Fluorescent body, method for manufacturing same, and light-emitting device using same

A light-emitting device and phosphor technology, applied in the field of phosphors, can solve the problems of easy reduction of the brightness of phosphors and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0154] [Example 1: Phosphor]

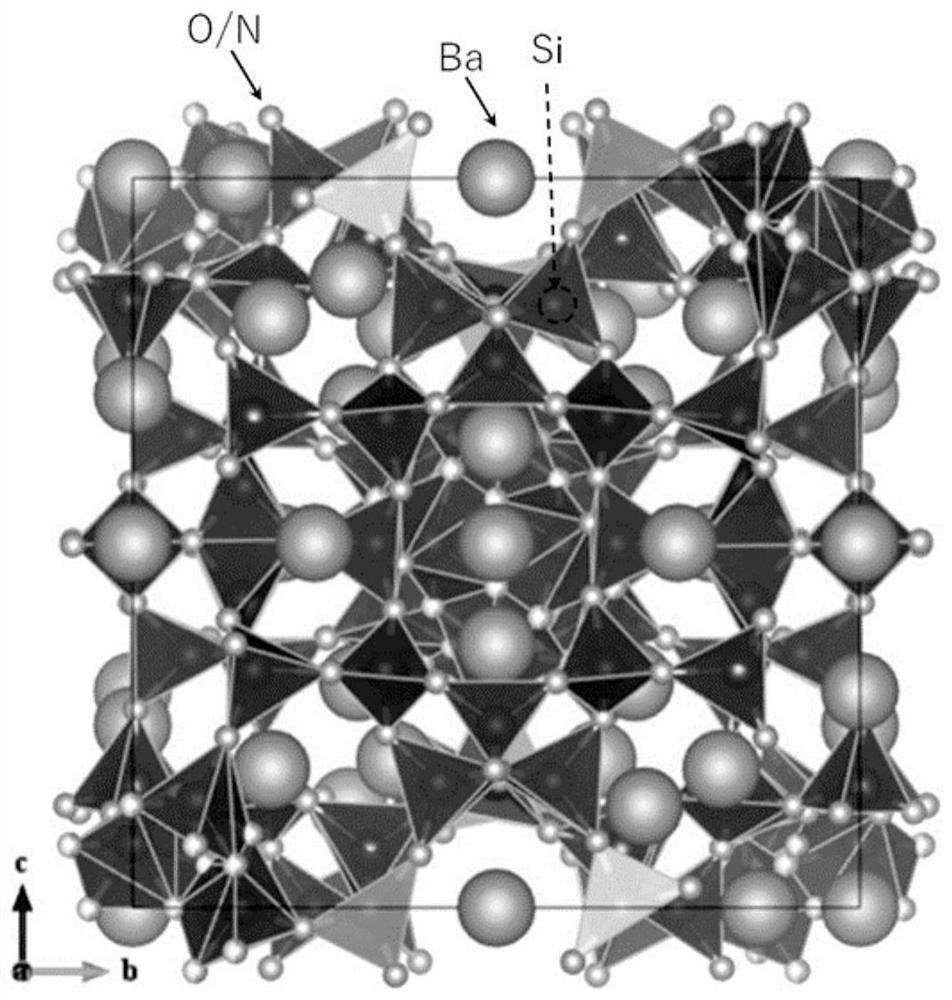

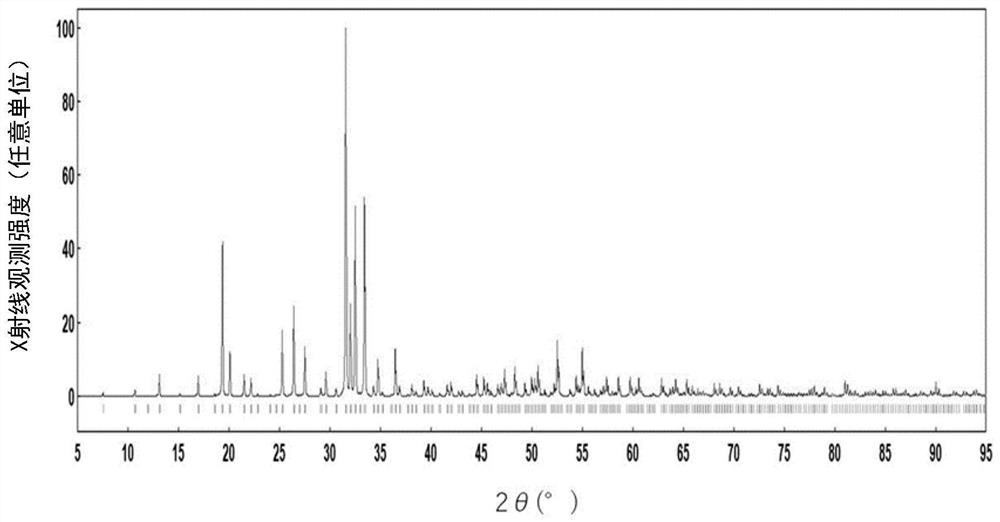

[0155] Next, synthesized with Ba 26 Si 51 o 2 N 84 Phosphors for host crystals. The raw material powder used has a specific surface area of 11.2m 2 Silicon nitride powder (SN-E10 grade manufactured by Ube Industries, Ltd.), silicon dioxide powder (SiO 2 ; manufactured by High Purity Chemical Research Institute), the purity of 99.7% of barium nitride (Ba 3 N 2 ; manufactured by Materion) and europium nitride (EuN; a product obtained by nitriding metal europium by heating it in an ammonia stream at 800° C. for 10 hours).

[0156] Design barium nitride (Ba 3 N 2 ), silicon nitride (Si 3 N 4 ), silicon oxide (SiO 2 ), the mixed composition of europium nitride (EuN) makes it (Ba, Eu) 26 Si 51 o 2 N 84 composition. The ratio of Ba to Eu is Eu / (Ba+Eu)=0.005. Weigh the raw powder to reach Ba 3 N 2 : 8.627, EuN: 0.130, Si 3 N 4 : 16.667, SiO 2 : 1 molar ratio, in a glove box with an oxygen content of 1 ppm in a nitrogen atmosphere...

Embodiment 2~8

[0164] [Examples 2 to 8: Phosphor]

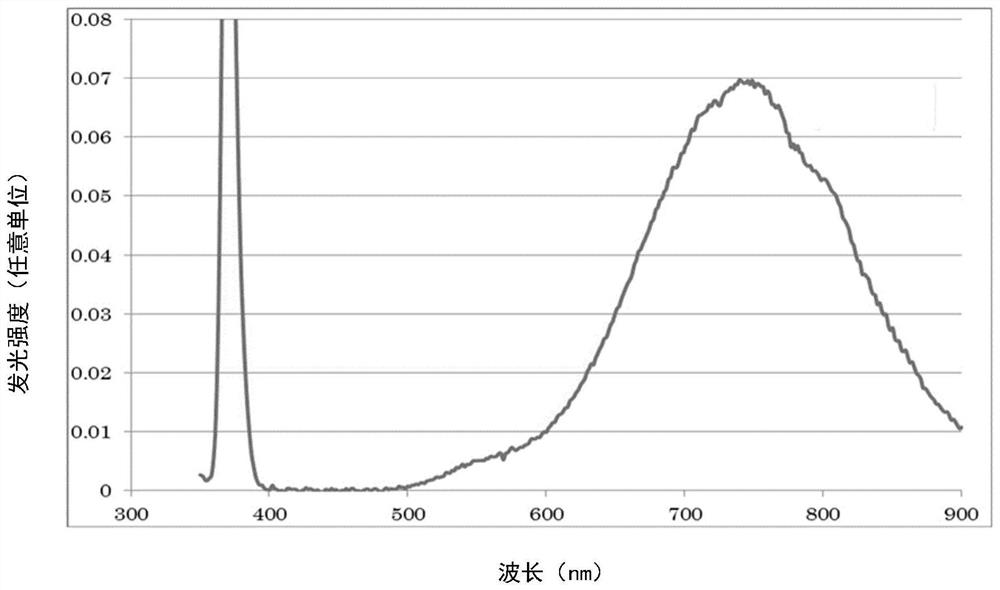

