Organic-inorganic composite flocculant and preparation method thereof

An inorganic composite, flocculant technology, applied in chemical instruments and methods, flocculation/sedimentation water/sewage treatment, water/sludge/sewage treatment, etc. It can improve chemical stability, enhance flocculation effect and strong adsorption capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

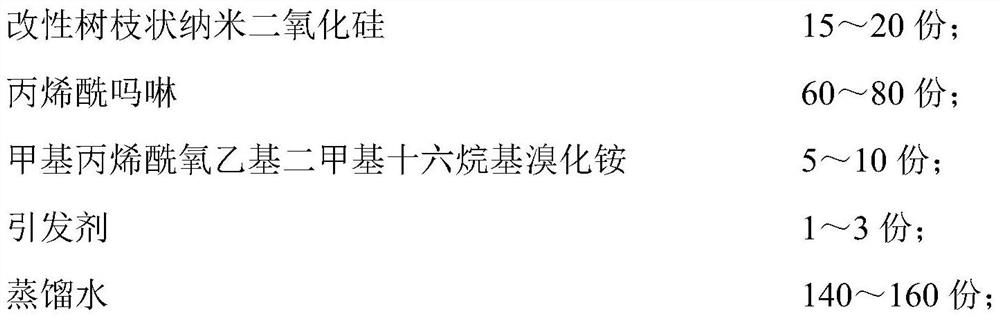

[0036] An organic-inorganic composite flocculant prepared from the following components in parts by weight:

[0037]

[0038]

[0039] The preparation method steps of above-mentioned organic-inorganic composite flocculant are as follows:

[0040] (1) Preparation of modified dendritic nano-silica:

[0041] a. Preparation of dendritic nano-silica: Add 30.2 g of tetraethyl orthosilicate and 54.3 g of absolute ethanol into reactor A, keep the temperature at 30° C., and fully stir to form a solution. Add 70.5 g of deionized water, 0.2 g of cetyltrimethylammonium bromide, and 0.5 g of urea into reactor B, stir well and mix with the solution in reactor A to form a reaction mother liquor. The mother liquor is hydrothermally synthesized in a homogeneous reactor, heated to 120-125°C, reacted for 4 hours, and the stirring speed is 60r / min to obtain a stable white emulsion.

[0042] The obtained white emulsion was centrifuged, washed three times with acetone and deionized water, a...

Embodiment 2

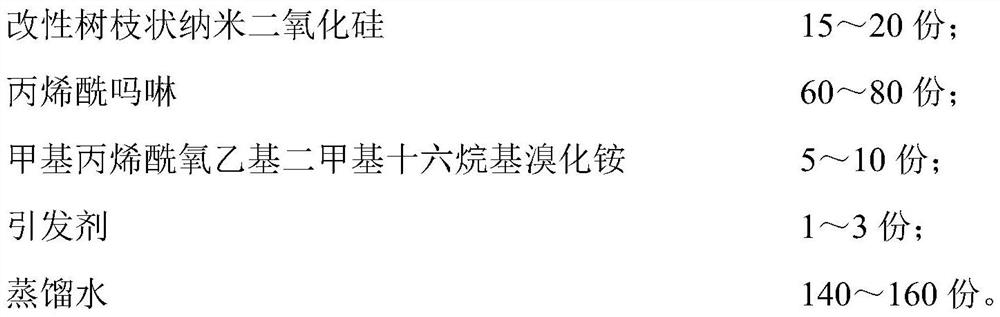

[0046] An organic-inorganic composite flocculant prepared from the following components in parts by weight:

[0047]

[0048] The preparation method steps of above-mentioned organic-inorganic composite flocculant are as follows:

[0049] (1) Preparation of modified dendritic nano-silica:

[0050] a. Preparation of dendritic nano-silica: Add 30.2 g of tetraethyl orthosilicate and 60.4 g of absolute ethanol into reactor A, keep the temperature at 35° C., and fully stir to form a solution. Add 70 g of deionized water, 0.62 g of cetyltrimethylammonium bromide, and 1.1 g of urea into Reactor B, and mix them with the solution in Reactor A after fully stirring to form a reaction mother liquor. The mother liquor is hydrothermally synthesized in a homogeneous reactor, the temperature is raised to 120-125° C., and the reaction is carried out for 4.5 hours. The stirring speed is 60 r / min, and a stable white emulsion is obtained.

[0051] The obtained white emulsion was centrifuged, ...

Embodiment 3

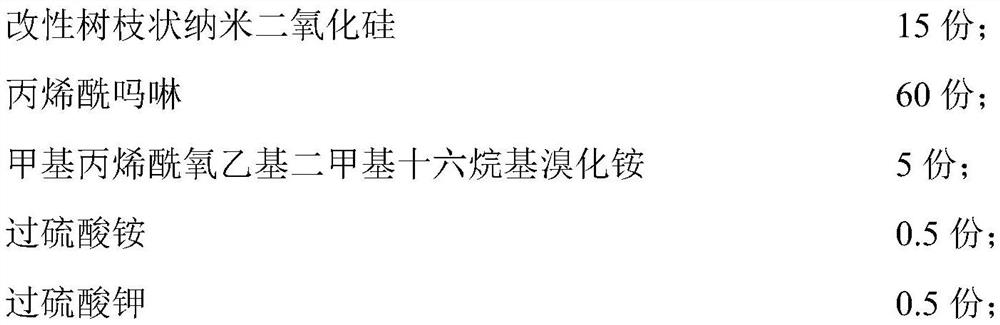

[0055] An organic-inorganic composite flocculant prepared from the following components in parts by weight:

[0056]

[0057] The preparation method steps of above-mentioned organic-inorganic composite flocculant are as follows:

[0058] (1) Preparation of modified dendritic nano-silica:

[0059] a. Preparation of dendritic nano-silica: Add 30.2 g of tetraethyl orthosilicate and 66.4 g of absolute ethanol into reactor A, keep the temperature at 40° C., and fully stir to form a solution. Add 70 g of deionized water, 1.2 g of cetyltrimethylammonium bromide, and 2.6 g of urea into reactor B, stir well and mix with the solution in reactor A to form a reaction mother liquor. The mother liquor is hydrothermally synthesized in a homogeneous reactor, heated to 120-125°C, reacted for 5 hours, and the stirring speed is 60r / min to obtain a stable white emulsion.

[0060] The obtained white emulsion was centrifuged, washed three times with acetone and deionized water, and dried at 70...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com