Seedling culture substrate sheet and preparation method thereof

A seedling raising substrate and substrate technology, applied in the direction of substrate fertilizer, fertilizer made from biological waste, application, etc., can solve problems such as lack of pest control and weed production, unreasonable use of seedling strengthening agents, unreasonable bed soil configuration, etc. , to achieve the effect of being suitable for mechanical operation, good water and fertilizer retention performance, and increasing farmers' income

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

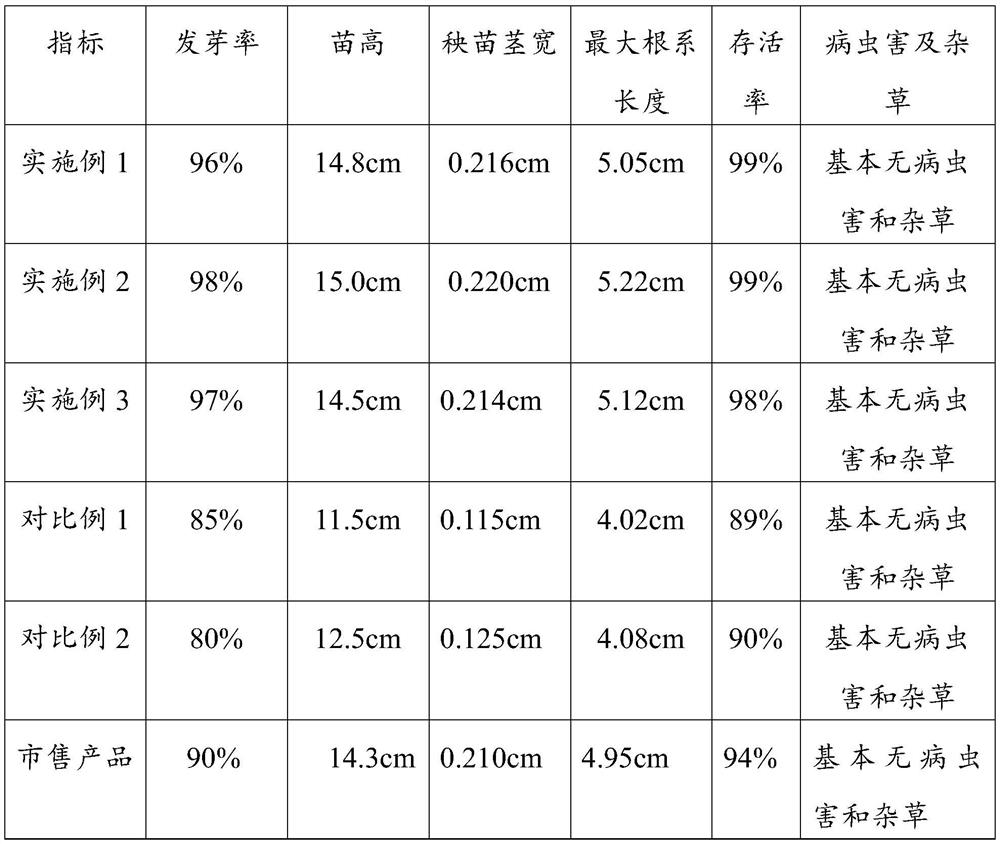

Examples

Embodiment 1

[0037] This embodiment provides a method of preparing a seedlings, including the following steps:

[0038] S1, the collected aqueous content of 5% of the corn core and the rice husk is pretreated to a particle size of 5 mm or less;

[0039] S2, the water content of 68% is mixed with the pulverized corn core after 80:20, and then the 1 ‰ of the organic fungus is added. At this time, the carbon nitrogen ratio of the material is detected is 25: 1, the aqueous content is 50%, pH is 6.5, and the total nutrient content is 4%;

[0040] S3, the mixed material is sent to the long groove fast fermentation reactor to perform micro-oxygen fermentation, control the oxygen concentration of 12%, and the flushing machine is used for rolling machine every 5 days, and the air required during the fermentation process is adjusted. The adjustment moisture content is 50%, temperature at 50 ° C, and the fermentation time is 30 days;

[0041] S4, the fermented material added 2% full nutrient preparation ...

Embodiment 2

[0046] This embodiment provides a method of preparing a seedlings, including the following steps:

[0047] S1, the collected water content of 4% is pulverized and straw preprocessing to a particle diameter of 5 mm or less;

[0048] S2, the water content of less than 65% is mixed with the pulverized corn core in accordance with the mass ratio of 85:15, and then 2 ‰ of the organic fungus, at this time, the carbon nitrogen ratio of the material is detected is 26. : 1, the aqueous content is 53%, pH is 7.0, and the total nutrient content is 4%;

[0049] S3, the mixed material is sent to the long tank fast fermentation reactor for micro-oxygen fermentation, control the oxygen concentration of 15%, and the floring machine is used for flushing machine every 6 days, and the air required during the fermentation process is adjusted. The moisture content is adjusted at 55%, the temperature is 60 ° C, the fermentation time is 40 days;

[0050] S4, the material after fermentation is added to t...

Embodiment 3

[0055] This embodiment provides a method of preparing a seedlings, including the following steps:

[0056] S1, the collected aqueous content of 5% is pulverized and preprocessed to the wood chip to 5 mm or less;

[0057] S2, the water content of 65% is mixed with the pulverized corn core after 80:18, and then the 1.5 ‰ of the organic fungus is added, and the carbon nitrogen ratio of the material is detected is 27: 1, the aqueous content is 57%, pH is 7.5, and the total nutrient content is 5%;

[0058] S3, send the mixed material into the long tank fast fermentation reactor for micro-oxygen fermentation, control the oxygen concentration 20%, the flushing machine is used for rolling machine every 7 days, and the air required during the fermentation process is adjusted. The moisture content is adjusted at 58%, the temperature is 65 ° C, the fermentation time is 30 days;

[0059] S4, the fermented material added 2% full nutrient preparation mixed uniform and continued to pile up the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com