Nano-metal hole filling method adopting dry and wet mixed filling

A technology of mixed filling and nano-metal, which is applied in the direction of electrical connection and formation of printed components, can solve the problems of poor electrical and thermal conductivity, low density, low deep neck ratio, etc., and achieve strong thermal shock resistance, high density, The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

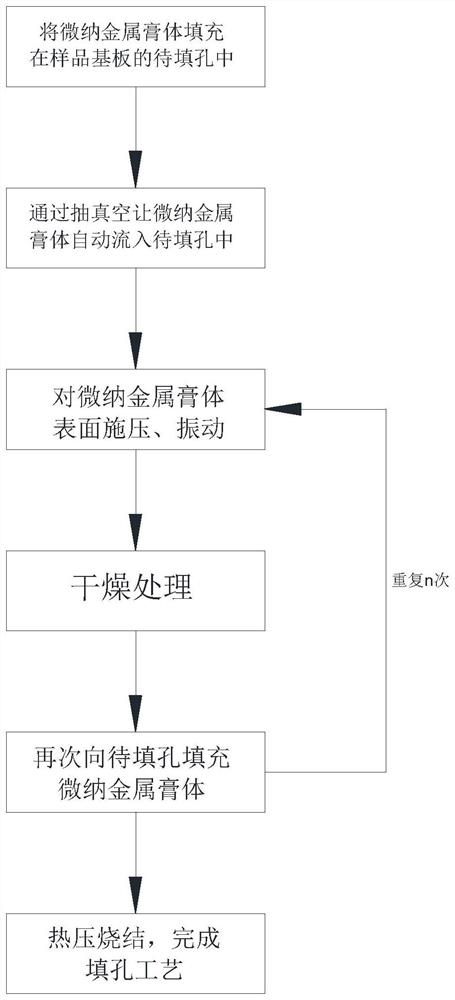

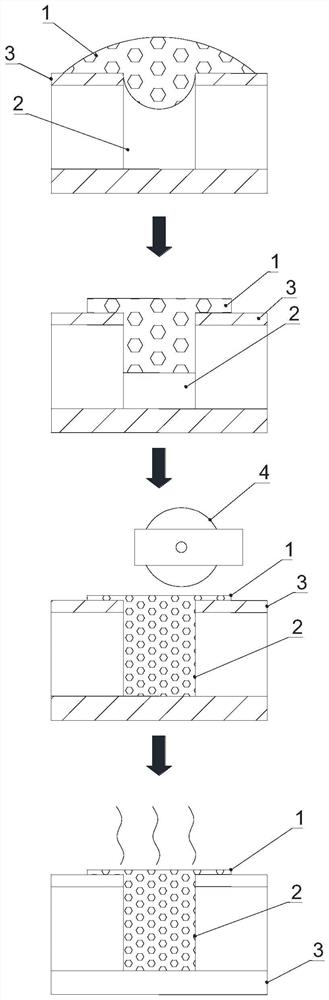

[0031] see Figure 1-Figure 3 , the present embodiment discloses a method for filling nano-metal holes with mixed dry and wet filling, including the following steps:

[0032] (1) Plasma cleaning is performed on the surface of the to-be-filled hole 2 of the sample substrate 3, so that the micro-nano metal paste is infiltrated with the sample substrate 3; then the micro-nano metal paste 1 is coated and filled on the to-be-filled hole 2 of the sample substrate 3 middle. Cleaning the to-be-filled holes 2 of the sample substrate 3 by a plasma cleaner is beneficial to improve the wettability of the surfaces of the to-be-filled holes 2 , so that the micro-nano metal paste 1 can more easily enter the to-be-filled holes 2 . The gases used include argon, hydrogen, nitrogen, oxygen, compressed air, carbon tetrafluoride, etc. The to-be-filled holes 2 described in this embodiment include through holes and blind holes.

[0033] (2) By vacuuming the to-be-filled hole 2 of the sample subst...

Embodiment 2

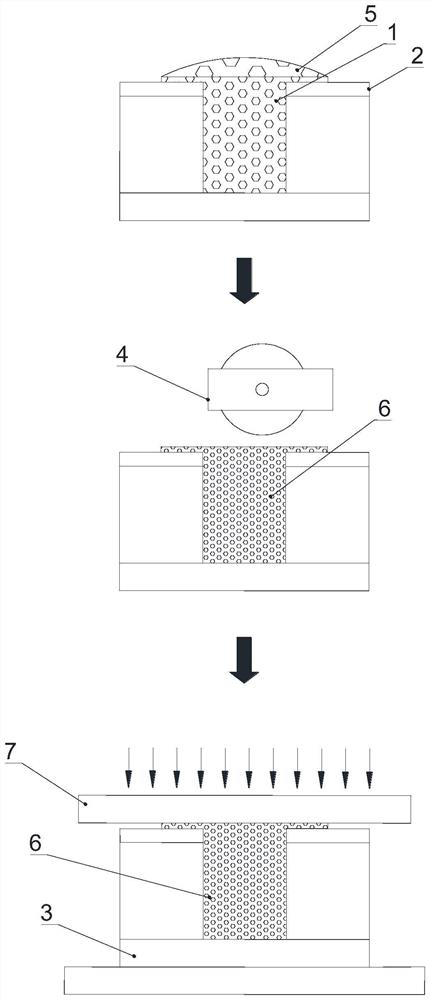

[0044] see Figure 4 , the present embodiment discloses another method for filling nano-metal holes with mixed dry and wet filling, which specifically includes the following steps:

[0045] (1) Plasma cleaning is performed on the surface of the sample substrate to be filled, so that the micro-nano metal paste is wetted with the sample substrate; then the micro-nano metal particles are solid coated and filled in the to-be-filled holes of the sample substrate.

[0046] (2) After the solid micro-nano metal particles completely fill the to-be-filled holes of the sample substrate, the solid surface of the micro-nano metal particles in the to-be-filled holes is treated, and then pressure is applied, and at the same time the micro-nano metal particles in the to-be-filled holes are applied. The solid vibrates, thereby realizing the compaction of the micro-nano metal particle solid in the hole to be filled.

[0047] (3) Adding a wetting medium, specifically a micro-nano metal paste, i...

Embodiment 3

[0051] The difference between this embodiment and Embodiment 2 is:

[0052] see Figure 5 , in step (3), adding a wetting medium to the to-be-filled hole of the sample substrate, the wetting medium is specifically a flux solution. Using the flux solution as a wetting medium will help reduce the surface tension and prevent metal oxidation while producing a wetting effect on the micro-nano metal particles, thereby improving the hot-pressing sintering effect in the later stage.

[0053] In this embodiment, the flux solution is composed of the following raw materials: 10%-30% of active agent, 10%-50% of film-forming agent, 1%-20% of surfactant and the remainder of solvent. Specifically, the active agents described in this embodiment are inorganic substances such as hydrochloric acid, hydrofluoric acid, orthophosphoric acid, stannous chloride, zinc chloride, ammonium chloride, potassium fluoride, and sodium fluoride, or rosin, hydrochloric acid, etc. Organic halides such as dimet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com