Non-combustible high-safety sodium ion battery

A sodium-ion battery, high-safety technology, used in secondary batteries, climate sustainability, non-aqueous electrolyte batteries, etc., can solve problems such as hidden dangers, flammability, hinder practical application, etc. Cost, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

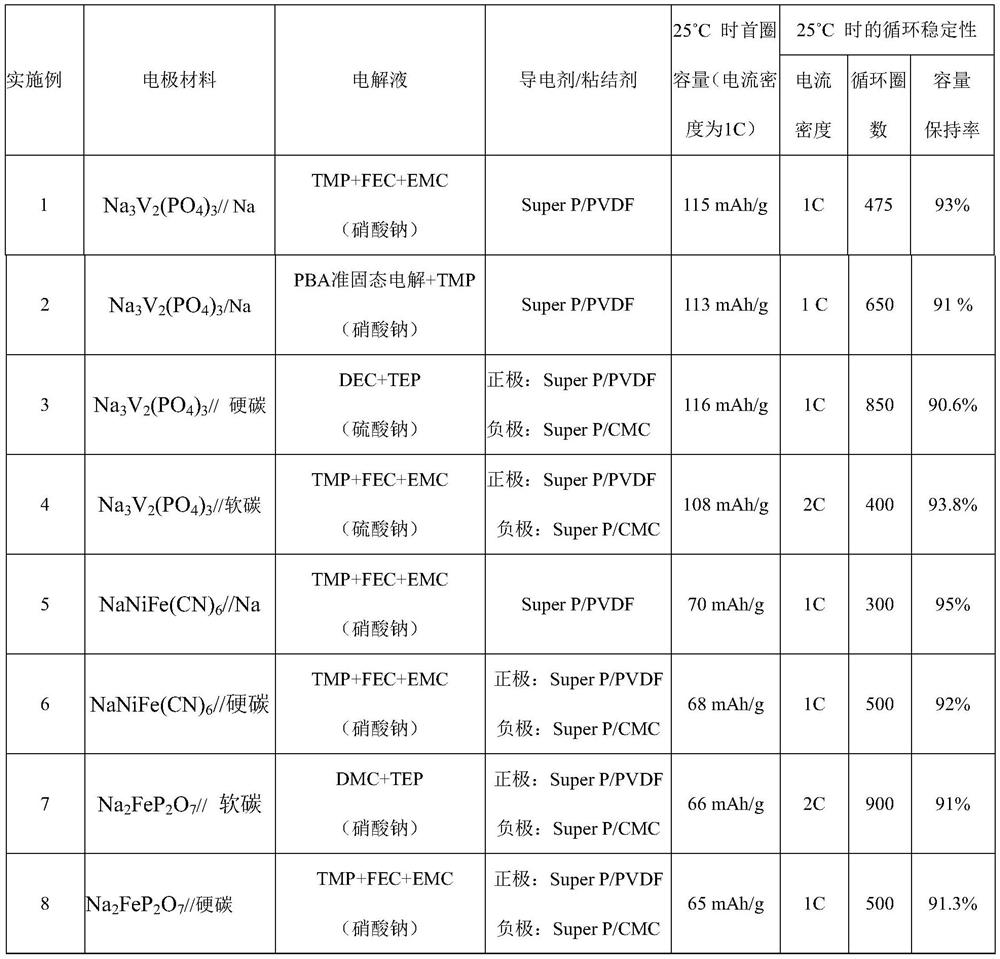

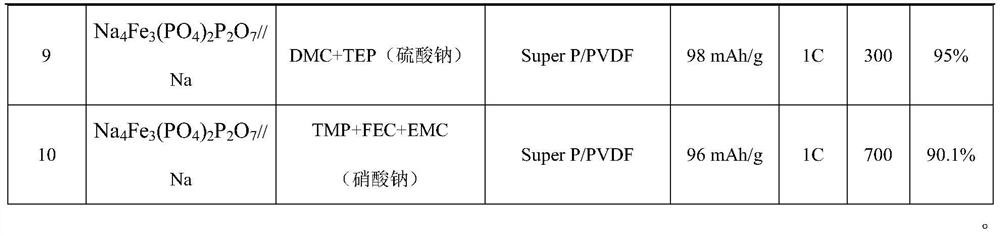

Examples

Embodiment 1

[0022] Trimethyl phosphate (TMP), fluoroethylene carbonate (FEC), and ethyl methyl carbonate (EMC) were mixed according to a volume ratio of 1:1:2, and then sodium nitrate was added to form a 1mol / L solution. Put the prepared electrolyte on the flame of the alcohol lamp for 10 seconds, and the electrolyte is not ignited. Take Na 3 V 2 (PO 4 ) 3 as a positive electrode active material. The preparation of the positive electrode sheet is as follows: according to the active material (Na 3 V 2 (PO 4 ) 3 ): conductive agent (super P): binder (polyvinylidene fluoride PVDF) = 80:10:10 mixed slurry, coated on the surface of carbon-coated aluminum foil to form a positive electrode sheet. Secondly, metal sodium (Na) was used as the negative electrode material, and Celgard 2500 film was used as the separator to assemble a 2032 button battery. At room temperature of 25°C and a current density of 1C, the first-cycle capacity is 115mAh / g. After 475 cycles, the capacity retention rat...

Embodiment 2

[0024] Mix trimethyl phosphate (TMP), fluoroethylene carbonate (FEC), and ethyl methyl carbonate (EMC) in a volume ratio of 1:1:2, and then add 30% volume ratio of acrylic acid to the homogeneous solution Butyl ester monomer, then add sodium nitrate to make a 1mol / L solution. Azobisisobutyronitrile (AIBN) was then dissolved in the solution as a thermal initiator. The resulting solution was injected into glass molds with silicone spacers. Finally, the electrolyte was heated at 70 °C for 12 h to obtain a quasi-solid state highly concentrated electrolyte. Put the prepared quasi-solid electrolyte on the flame of the alcohol lamp for 10 seconds, and the electrolyte is not ignited. Take Na 3 V 2 (PO 4 ) 3 as a positive electrode active material. The preparation of the positive electrode sheet is as follows: according to the active material (Na 3 V 2 (PO 4 ) 3 ): conductive agent (super P): binder (polyvinylidene fluoride PVDF) = 80:10:10 mixed slurry, coated on the surfac...

Embodiment 3

[0026]Mix diethyl carbonate (DEC) and triethyl phosphate (TEP) at a volume ratio of 3:1, and then add sodium sulfate as a solute to prepare an electrolyte solution with a concentration of 1 mol / L. Put the prepared electrolyte on the flame of the alcohol lamp for 10 seconds, and the electrolyte is not ignited. Take Na 3 V 2 (PO 4 ) 3 as a positive electrode active material. The preparation of the positive electrode sheet is as follows: according to the active material (Na 3 V 2 (PO 4 ) 3 ): conductive agent (super P): binder (polyvinylidene fluoride PVDF) = 80:10:10 mixed slurry, coated on the surface of carbon-coated aluminum foil to form a positive electrode sheet. Secondly, hard carbon is used as the negative electrode active material. Hard carbon: conductive agent (super P): binder (sodium carboxymethyl cellulose CMC) = 80:10:10 mixed slurry, coated on the surface of copper foil to form a negative electrode sheet. A 2032 coin cell was assembled using Celgard 2500 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com