Calixarene porous polymer with ultra-high removal rate and ultra-high adsorption capacity and application of calixarene porous polymer to selective separation of dyes

A porous polymer, adsorption capacity technology, applied in the fields of alkali metal compounds, adsorption of water/sewage treatment, water pollutants, etc., can solve the problems of thermal instability, limited development of calixarene-based POPs, low adsorption rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

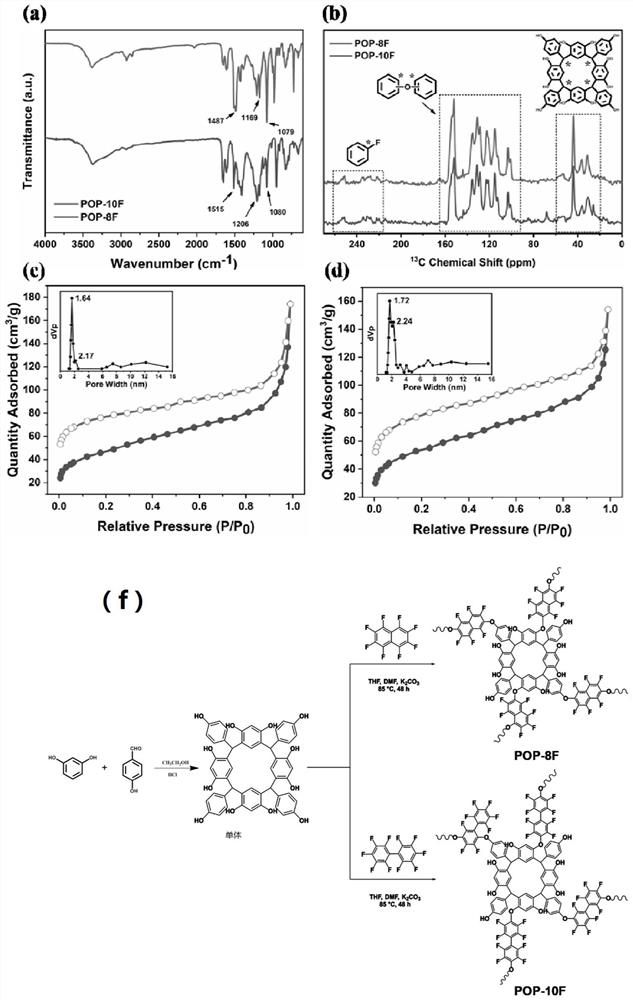

[0031] Synthesis of monomer: Pour resorcinol (0.55 g, 5 mmol) and absolute ethanol (25 mL) into a 200 mL flask, then add concentrated hydrochloric acid (3.5 mL, 12 M, Adding time is 10 minutes), then dissolve p-hydroxybenzaldehyde (0.61g, 5mmol) in 10mL of absolute ethanol, and add dropwise to the above reaction system in 5 minutes. After dropping, remove the ice bath, and heat to reflux for 12 hours while stirring conventionally. After the reaction was completed, the mixture was cooled to room temperature and filtered, and then the filter cake was washed with anhydrous methanol, acetone and ether and dried under vacuum at 60°C to obtain a monomer with a yield of 40%. The structural formula is shown in figure 1 f. 1 H NMR (400MHz, DMSO- d 6 , ppm): δ 7.78 (s, 1H), 7.38 (s, 2H), 5.58 (d, J = 7.6 Hz, 2H),5.41 (dd, J = 21.1, 13.4 Hz , 3H), 5.02 (s, 1H ), 4.46 (s, 1H).

[0032] Synthesis of POP-10F: The monomer (0.3 g, 0.35 mmol), potassium carbonate (0.41 g, 3 mmol) and anhy...

Embodiment 2

[0038] Example 2 Adsorption Kinetics

[0039] In the experiment, 15 mg of POP-8F or POP-10F was added to the dye solution (50 ppm, 30 mL), and then the mixture was stirred at room temperature at a rate of 600 rpm. At various time intervals, 3 mL of the solution was withdrawn and filtered through a 0.22 μm syringe filter to monitor the adsorption process. The UV-Vis spectrum of the filtrate was analyzed by a UV-Vis spectrophotometer, and the change of the maximum absorbance intensity was recorded to further analyze the adsorption kinetics. Adsorption kinetics were analyzed using pseudo-first-order and pseudo-second-order kinetic models.

[0040] Pseudo-first-order kinetic model:

[0041] Pseudo-second-order kinetic model:

[0042] where q e (mg g -1 ) is the equilibrium adsorption capacity; q t (mg g -1 ) is the adsorption capacity, the unit is t (min); k 1 (min -1 ) and k 2 (g mg -1 min -1 ) are constants for the pseudo-first-order and pseudo-second-order ...

Embodiment 3

[0047] Embodiment 3 adsorption thermodynamics

[0048] To evaluate the maximum adsorption capacity of POP-8F and POP-10F for different dyes, adsorption isotherm experiments were performed. In the test, 5 mg of adsorbent was added to 15 mL of dye solution and stirred until adsorption equilibrium was reached. UV-Vis spectrophotometry was then performed, and the dye concentration was calculated from the change in maximum absorbance intensity. Adsorption capacity (q e , mg g -1 ) is calculated according to the following formula:

[0049]

[0050] where C i and C e (mg L -1 ) is the initial concentration and final concentration of the target pollutant, m (g) is the weight of the adsorbent used in the adsorption experiment, and V (L) is the volume of the target pollutant solution.

[0051] The Langmuir adsorption isotherm model was used in this experiment.

[0052]

[0053] where q e (mg g -1 ) is the equilibrium adsorption capacity; K L is a constant of the Lang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com