Omeprazole enteric-coated pellet and preparation process thereof

An omeprazole intestinal and preparation technology technology, which is applied in the directions of microcapsules, medical preparations with non-active ingredients, and medical preparations containing active ingredients, etc. Influence, low yield of industrialized production, etc., to achieve the effect of smooth and round appearance, controllable product quality, and reduction of broken fine powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

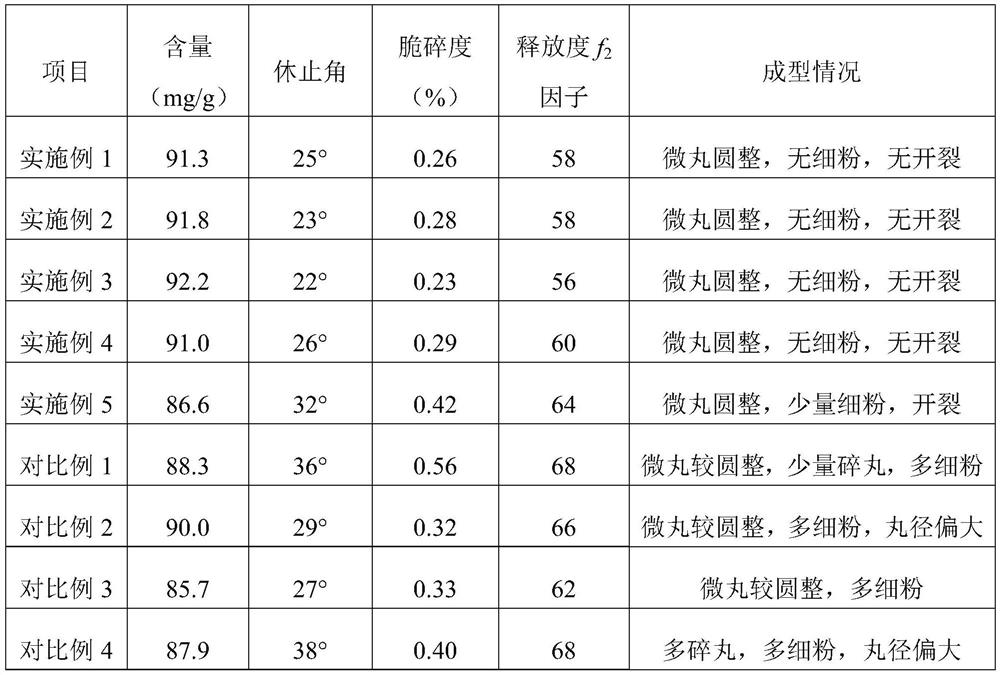

Examples

Embodiment 1

[0028] A preparation process for omeprazole enteric-coated pellets, comprising the steps of:

[0029] (1) Slow-release protective solution: Mix the modified polylactic acid solution and ethyl cellulose aqueous dispersion, and stir at 20°C for 50 minutes to obtain the slow-release protective solution;

[0030] (2) Mannitol solution: mannitol is dissolved in purified water to obtain a mannitol solution;

[0031] (3) Ball core: Dry mix omeprazole and microcrystalline cellulose for 10 minutes, add simethicone, and cut at 2000r / min for 12 minutes to obtain a wet and soft material, which is put into an extrusion spheronizer to prepare Granules, with 400r / min, time is 2min, get ball core;

[0032] (4) Coated ball core: Preheat the fluidized bed, pour the ball core into the multi-functional fluidized bed, set the coating operating conditions as the rotating speed is 50r / min, the fan frequency is 35Hz, and the air inlet temperature is 33°C , turn on the blower to preheat the pellet c...

Embodiment 2

[0035] A preparation process for omeprazole enteric-coated pellets, comprising the steps of:

[0036] (1) Slow-release protective solution: mix the modified polylactic acid solution and ethyl cellulose aqueous dispersion, and stir at 30°C for 60 minutes to obtain the slow-release protective solution;

[0037] (2) Mannitol solution: mannitol is dissolved in purified water to obtain a mannitol solution;

[0038] (3) Ball core: Dry mix omeprazole and microcrystalline cellulose for 10-15 minutes, add simethicone, cut at 3000r / min for 15 minutes to obtain wet and soft material, put the wet and soft material into the extrusion spheronizer Carry out granulation, with 500r / min, time is 3min, obtains ball core;

[0039](4) Coated ball core: Preheat the fluidized bed, pour the ball core into the multi-functional fluidized bed, set the coating operation conditions as the rotating speed is 60r / min, the fan frequency is 45Hz, and the air inlet temperature is 40°C , turn on the blower to ...

Embodiment 3

[0042] A preparation process for omeprazole enteric-coated pellets, comprising the steps of:

[0043] (1) Slow-release protective solution: mix the modified polylactic acid solution and ethyl cellulose aqueous dispersion, and stir at 25°C for 55 minutes to obtain the slow-release protective solution;

[0044] (2) Mannitol solution: mannitol is dissolved in purified water to obtain a mannitol solution;

[0045] (3) Ball core: Dry mix omeprazole and microcrystalline cellulose for 12 minutes, add simethicone, and cut at 2500r / min for 15 minutes to obtain a wet and soft material, which is put into an extrusion spheronizer to prepare Granules, with 450r / min, the time is 2min, get ball core;

[0046] (4) Coated ball core: Preheat the fluidized bed, pour the ball core into the multi-functional fluidized bed, set the coating operation conditions as the speed is 55r / min, the fan frequency is 40Hz, and the air inlet temperature is 36°C , turn on the blower to preheat the pellet core, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com