A kind of organophosphoric acid modified tio 2 Preparation method of /pvc blended cation exchange membrane and its application in electrodialysis

A cation exchange membrane and cation exchange technology, applied in the field of membrane science, can solve the problems of high energy consumption and low current efficiency, and achieve the effects of low energy consumption, reduced membrane surface resistance, improved ion selectivity and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

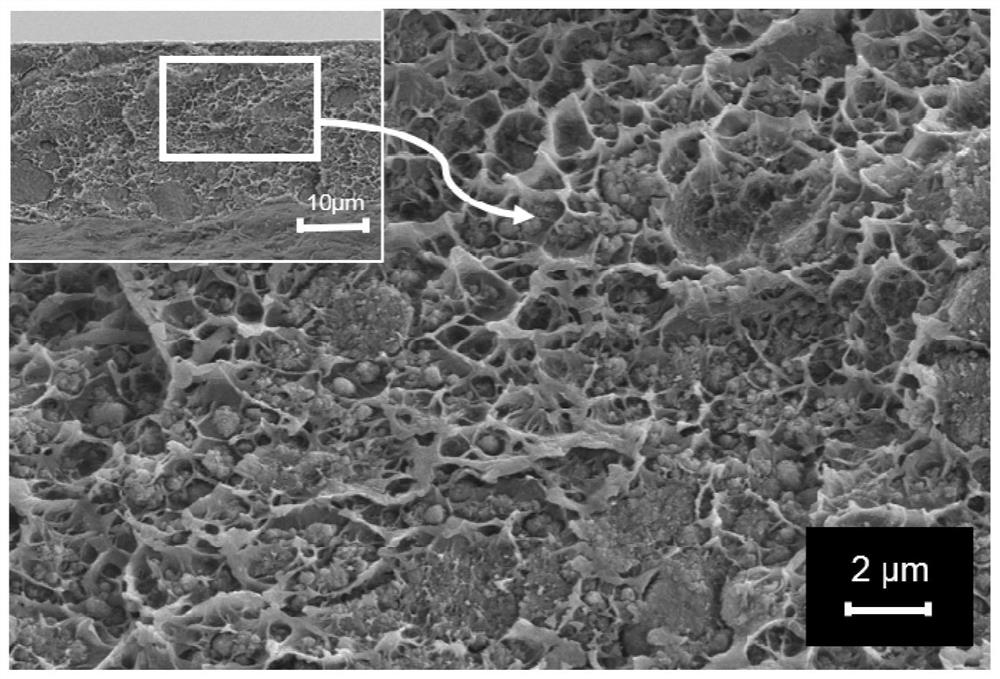

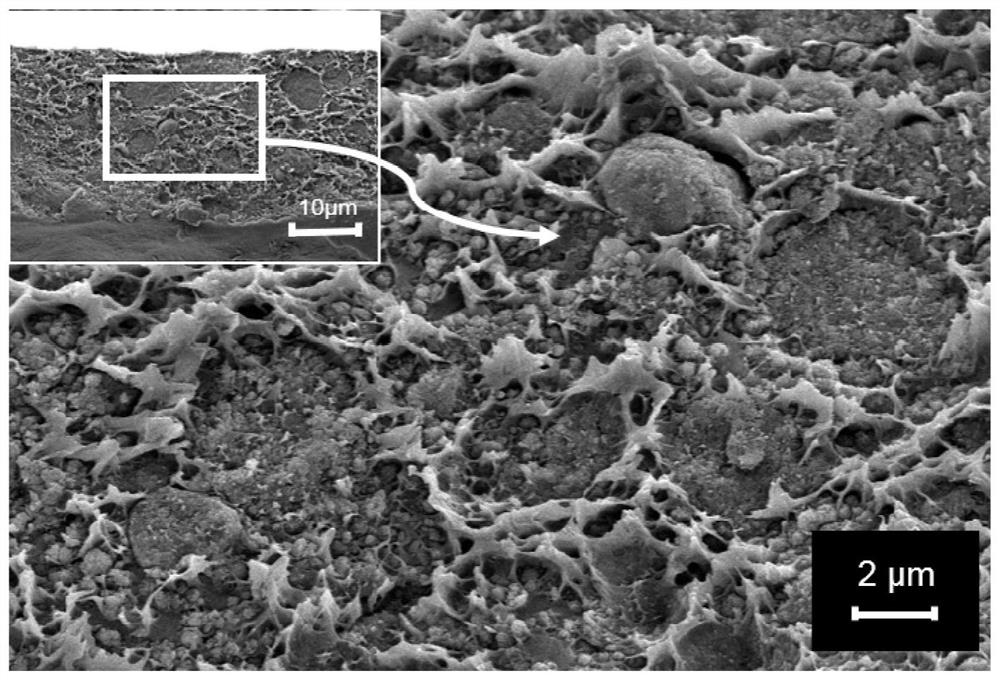

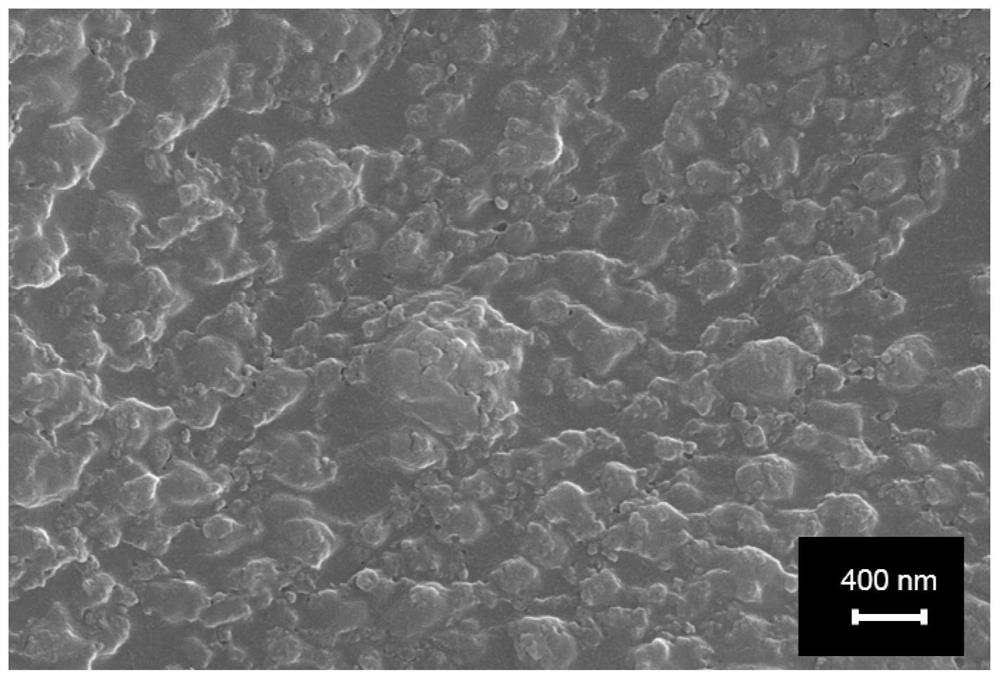

[0031] Disperse the cation exchange resin in N,N-dimethylacetamide, then dissolve polyvinyl chloride in it, put it into an air bath shaker and oscillate evenly to obtain a casting solution. The mass percent of each component in the casting solution is 85% of solvent, 10.5% of PVC, and 4.5% of cation exchange resin. Ultrasonic defoaming treatment of the configured casting solution for a period of time, the casting solution is poured and scraped on a smooth flat plate to form a film, then placed in a vacuum drying oven, dried at 60°C for 24 hours, and then the film is taken out of the oven and cooled in the air to room temperature. The cooled film was put into deionized water for 12 hours, and the film peeled off automatically from the smooth flat plate, and was soaked in 1 mol / L NaCl solution for 12 hours, and the film was marked as mem-0. tested as Figure 5 , 6 As shown, the surface resistance of the cationic membrane is 34Ω·cm 2 , and its electrodialysis experimental ene...

Embodiment 2

