Flame-retardant TPO (thermoplastic polyolefin) waterproof roll and preparation process thereof

A waterproof roll material and preparation technology, applied in the field of waterproofing, can solve problems such as poor mechanical fixation effect, and achieve the effects of ensuring weather resistance, reducing the probability of fire, and good flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

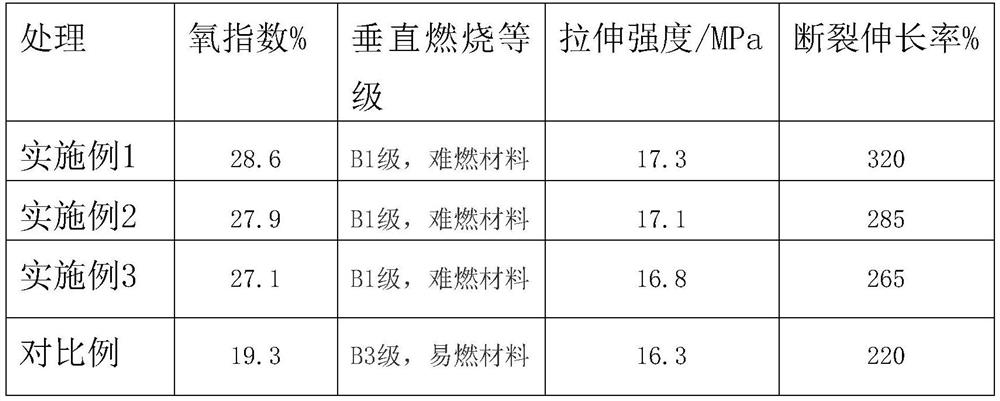

Examples

Embodiment 1

[0020] A flame-retardant TPO waterproof membrane, including the following components by mass: 20 parts of EPDM rubber, 30 parts of nitrile rubber, 15 parts of polypropylene (PP), 15 parts of high-density polyethylene (HDPE), hydrogen 5 parts of magnesium oxide, 10 parts of aluminum hydroxide, 5 parts of zinc borate, 15 parts of nano-calcium carbonate, 0.3 parts of antioxidant, 3 parts of defoamer, and 2 parts of clay.

[0021] The preparation method of the preparation process of the flame-retardant TPO waterproof coiled material comprises the following steps:

[0022] S1), the raw materials prepared according to the weight of the formula are mixed and put into the mixer, and then sent to the feeder, and then sent to the hot air dryer for drying, and the dried materials are transported to the feed buffer warehouse through the feeder ;

[0023] S2), after drying, the material is sent to a twin-screw extruder for melt plasticization and extrusion molding, and the extrusion tempe...

Embodiment 2

[0028] A flame-retardant TPO waterproof membrane, comprising the following components by mass: 20 parts of EPDM rubber, 20 parts of butyl rubber, 10 parts of polyethylene (PE), 10 parts of linear low-density polyethylene (LLDPE), 5 parts of magnesium carbonate hydrate, 5 parts of aluminum hydroxide, 5 parts of antimony trioxide, 10 parts of talc powder, 0.1 part of antioxidant, 2 parts of defoamer, and 1 part of clay.

[0029] The preparation method of the preparation process of the flame-retardant TPO waterproof coiled material comprises the following steps:

[0030] S1), the raw materials prepared according to the weight of the formula are mixed and put into the mixer, and then sent to the feeder, and then sent to the hot air dryer for drying, and the dried materials are transported to the feed buffer warehouse through the feeder ;

[0031] S2), after drying, the material is sent to a twin-screw extruder for melt plasticization and extrusion molding, and the extrusion tempe...

Embodiment 3

[0035] A flame-retardant TPO waterproof membrane, comprising the following components by mass: 30 parts of EPDM rubber, 30 parts of butyl rubber, 15 parts of polypropylene (PP), 20 parts of polyethylene (PE), decabromodi 10 parts of ethyl phenylene, 5 parts of aluminum hydroxide, 10 parts of antimony oxide, 25 parts of nano-calcium carbonate, 0.5 parts of antioxidant, 5 parts of defoamer, and 3 parts of clay.

[0036] The preparation method of the preparation process of the flame-retardant TPO waterproof coiled material comprises the following steps:

[0037] S1), the raw materials prepared according to the weight of the formula are mixed and put into the mixer, and then sent to the feeder, and then sent to the hot air dryer for drying, and the dried materials are transported to the feed buffer warehouse through the feeder ;

[0038] S2), after drying, the material is sent to a twin-screw extruder for melt plasticization and extrusion molding, and the extrusion temperature is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com