Micromechanical resonator and preparation method thereof

A micromechanical resonator and resonator technology, applied in the field of microelectronics, can solve problems such as energy loss, achieve the effect of improving Q value and reducing anchor point loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0067] In the second aspect, the present invention provides a method for preparing a micromechanical resonator. The connecting part of the support beam and the resonator is made by photolithography using a laser direct writing process or a thermal reflow process, or using a laser or ion beam without masking It is manufactured by film etching; the above-mentioned micro-mechanical resonator is prepared by adopting the preparation method of the micro-mechanical resonator.

[0068] (1) The prepared micromechanical resonator is a capacitive resonator, and the preparation method comprises the following steps:

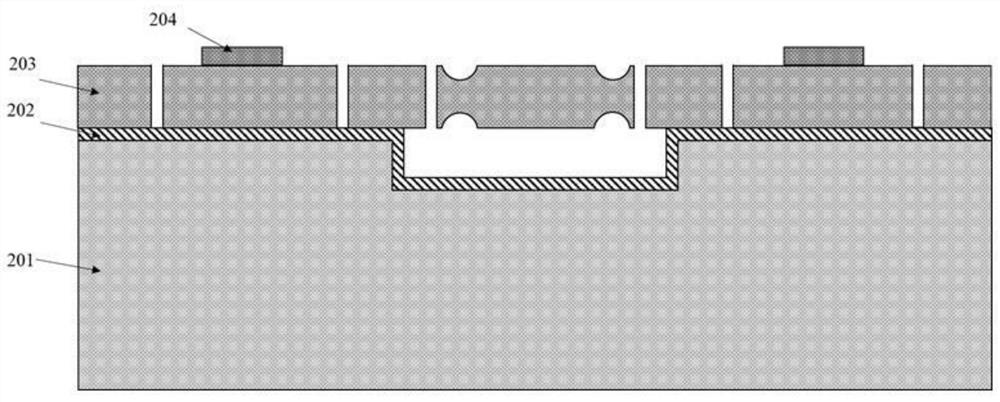

[0069] Step 1, etching a cavity structure on the substrate silicon wafer, and growing a buried oxide layer on the surface of the substrate silicon wafer;

[0070] Step 2, photoetching and patterning the lower surface of the device layer silicon to form a structure in which the size of the lower surface of the device layer silicon varies in the thickness direction;

[0071] S...

Embodiment 1

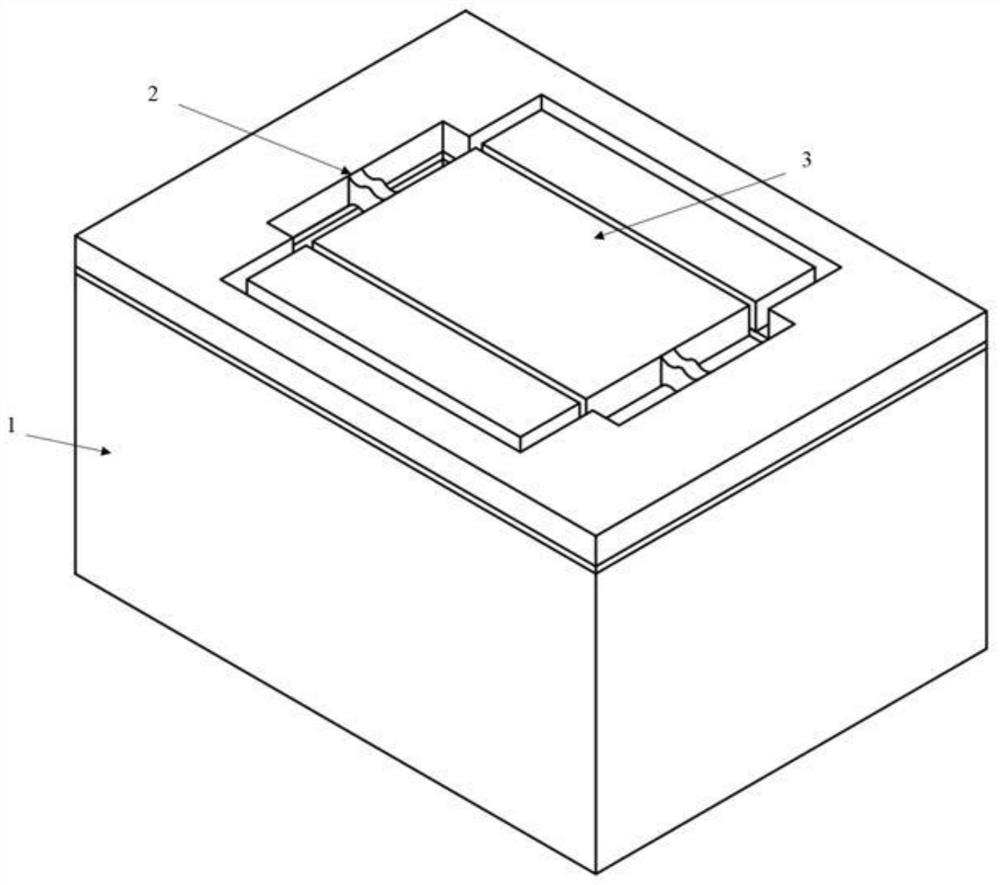

[0101] figure 1 It is shown that the resonant oscillator provided by Embodiment 1 is a capacitive resonator with a thin film structure of single crystal silicon.

