Absorbable biological membrane, preparation method and application thereof

A biofilm and derivative technology, applied in the field of medical devices, can solve the problems of membrane exposure and infection retention time, and achieve the effects of controllable degradation, improved bone quality, and strong mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

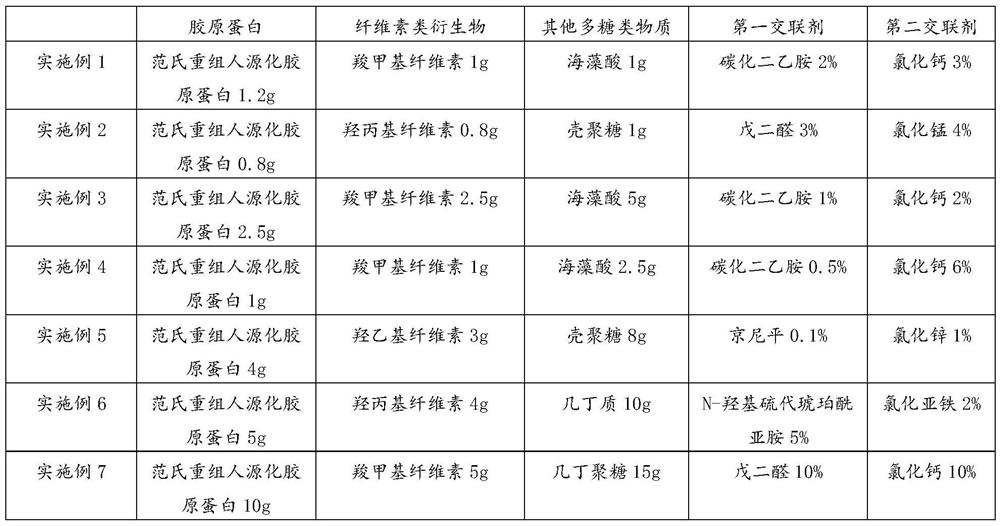

[0077]The preparation of embodiment 1 absorbable biofilm

[0078] (1) Weigh 1 g of carboxymethyl cellulose and 1 g of alginic acid respectively, add 50 ml of water for injection, and swell overnight to form a solution.

[0079] (2) Weigh 1.2g of Fan's recombinant humanized collagen, add 50ml of water for injection to dissolve, add all of it to the above-mentioned solution A, and continue stirring and dispersing at 45°C for 0.5h at a stirring speed of 100 rpm. Get the mixed solution, then fill the mixed solution into the mold, put it in the refrigerator at 2-8°C for 10 hours, then transfer it to the refrigerator for freezing, the freezing temperature is -80°C, the freezing time is 2 hours, and then put it in the freeze dryer Drying for 28 hours yielded a lyophilized product.

[0080] (3) Soak the above freeze-dried product in a concentration of 2% carbodiethylamine for cross-linking for 30 hours, then transfer to a concentration of 3% calcium chloride and soak for 2 hours for ...

Embodiment 2

[0081] The preparation of embodiment 2 absorbable biofilm

[0082] (1) Weigh 0.8 g of hydroxypropyl cellulose and 1 g of chitosan, add 50 ml of water for injection and swell overnight to form a solution.

[0083] (2) Weigh 0.8g of Fan's recombinant humanized collagen, add 50ml of water for injection to dissolve, add all of it to the above-mentioned solution A, continue stirring and dispersing at 40°C for 0.6h, and the stirring speed is 120 rpm, Get the mixed solution, then fill the mixed solution into the mold, put it in the refrigerator at 2-8°C for 12 hours, then transfer it to the refrigerator for freezing, the freezing temperature is -80°C, the freezing time is 2 hours, and then put it in the freeze dryer After drying for 30 hours, a lyophilized product was obtained.

[0084] (3) Soak the above-mentioned lyophilized product in glutaraldehyde with a concentration of 3% for cross-linking for 30 hours, then transfer to a concentration of 4% manganese chloride and soak for 3 ...

Embodiment 3-21

[0085] Preparation of embodiment 3-21 absorbable biofilm

[0086] Examples 3-21 used the amount of raw materials described in Table 2, and used the method described in Example 1 to prepare absorbable biofilms.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com