Preparation method of diamond neutron detector for eliminating polarization effect

A neutron detector and depolarization technology, which is applied in the measurement of neutron radiation, radiation measurement, instruments, etc., can solve the problems of detector performance degradation, improve charge collection efficiency, eliminate polarization effects, and improve Effects of Neutron Detection Efficiency and Count Rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

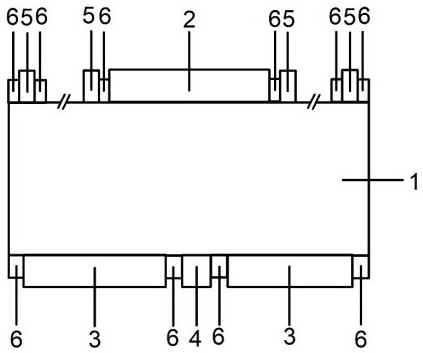

[0029] First, set the resistivity to 10 13 Ω·cm, the nitrogen content is less than 1ppb, and the thickness is 100μm. The diamond body material 1 is first placed in a nitrogen quartz furnace at 600°C for 20 minutes, and then placed in HNO in a water bath at 120°C. 3 :H 2 SO 4 :HClO 4 = Boiling in a 1:1:1 mixed solution for 40 minutes to remove carbides on the diamond surface; ultrasonically cleaning the diamond body material for 5 minutes with acetone, isopropanol, and deionized water, and then using 80°C hot deionized water and Rinse 5 times at intervals with deionized water at room temperature to remove the contamination of organic matter on the diamond surface, and then dry it with 99.99% high-purity nitrogen gas; put the dried diamond body material into the plasma surface treatment equipment for plasma surface cleaning, and the power of the plasma is 20W, the time is 10 minutes ( figure 2 ).

[0030] Secondly, put the treated diamond body material into the chemical va...

Embodiment 2

[0035] First, set the resistivity to 10 13 Ω·cm, the nitrogen content is less than 1ppb, and the thickness is 100μm. The diamond body material 1 is first placed in a nitrogen quartz furnace at 600°C for 20 minutes, and then placed in HNO in a water bath at 120°C. 3 :H 2 SO 4 :HClO 4 = Boiling in a 1:1:1 mixed solution for 40 minutes to remove carbides on the diamond surface; ultrasonically cleaning the diamond body material for 5 minutes with acetone, isopropanol, and deionized water, and then using 80°C hot deionized water and Rinse 5 times at intervals with deionized water at room temperature to remove the contamination of organic matter on the diamond surface, and dry it with high-purity nitrogen; put the dried diamond body material into the plasma surface treatment equipment for plasma surface cleaning, and the power of the plasma is 20W , with a time of 10 minutes ( figure 2 ).

[0036] Secondly, put the treated diamond body material into the chemical vapor depositi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com