Preparation method of black phosphorus/cobalt tetroxide composite oxygen evolution electrocatalyst

A technology of cobalt tetroxide and electrocatalyst, which is used in electrodes, electrolysis components, electrolysis process and other directions to achieve the effect of overcoming poor stability, excellent long-term stability and mild synthesis conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

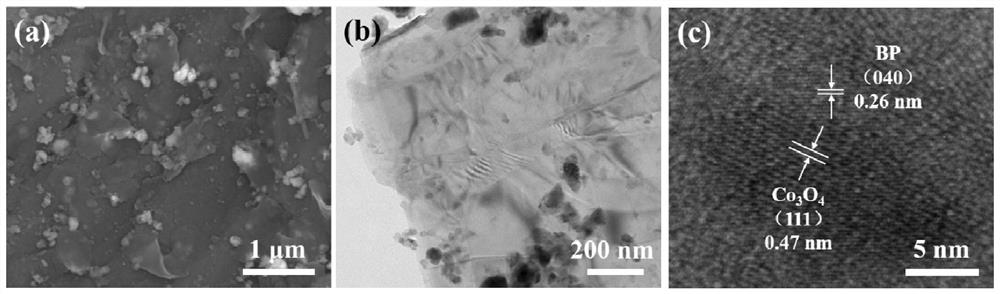

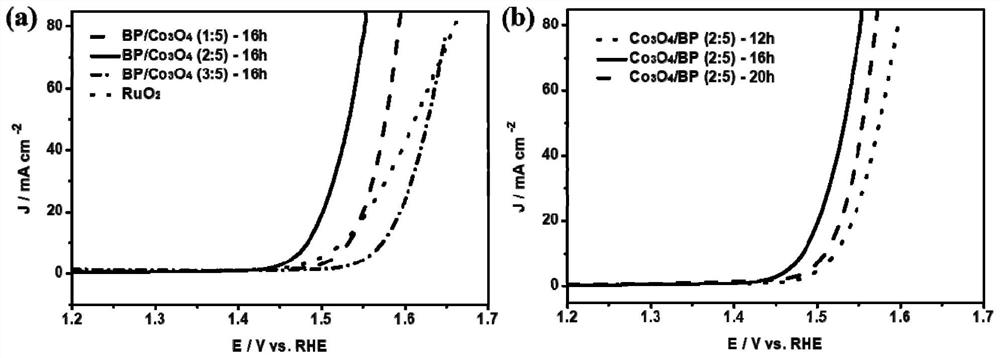

[0030] When the mass ratio of black phosphorus to cobalt tetroxide is 2:5, and the ball milling time is 16h, the prepared oxygen evolution electrocatalyst.

[0031] (1) Accurately weigh 0.5g of commercial cobalt powder with a particle size of about 100-400nm in a 50ml ceramic crucible, and make it heat up to 550°C at a heating rate of 10°C / min in an air atmosphere. After heat treatment for 2 hours, the particle size is obtained. About 200 ~ 800nm pure Co 3 O 4 nanomaterials.