[0165] Using the same raw material powders as in Example 1, they were mixed with the composition shown in Table 2, and (Ba, Eu) were synthesized according to the same production method as in Example 1. 26 Si 51 (O, N) 86 Phosphor. Crystal grains were collected from the composite, and the crystalline phase was determined using a single crystal X-ray diffraction device. The results were confirmed to be the same as Ba shown in Table 1. 26 Si 51 o 2 N 84 same crystal structure. The emission spectrum was measured by microspectrometry while irradiating the particles with light of 360 nm. As shown in Table 2, the luminescence peak wavelength is red light to near infrared light.

[0166]

Embodiment 9~20

[0167] [Examples 9 to 20: Phosphor]

[0168] Using the same raw material powder as in Example 1, mixed with the composition shown in Table 3, and synthesized (A, M) according to the same production method as in Example 1 26 (D, E) 51 x 86 Phosphor. The composition of Table 3 sometimes deviates from (A, M) 26 (D, E) 51 x 86 , in which case a mixture of the same crystals with other phases is formed. Crystal grains were collected from the product, and the crystal phase was determined using a single crystal X-ray diffraction device. As a result, it was confirmed that Ba 26 Si 51 o 2 N 84 substances of the same crystal structure. While irradiating the particles with light of 360 nm, the emission spectrum was measured by microspectrometry. As shown in Table 3, the luminescence peak wavelength is red light to near infrared light.

[0169]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com