Transparent thermoplastic resin composition and molded article thereof

A technology of thermoplastic resin and composition, which is applied in the field of transparent thermoplastic resin composition, can solve the problems of insufficient balance and limitation of transparency, impact resistance, fluidity and mold pollution, and achieve good mold pollution and good color tone , highly transparent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

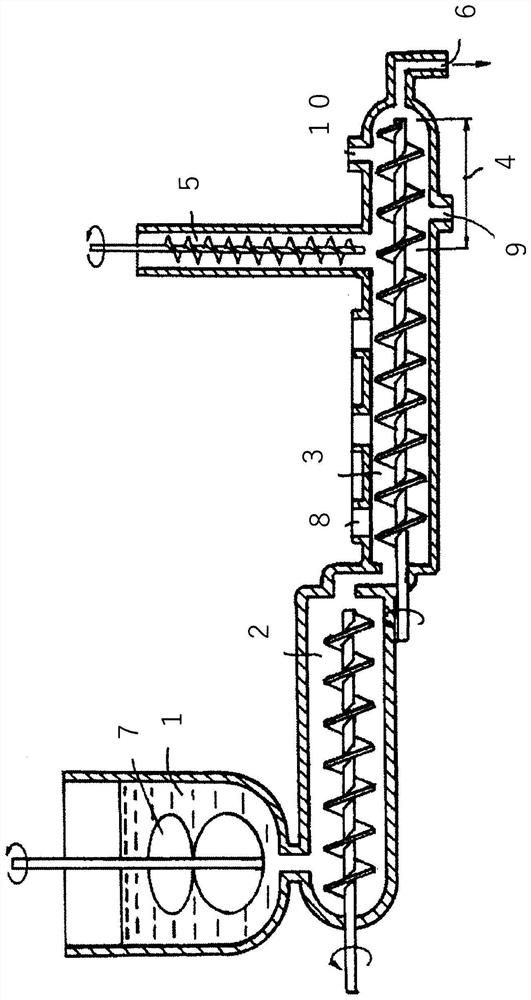

Method used

Image

Examples

Embodiment

[0132] Hereinafter, although an Example is given and this invention is described in more detail, this invention is not limited to these Examples, and is interpreted. First, the evaluation method will be described.

[0133] (1) Mass average particle size of rubbery polymer

[0134] After diluting and dispersing the latex of the rubbery polymer (r) in an aqueous medium, the particle size distribution was measured with a laser scattering diffraction particle size distribution measuring device "LS 13 320" (Beckman Coulter Co., Ltd.). The mass average particle diameter of the rubbery polymer (r) was calculated from this particle diameter distribution.

[0135] (2) Refractive index of rubbery polymer (r)

[0136] While stirring 150 ml of methanol at 300 rpm, 10 ml of emulsified rubber latex was added, and then 20 ml of sulfuric acid adjusted to 10% by mass was added to obtain a precipitate of a rubbery polymer (r). The precipitate of the rubbery polymer (r) was dried under reduce...

manufacture example 1

[0184] (Manufacture example 1) graft copolymer (A-1)

[0185] In a four-neck flask with an internal capacity of 5 liters equipped with a stirring blade, 50 parts by mass (solid content conversion) of polybutadiene latex (mass average particle diameter of rubber: 0.30 μm, refractive index: 1.516), 130 parts by mass of pure water, 0.4 parts by mass of sodium laurate, 0.2 parts by mass of glucose, 0.2 parts by mass of sodium pyrophosphate, and 0.01 parts by mass of ferrous sulfate. After nitrogen replacement, the temperature was adjusted to 60°C, and 3.0 parts by mass of styrene was initially added over 45 minutes while stirring. parts, a monomer mixture of 12.0 parts by mass of methyl methacrylate and 0.16 parts by mass of tert-dodecylmercaptan.

[0186] Next, an initiator mixture of 0.3 parts by mass of cumene hydroperoxide, 1.6 parts by mass of sodium laurate as an emulsifier, and 25 parts by mass of pure water was continuously added dropwise over 4 hours. Simultaneously, a m...

manufacture example 2

[0187] (Manufacture example 2) graft copolymer (A-2)

[0188] Into a four-neck flask with an internal capacity of 5 liters equipped with a stirring blade, 50 parts by mass (solid content conversion) of polybutadiene latex (rubber mass average particle diameter 0.30 μm, refractive index 1.516), 130 parts by mass of pure water, and laurel 0.4 parts by mass of sodium bicarbonate, 0.2 parts by mass of glucose, 0.2 parts by mass of sodium pyrophosphate, and 0.01 parts by mass of ferrous sulfate. After nitrogen substitution, the temperature was adjusted to 60°C, and 2.5 parts by mass of styrene was initially added over 45 minutes while stirring. , a monomer mixture of 2.0 parts by mass of acrylonitrile, 10.5 parts by mass of methyl methacrylate, and 0.16 parts by mass of t-dodecylmercaptan.

[0189] Next, an initiator mixture of 0.3 parts by mass of cumene hydroperoxide, 1.6 parts by mass of sodium laurate as an emulsifier, and 25 parts by mass of pure water was continuously added d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mass average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com