Ozone-hydrogen peroxide catalytic oxidation catalyst and method for treating biochemical wastewater by using ozone-hydrogen peroxide catalytic oxidation catalyst

A hydrogen peroxide and catalytic oxidation technology, which is applied in the direction of oxidized water/sewage treatment, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as difficult recovery, easy loss of metal ions, poor catalyst stability, etc., and achieve improvement Effects of mechanical strength and specific surface area, enhanced catalytic oxidation efficiency, and improved catalytic oxidation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

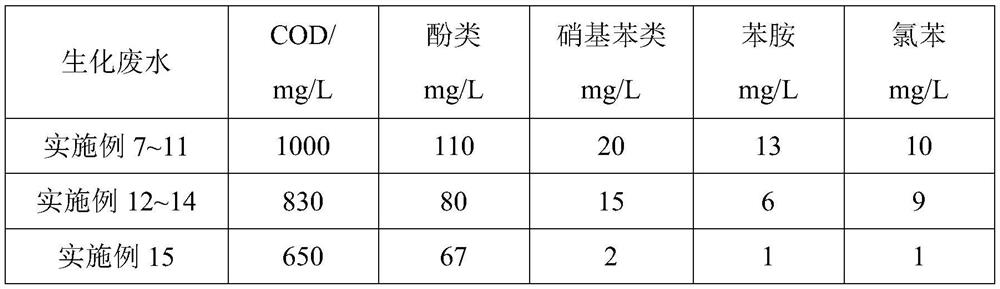

Examples

Embodiment 1-1

[0063] Example 1-1: Modified Kaolin, α-Silicon Carbide and TiO 2 Preparation of composite carrier-1

[0064] Take Kaolin, α-Silicon Carbide and TiO 2 60g of the compound mixed according to the mass ratio of 3:1:1 was placed in 600g of ethanol, mixed and stirred for 10 minutes, mixed and pulverized by a high-shear emulsifier for 40 minutes, filtered and then placed in a constant temperature drying box to dry at 100 °C for 3 hours, and then the obtained The mixed powder was calcined at 750 °C for 2 h in a muffle furnace to obtain modified kaolin, α-silicon carbide and TiO 2 composite carrier.

Embodiment 1-2

[0065] Example 1-2: Modified Kaolin, α-Silicon Carbide and TiO 2 Preparation of composite carrier-2

[0066] Take Kaolin, α-Silicon Carbide and TiO 2 20g of the compound mixed according to the mass ratio of 5:3:1 was placed in 150g of methanol, mixed and stirred for 5 minutes, mixed and pulverized by a high shear emulsifier for 20 minutes, filtered and then placed in a constant temperature drying box to dry at 90 °C for 4 hours, and then the obtained The mixed powder was calcined at 600 °C for 3 h in a muffle furnace to obtain modified kaolin, α-silicon carbide and TiO 2 Composite carrier-2.

Embodiment 1-3

[0067] Examples 1-3: Modified Kaolin, α-Silicon Carbide and TiO 2 Preparation of composite carrier-3

[0068] Take Kaolin, α-Silicon Carbide and TiO 2 20g of the compound mixed according to the mass ratio of 1:2:1 was placed in 100g of ethanol, mixed and stirred for 10 minutes, mixed and pulverized by a high shear emulsifier for 60 minutes, filtered and then placed in a constant temperature drying box and dried at 120 ° C for 2 hours, and then the obtained The mixed powder was calcined at 800 °C for 1 h in a muffle furnace to obtain modified kaolin, α-silicon carbide and TiO 2 Composite carrier-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com