[0102] Specifically, a micromechanical resonator includes a substrate silicon chip 1 and a resonator structure, the front side of the substrate silicon chip 1 is provided with a cavity structure; the resonator structure includes a resonant oscillator 3 and a support beam 2 .

[0103] The resonant oscillator 3 is suspended above the cavity structure, and the resonant oscillator 3 is connected to the silicon substrate 1 through the support beam 2 .

[0104] The support beam 2 is located at the boundary of the resonant oscillator 3, and the thickness direction of the connection between the support beam 2 and the resonant oscillator 3 is gradual, specifically, the upper and lower surfaces of the support beam 2 have a concave geometry. structure.

[0105] The cross-section of the support beam 2 is a Boolean subtraction...

Embodiment 2

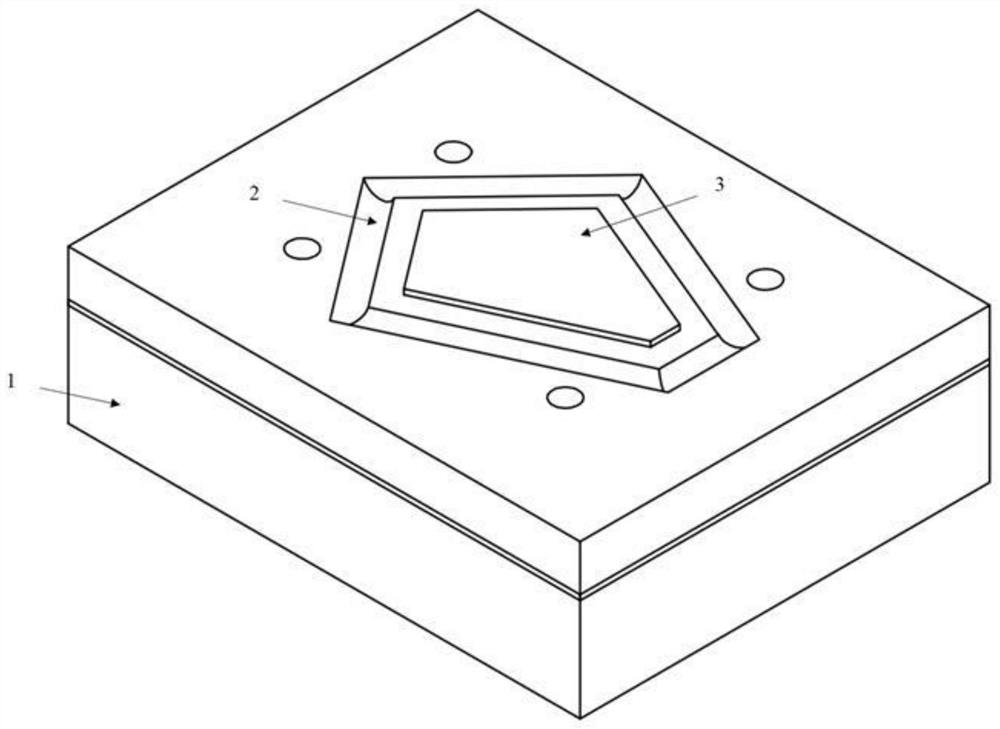

[0114] image 3 It is shown that the resonant vibrator provided in Embodiment 2 is a piezoelectric resonator with a metal-piezoelectric layer-metal composite film structure.

[0115] The difference from the first embodiment is that the resonant oscillator 3 in the first embodiment is a single structure including single crystal silicon, the resonant oscillator 3 is a rectangular plate, and the micromechanical resonator is a capacitive resonator. In Embodiment 2, the resonant vibrator 3 is a composite film structure including metal-piezoelectric layer-metal, the resonant vibrator 3 is a polygonal plate, the support beam 2 is located at the vibration node, the number of support beams 2 is multiple, and the resonance Vibrator 3 is connected to substrate silicon chip 1 through support beam 2; the micromechanical resonator is a piezoelectric resonator, and the material of the piezoelectric layer is quartz, aluminum nitride, scandium-doped aluminum nitride, zinc oxide , any one of l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com