Anti-static polyester film and preparation method thereof

A polyester film, anti-static technology, applied in the direction of conductive coatings, coatings, epoxy resin coatings, etc., can solve problems such as agglomeration, affecting the adhesion of coatings and functional coatings, and easy entanglement. Achieve the effects of reducing intertwining and lapping, excellent chemical stability, and increasing crosslinking density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

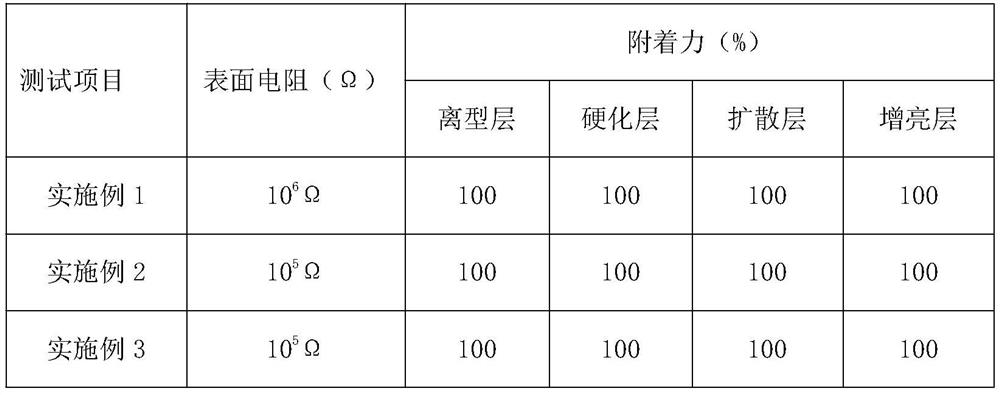

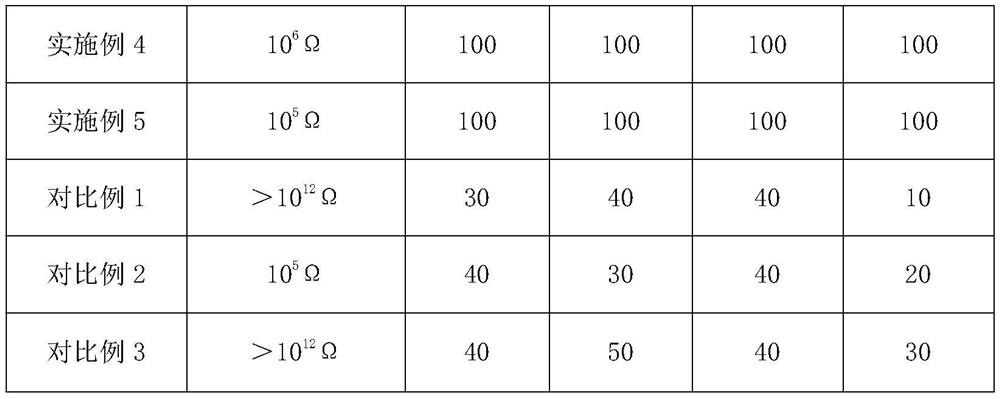

Embodiment 1

[0043] Preparation of modified acrylic resin emulsion:

[0044] Acrylic acid, NN'-dimethelamine is added to the reactor, phenol, ethanol, epoxy resin, stirred at 80 ° C for 1 hour, the rotational speed is 700 rpm, and then the reaction kettle temperature is increased to 105 ° C, stirring reaction for 3 hours, and then administered to the reactor, and an appropriate amount of distilled water was added, stirred at a rate of 1800 rpm, stirred at a rate of 1800 rpm, and the emulsified reaction was 3 hours to obtain a modified acrylic resin emulsion. .

[0045] Preparation of anti-static coating liquid:

[0046] Water-based carbon nanotube dispersion ML1293 (crystal antibiotic, water-based carbon nanotube dispersion of carbon nanotubes) 15g, modified acrylic resin emulsion 5g, water 78.8 g, oxazoline crosslinking agent WS -700 (Yen Chemical) 0.1g, polyoxyethylene ether moisturizer YL-405 (Yongle Chemical) 0.1g. The high shear emulsifier is uniformly dispersed, which is made into an ant...

Embodiment 2

[0050] Preparation of modified acrylic resin emulsion:

[0051] Acrylic acid, NN'-dimethanolamine, phenol, ethanol, epoxy resin were added to the reactor, and stirred at 80 ° C for 1.5 hours, the rotational speed was 750 rpm, and then the reaction kettle temperature was raised to At 110 ° C, the mixture was stirred for 3.5 hours, and the alkyl alcohol amide polyoxy ether was administered to the reaction kettle, and an appropriate amount of distilled water was added, stirred at a rate of 1900 rpm, and the emulsified reaction was 3.5 hours to obtain a modified polyester emulsion. .

[0052] Preparation of anti-static coating liquid:

[0053] Water-based carbon nanotube dispersion CNT 102 (Dknano, water-based carbon nanotube dispersion) of carbon nanotubes is 8%), 22g, modified acrylic resin emulsion 10g, water 66g, melamine crosslinking agent LF-8500 (rich Resin) 1.5 g, polyoxyethylene ether wetting agent PE-100 (Hengyu Chemical) 0.5 g. The high shear emulsifier is uniformly dispers...

Embodiment 3

[0057] Preparation of modified acrylic resin emulsion:

[0058] Acrylic acid, NN'-dimethyl ethanolamine, phenol, ethanol, epoxy resin were added to the reactor, and stirred at 90 ° C for 2 hours, and the rotational speed was 800 rpm, and then the reaction kettle temperature was raised to At 115 ° C, the stirring reaction was stirred for 4 hours, and the alkyl alcoholamide polyoxy ether was administered to the reaction kettle, and an appropriate amount of distilled water was added, stirred at a rate of 2000 rpm, and the emulsified reaction was 4 hours to obtain a modified polyester emulsion. .

[0059] Preparation of anti-static coating liquid:

[0060] Water-based carbon nanotube dispersion KNS2021080419 (Kanos, water-based carbon nanotube dispersion of carbon nanotubes) 30g, modified acrylic resin emulsion 15g, water 51g, nitrogen gyridine crosslinking agent RP-1 (Hefei Rui) 3G, polyoxyethylene ether moisturizer XP-80 (BASF) 1G. The high shear emulsifier is uniformly dispersed, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com