[0033] First measure 100mL of 50wt.% aminotrimethylene phosphonic acid aqueous solution, dilute it with deionized water to 25wt.% aminotrimethylene phosphonic acid aqueous solution; weigh 1g TiO 2 Place in 200mL of 25wt.% aminotrimethylene phosphonic acid aqueous solution, place it in a magnetic stirrer at room temperature and stir vigorously for 12h, then centrifuge; the product is washed repeatedly with deionized water until the pH of the washing solution is neutral; finally, the The product was placed in a vacuum drying oven and dried at 80°C for 24 hours; the organophosphorylated TiO 2 .

[0034] Disperse the cation exchange resin in N,N-dimethylacetamide, dissolve polyvinyl chloride in it, and then modify the TiO with organic phosphoric acid 2 Disperse in it, put it into an air bath shaker and vibrate evenly to obtain a casting solution. The mass percentage of each component in the casting solution is solvent 84.85%, PVC 10.5%, cation exchange resin 4.5%, organic phosph...

Embodiment 3

[0036] Disperse the cation exchange resin in N,N-dimethylacetamide, dissolve polyvinyl chloride in it, and then modify the TiO with organic phosphoric acid 2 Dispersed in it (organophosphoric acid modified TiO 2 The preparation is the same as in Example 2), put into an air bath shaker and vibrate evenly to obtain the casting solution. The mass percentage of each component in the casting solution is solvent 84.70%, PVC 10.5%, cation exchange resin 4.5%, organic phosphoric acid modified TiO 2 0.3% where modified TiO 2 The mass accounts for 2% of the total mass of PVC and resin. Ultrasonic defoaming treatment of the configured casting solution for a period of time, the casting solution is poured and scraped on a smooth flat plate to form a film, then placed in a vacuum drying oven, dried at 60°C for 24 hours, and then the film is taken out of the oven and cooled in the air to room temperature. The cooled membrane was put into deionized water for 12 hours, and the membrane pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface resistance | aaaaa | aaaaa |

| surface resistance | aaaaa | aaaaa |

| surface resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com