Monovalent ion selective cation exchange membrane as well as preparation method and application thereof

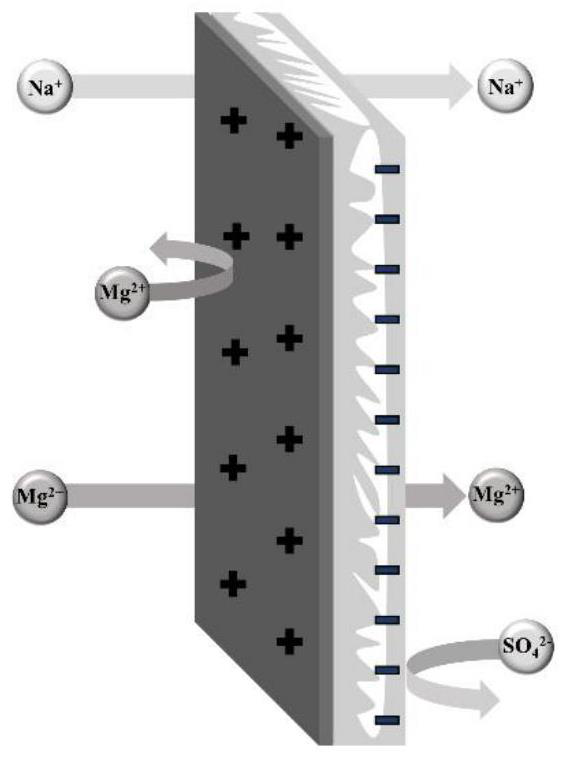

A cation exchange membrane, ion selectivity technology, applied in cation exchange, ion exchange, chemical instruments and methods, etc., can solve the problem of high membrane resistance, achieve small membrane resistance, high monovalent ion permeation flux, reduce reaction the effect of penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

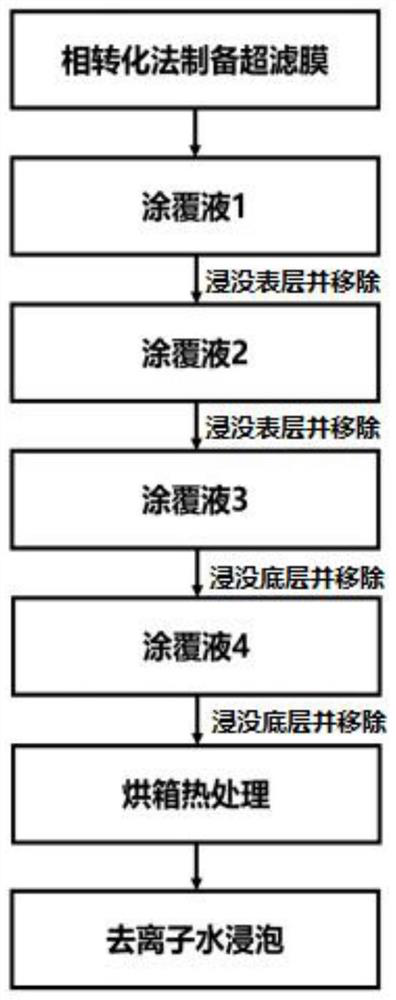

[0041]In the present invention, the preparation method of the polysulfone-based membrane preferably includes the following steps:

[0042] The casting liquid is subjected to phase inversion to obtain the polysulfone-based membrane, the casting liquid includes polyethersulfone, sulfonated polysulfone and polar organic solvent, and the polyethersulfone and sulfonated polysulfone in the casting liquid The total mass percentage is 18~28%.

[0043] In the present invention, the casting solution includes a polar organic solvent. In the present invention, the polar organic solvent preferably includes N,N-dimethylformamide, N,N-dimethylacetamide and N - one or more of methylpyrrolidone.

[0044] In the present invention, in the casting solution, the total mass percentage of polyethersulfone and sulfonated polysulfone is preferably 18-28%, preferably 20-25%.

[0045] In the present invention, before the phase inversion, the present invention preferably carries out defoaming treatment...

Embodiment 1

[0102] according to figure 1 The process flow shown, to image 3 In the experimental equipment shown, polyethersulfone, sulfonated polysulfone (sulfonated degree of 20%) and dissolved N,N-dimethylformamide are mixed to obtain a casting solution, wherein polyethersulfone and sulfonated polysulfone The total mass percentage of sulfone is 23wt.%, the proportion of sulfonated polysulfone to the total mass of polyethersulfone and sulfonated polysulfone is 10%, the casting solution is defoamed for 12 hours, and the phase inversion is carried out under the condition of 20% air humidity for 24 hours , to obtain polysulfone base membrane;

[0103] Aqueous tannic acid solution with a mass percentage of 0.1wt.% was used as coating solution 1 to immerse the dense surface layer of the polysulfone-based membrane, and surface treated it for 10 minutes;

[0104] Remove the coating solution 1 and blow dry the surface of the film until it is clean and dry;

[0105] Continuing to immerse the ...

Embodiment 2

[0116] according to figure 1 In the process flow shown, polyethersulfone, sulfonated polysulfone (32% sulfonated degree) and dissolved N,N-dimethylformamide are mixed to obtain a casting solution, wherein polyethersulfone and sulfonated polysulfone The total mass percentage of sulfone is 20wt.%, the proportion of sulfonated polysulfone to the total mass of polyethersulfone and sulfonated polysulfone is 20%, the casting solution is defoamed for 18 hours, and the phase inversion is carried out under the condition of 30% air humidity for 28 hours , to obtain polysulfone base membrane;

[0117] The 3,4-dihydroxybenzoic acid aqueous solution with a mass percentage of 0.2wt.% is used as the coating solution 1 to immerse the dense surface layer surface of the polysulfone-based membrane, and it is surface-treated for 5 minutes;

[0118] Remove the coating solution 1 and blow dry the surface of the film until it is clean and dry;

[0119] Continuing to immerse the dense surface layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| Degree of sulfonation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com