Method for preparing separation membrane by using small molecular monomer

A technology for separating membranes and small molecules, applied in semipermeable membrane separations, chemical instruments and methods, membranes, etc., can solve the problems of wasting solvents, water resources and time, prolonging the production cycle of materials, and taking a long time in the dissolution process. Waste of organic solvents, reduction of production and waste of energy resources, and the effect of shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

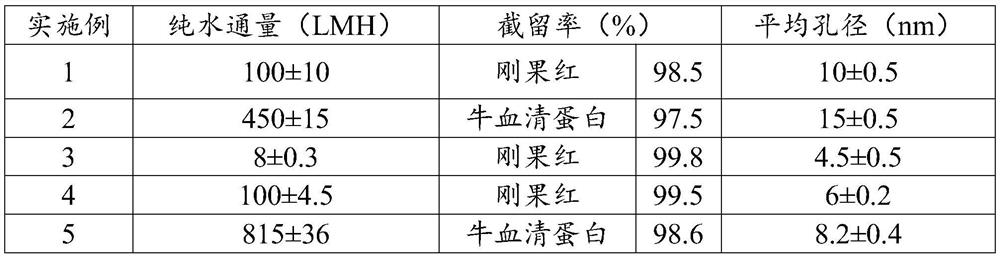

Examples

Embodiment 1

[0038] A method of preparing (polyether sulfone) separation membrane is prepared using small molecular monomers, including the steps of:

[0039] (1) In an inert gas atmosphere, 2.0 mol of bisphenol S, 2.04 mol 4,4'-dichlorobenyl sulfone and potassium carbonate were added to the 5L reaction vessel, using Schlenk technology to remove oxygen in the reaction system. 3 l of cyclobutolane and 0.5 L toluene were added, and the system was heated to 140 ° C for 12 h, and the moisture in the system was removed; the system was heated to 210 ° C constant temperature reaction for 8 h, resulting in polyethersulfone having a number average molecular weight of 30000 da (where PDI = 1.52);

[0040] (2) Add a polyether sulfone to the online filter, filtration using a polytetrafluoroethylene film having a average pore diameter of 5 μm, removes salt particles to obtain a clear solution;

[0041] (3) 5% of the total mass of the die foundation (PVP-K50) is added to the clear solution and uniform, and ...

Embodiment 2

[0044] The method of preparing (polysulfone) separation membrane is prepared using small molecular monomers, and specifically includes the following steps:

[0045] (1) In an inert gas atmosphere, 4.0 mol of bisphenol A, 4.08 mol 4,4'-dichlorobenyl sulfone and potassium carbonate were added to a 10L reactor, and the oxygen in the reaction system was removed using Schlenk technology. 6 l N, N-dimethylacetamide and 1.5 L toluene were added, and the system was heated to 150 ° C for 12 h, removing moisture in the system; then heating the system to 165 ° C constant temperature reaction for 8 h, resulting in several average molecular weight The polysulfone (wherein PDI = 1.40) is 40000 da.

[0046] (2) Filtration of polysulfone is filtered from the chromatography in the chromatography column using 200 mesopolite soil, and the salt particles are removed, and the clear solution is obtained;

[0047] (3) Add 10%, polyethylene glycol (PEG2000) having a total molecular weight of 2000 Da, and...

Embodiment 3

[0050] The method of separating the film by the small molecular monomer (PSF-B-PEG block copolymer) separation membrane, specifically includes the steps of:

[0051] (1) In an inert gas atmosphere, 1.5 mol of bisphenol A, 1.5 mol 4, 4'-dichlorobenyl sulfone and 6 mol of potassium carbonate were added to the 5L reactor, and the oxygen in the reaction system was removed using Schlenk technology. 2.5 Ln, N-dimethylacetamide and 1 L toluene were added, first heated to heat the system to 150 ° C dehydration treatment for 12h, removing moisture in the system; heating the system heating the system to 165 ° C constant temperature reaction 8h; finally controlled the system At 165 ° C, a polyethylene glycol having a 26.4 g of a molecular weight of 400 dA was added, and the constant temperature reaction was prepared to obtain a PSF-B-PEG block copolymer having a PEG content of 13 wt% (wherein Mn = 42000 Da, PDI = 1.65);

[0052] (2) The PSF-B-PEG block copolymer was filtered according to a 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| number average molecular weight | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com