Anti-stress feed additive based on purification chelation process, and preparation method and application thereof

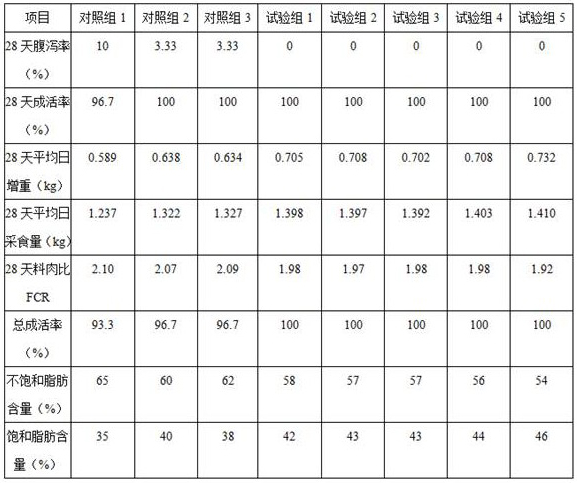

A feed additive and anti-stress technology, which is applied in the field of high-purity chitosan oligopotassium anti-stress feed additive and its preparation, can solve the problems of affecting acid-base balance, diarrhea of farmed animals, affecting palatability, etc., and achieves reduction of feed-to-meat ratio , reduce diarrhea rate, enhance the effect of activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

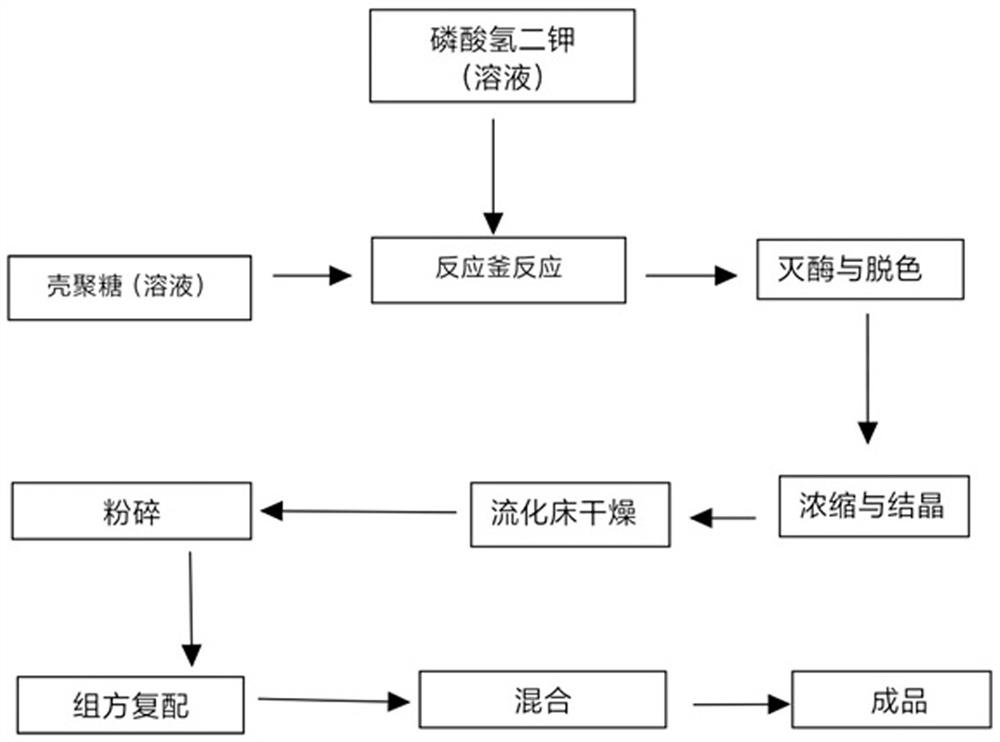

Method used

Image

Examples

Embodiment 1

[0041] An animal anti-stress feed additive, said additive comprises: chitosan oligosaccharide potassium, glucose oxidase, silicon dioxide, and the composition content of its additive is:

[0042] Potassium chitosan oligosaccharide 60 parts

[0043] Glucose oxidase 15 parts

[0044] Silica 5 parts

[0045]The potassium chitosan is obtained by an enzyme reaction; the specific steps of the enzyme reaction are: adding cellulase and glucose oxidase ( Add cellulase and glucose oxidase at one time, the mass ratio of the total amount of cellulase added to chitosan is 1:150, the mass ratio of the total amount of glucose oxidase added to chitosan oligosaccharide is 1:150), flow Add 15% dipotassium hydrogen phosphate solution (the solvent is water), the flow rate is 2 liters / min, and the feeding time is 2 hours to maintain the pH of the solution at 5.0-7.0 and maintain the temperature at 55±0.5°C. The ventilation volume is 1vvm, the tank pressure is maintained at 0.2-0.5MPa, the stirr...

Embodiment 2

[0048] An animal anti-stress feed additive, said additive comprises: chitosan oligosaccharide potassium, glucose oxidase, silicon dioxide, and the composition content of its additive is:

[0049] Potassium chitosan 80 parts

[0050] Glucose oxidase 15 parts

[0051] Silica 5 parts

[0052] The preparation steps of this example are the same as those of Example 1, and will not be described in detail here.

Embodiment 3

[0054] An animal anti-stress feed additive, the additive includes: chitosan oligosaccharide potassium, glucose oxidase, silicon dioxide, and the composition content of the additive is:

[0055] Potassium chitosan oligosaccharide 52 parts

[0056] Glucose oxidase 20 parts

[0057] Silicon dioxide 8 parts

[0058] The preparation steps of this example are the same as those of Example 1, and will not be described in detail here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com