Titanium oxynitride film pressure sensor and manufacturing method thereof

A technology of titanium oxynitride and a manufacturing method, which is applied in the directions of instruments, measuring force, ion implantation and plating, etc., can solve the large difference in the proportion of composition content uniformity, the deterioration of film density and roughness, and the dispersion of sensor batch performance. Large and other problems, to achieve the effect of good performance consistency, good compactness, and high long-term work stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A method for manufacturing a titanium oxynitride film pressure sensor, comprising the following steps:

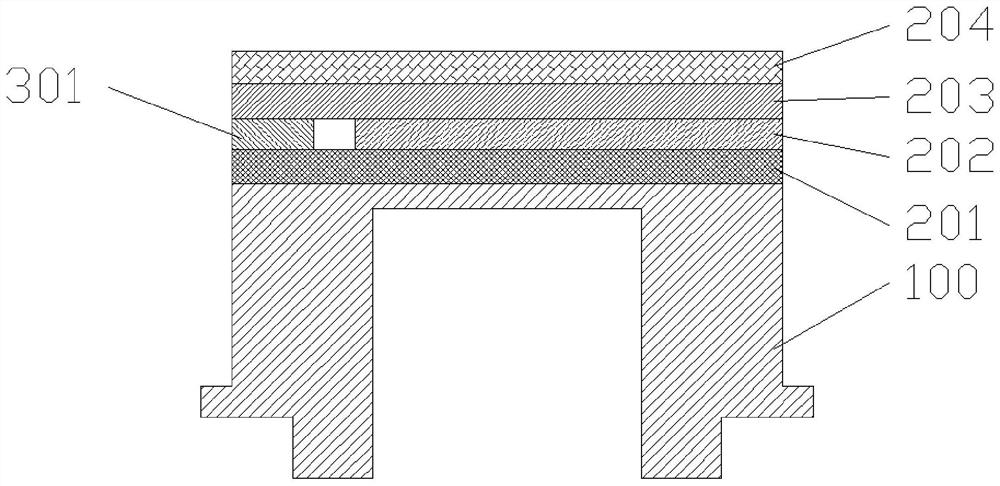

[0038]S1. On the surface of the elastic element 100, perform mirror treatment by grinding and polishing methods, and deposit an insulating film 201 (2-6um silicon oxide film) on the surface of the elastic element 100 by magnetron sputtering film deposition technology. In the present invention, the elastic element 100 used may be a stainless steel elastic substrate, but is not limited thereto.

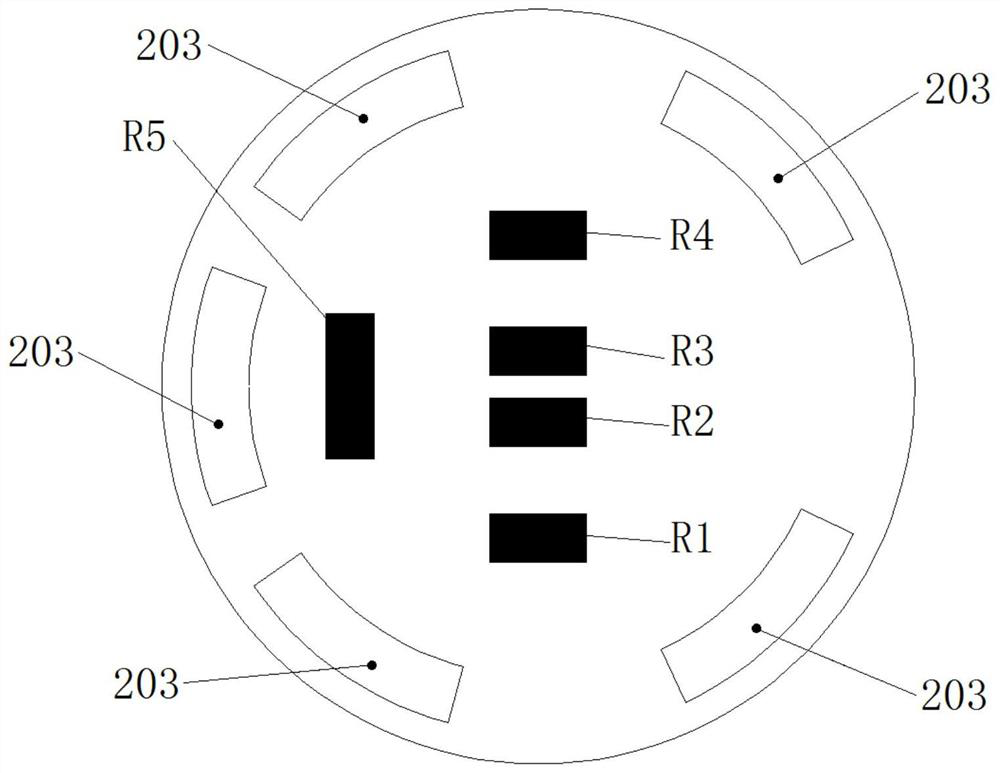

[0039] S2. In the strained region (middle region) of the insulating film 201, using titanium nitride as the target material, a titanium nitride oxide film 202 is deposited on the insulating film 201 by a vacuum sputtering method, specifically: first, the surface of the titanium nitride is treated Sputtering cleaning, removing impurities and pollutants on the surface of the target, and then introducing oxygen into the vacuum chamber to react with the sputtered titanium nitride ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com