Method for preparing N, N-diisopropylethylamine

A technology for diisopropylethylamine and diisopropylamine, which is applied in the field of preparing N,N-diisopropylethylamine, can solve the problems of high waste water treatment cost, high stirring requirements, equipment corrosiveness, etc. Low requirements, good selectivity, and the effect of avoiding corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0064] 1. The preparation process of the catalyst: Al(OH)3 is prepared into sodium metaaluminate solution with 40% NaOH, and the precipitate is neutralized with nitric acid. After aging, filtering and washing, it is rolled into a ball, dried and roasted to obtain a diameter of 3mm. The spherical Al2O3 carrier, the nitrates of Mo, Ni, and Cu are made into a mixed solution in proportion, the Al2O3 carrier is impregnated, dried and placed in a muffle furnace for 6 h at 490°C, and mixed with Mo, Ni, and Cu nitrates again after cooling Solution impregnated, after roasting under the same conditions, the prepared content is Mo8%, Ni25%, Cu5%, and the rest is Al2O3 Mo-Ni-Cu / Al2O3 catalyst, after the catalyst is loaded into the reactor, use pure hydrogen at 0.05MPa pressure, The finished catalyst was obtained by reduction for 24 hours at a temperature of 460°C and a space velocity of 1000h-1;

[0065] 2. The reaction conditions are reaction pressure: 0.8-1.6Mpa, hydrogen is used to mai...

Embodiment 1

[0070] Reaction conditions: Reaction pressure: 0.8Mpa, reaction temperature: 180°C, raw materials are ethanol and diisopropylamine to form a mixed solution with a molar ratio of 1.2:1.

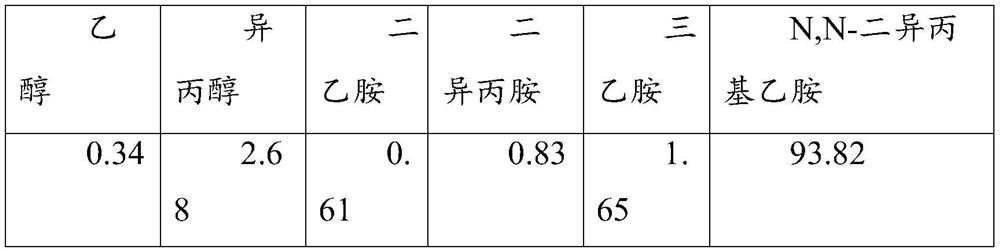

[0071] The experimental data are:

[0072]

Embodiment 2

[0074] Reaction conditions: Reaction pressure: 0.8Mpa, reaction temperature: 200°C, raw materials are ethanol and diisopropylamine to form a mixed solution with a molar ratio of 1.2:1.

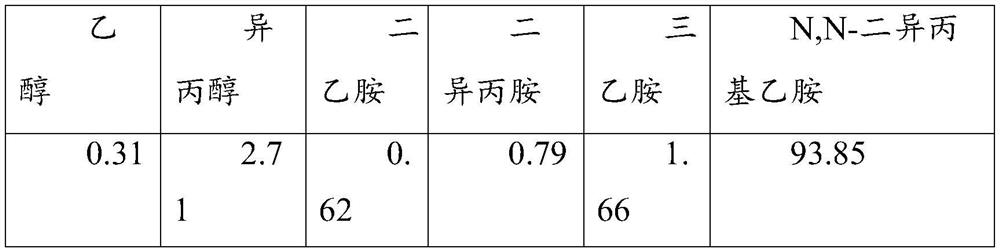

[0075] The experimental data are:

[0076]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com