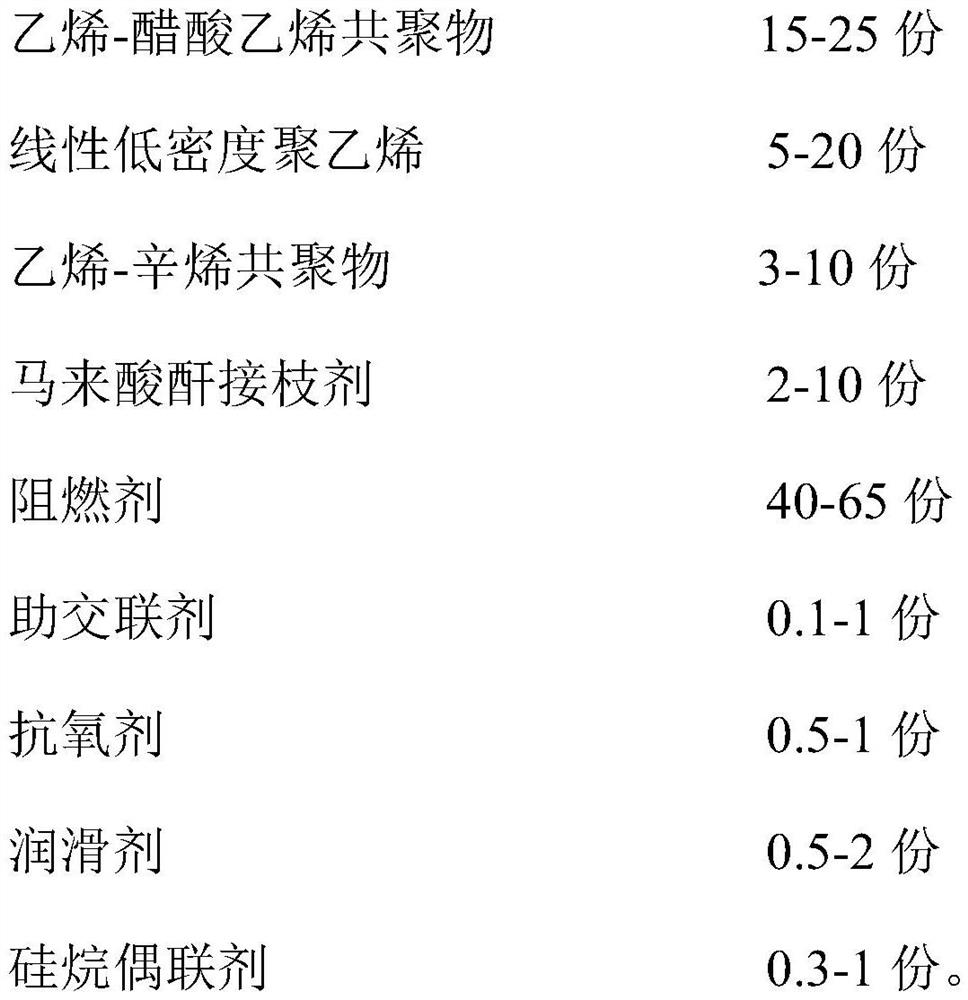

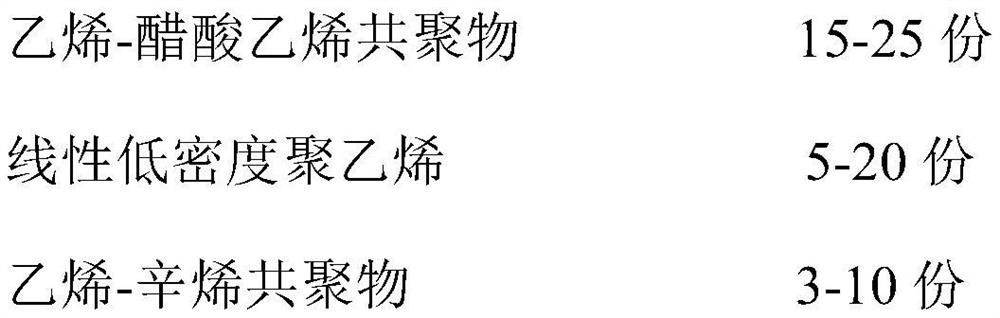

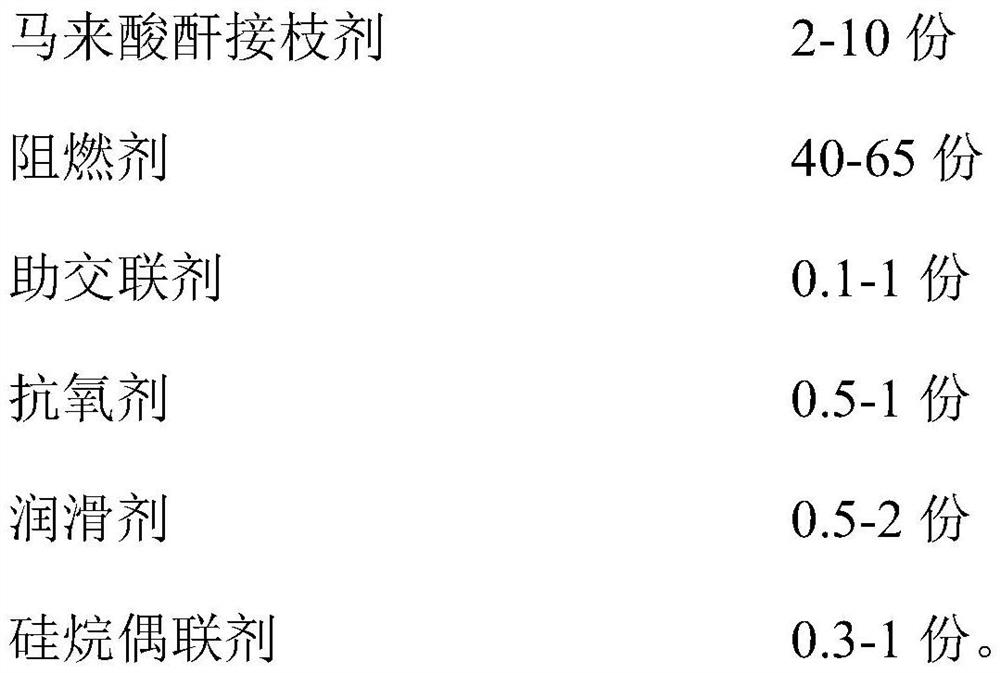

[0043] The long-life, high-temperature, weather-resistant, low-smoke, halogen-free, radiation-crosslinked polyolefin insulating material of this embodiment includes the following components in parts by weight:

[0044]

[0045]

[0046] Among them, the VA content of ethylene-vinyl acetate copolymer is 26.5%, the model is 7470k, the linear low density polyethylene is Borealis bimodal polyethylene, the model is 2230, and the ethylene-octene copolymer is Dow's ethylene-octene Alkene copolymer 3080, the grafting ratio of maleic anhydride grafting agent is 0.9%, and the antioxidant is a compound mixture of 0.4 parts of hindered phenols 1010, 0.2 parts of thioesters DLTP and 0.1 parts of copper anti-copper agent 1024 , the auxiliary crosslinking agent is TAIC, the lubricant is silicone masterbatch with a weight average molecular weight of 500,000, the flame retardant is aluminum hydroxide, the surface is modified by silane, the particle size is less than or equal to 2 μm, and t...

Embodiment 2

[0050] The difference between this example and Example 1 lies in the change of the number of antioxidants, wherein the total number of antioxidants is 1.2 parts, which are respectively 0.6 parts of hindered phenols 1010 and 0.4 parts of thioesters DLTP With the compound mixture of 0.2 part of anti-copper agent 1024, others are all the same as those of Example 1.

[0051] The preparation method of this embodiment is also the same as that of Example 1.

Embodiment 3

[0053] The difference between this example and Example 2 is that the number of parts of the auxiliary crosslinking agent TAIC changes to 0.8 parts, and the others are the same as those of Example 2.

[0054] The preparation method of this embodiment is also the same as that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com