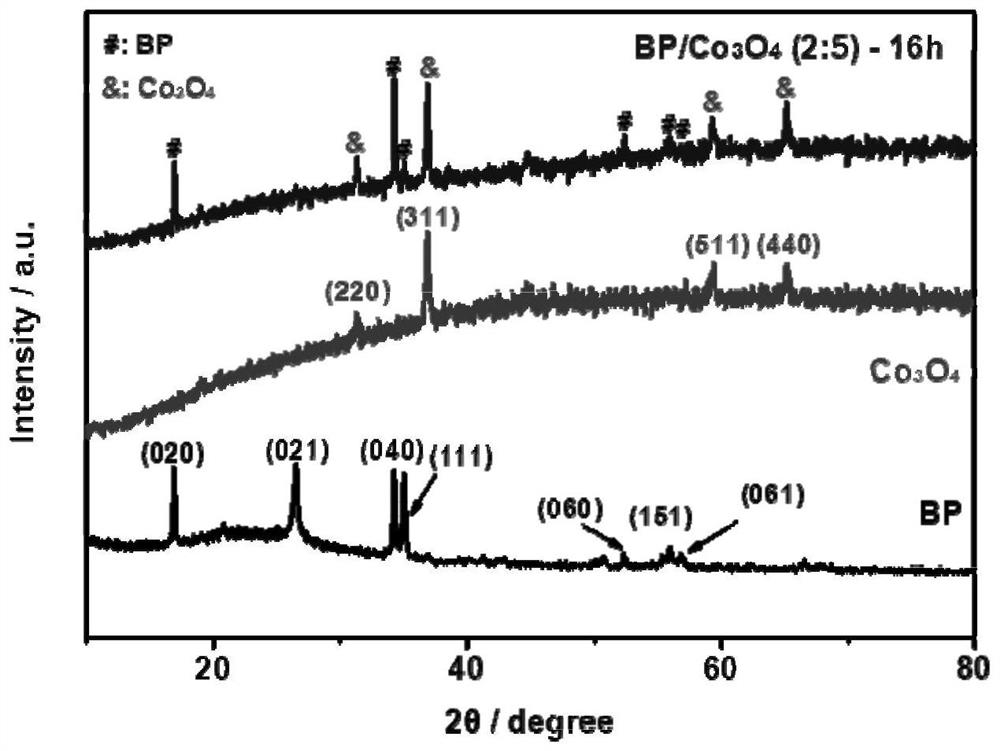

[0032] figure 1 The Co prepared in this example 3 O 4 XRD patterns of nanomaterials, from figure 1 It can be seen that the commercial cobalt powder has been completely converted into Co after the high temperature oxidation process in the air 3 O 4 .

[0033] (2) Accurately weigh 0.4 g of the obtained Co at room temperature 3 O 4 and 0.16g of black phosphorus bulk. It was placed in a 200 ml vacuum ball milling jar containing 20 agate balls with a mass of 1.5 g and 80 agate balls with a mass o...

Embodiment 2

[0038] When the mass ratio of black phosphorus to cobalt tetroxide is 1:5, and the ball milling time is 16h, the prepared oxygen evolution electrocatalyst.

[0039] (1) Accurately weigh 0.5g of commercial cobalt powder with a particle size of about 100 to 400nm in a 50ml ceramic crucible, make it heat up to 550°C at a heating rate of 10°C / min in an air atmosphere, and obtain the particle size after heat treatment for 2 hours. About 200 ~ 800nm pure Co 3 O 4 nanomaterials.

[0040] (2) Accurately weigh 0.4 g of Co obtained in (1) at room temperature 3 O 4 and 0.08g black phosphorus block. It was placed in a 200 ml vacuum ball milling jar containing 20 agate balls with a mass of 1.5 g and 80 agate balls with a mass of 0.3 g.

[0041] (3) Measure 100 ml of nitrogen-saturated oleyl amine and pour it into a ball mill, and after wet grinding at 500 rpm for 16 hours, centrifugation, alcohol washing and drying in an oxygen-free glove box to obtain black phosphorus nanosheets / ...

Embodiment 3

[0043] When the mass ratio of black phosphorus to cobalt tetroxide is 3:5, and the ball milling time is 16h, the prepared oxygen evolution electrocatalyst.

[0044] (1) Accurately weigh 0.5g of commercial cobalt powder with a particle size of about 100 to 400nm in a 50ml ceramic crucible, make it heat up to 550°C at a heating rate of 10°C / min in an air atmosphere, and obtain the particle size after heat treatment for 2 hours. About 200 ~ 800nm pure Co 3 O 4 nanomaterials.

[0045] (2) Accurately weigh 0.4 g of Co obtained in (1) at room temperature 3 O 4 and 0.24g black phosphorus block. It was placed in a 200 ml vacuum ball milling jar containing 20 agate balls with a mass of 1.5 g and 80 agate balls with a mass of 0.3 g.

[0046] (3) Measure 100ml of nitrogen-saturated N,N-dimethylformamide and pour it into a ball mill. After wet grinding at 500 rpm for 16 hours, centrifuge, alcohol wash and dry in an oxygen-free glove box. , prepared black phosphorus nanosheets / coba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com